Mobile:+86-311-808-126-83

Email:info@ydcastings.com

anchor type impeller

Understanding Anchor Type Impellers Design and Application

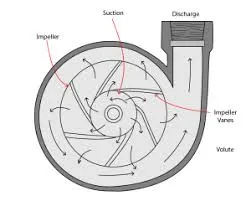

In the vast field of fluid dynamics, the design of impellers plays a crucial role in various applications, especially in mixing and pumping processes. Among the different types of impellers, the anchor type impeller stands out due to its unique design and functionality. This article explores the anchor type impeller, its design characteristics, operating principles, and applications across diverse industries.

Design Characteristics

The anchor type impeller is specifically designed for mixing highly viscous fluids. Its structure typically resembles an anchor, featuring long blades that extend out from a central hub. These blades are flat and are positioned at an angle, allowing them to create a strong flow and minimize dead zones within the mixing vessel. The unique geometry ensures that the impeller has a large surface area, which helps in effective mixing of materials with different viscosities.

One of the distinct features of the anchor type impeller is its ability to scrape the walls of the mixing vessel. This scraping action prevents the buildup of material on the vessel’s walls, ensuring a uniform blend of components while reducing the likelihood of product degradation due to stagnant zones. Furthermore, anchor impellers are often used in vessels with a height-to-diameter ratio that is not favorable for traditional impellers, making them versatile for various tank geometries.

Operating Principles

The operational efficiency of anchor type impellers is based on two primary mechanisms axial and radial flow. As the impeller rotates, it generates a large volume of fluid movement in both directions. The blades push the fluid downward, creating a strong axial flow that promotes thorough mixing. Concurrently, the radial flow generated by the impeller’s shape helps to circulate the fluid back toward the center, thus enhancing the overall mixing efficiency.

anchor type impeller

The effectiveness of the anchor type impeller can also be attributed to its speed and power input. For high-viscosity fluids, slower rotational speeds are typically required to prevent excessive shear and aeration, which could lead to product damage. However, the design of the anchor ensures that adequate mixing occurs even at these lower speeds, allowing for optimal process conditions without compromising product integrity.

Applications

Anchor type impellers find extensive application in various industries due to their ability to handle viscous materials. In the food industry, they are commonly used for mixing sauces, creams, and other viscous products where uniformity is critical. Similarly, in the pharmaceutical sector, anchor impellers are utilized for mixing ointments, gels, and pastes, ensuring that active ingredients are evenly distributed.

Chemical manufacturing also benefits from the use of anchor type impellers. Various processes, such as polymer mixing or the preparation of emulsions and suspensions, require thorough blending of high-viscosity substances, making anchor impellers an ideal choice. Additionally, industries that handle paints, coatings, and adhesives leverage the capability of anchor type impellers to ensure consistency and quality in their products.

Conclusion

The anchor type impeller is a vital component in the realm of fluid mixing, particularly suited for challenging applications involving high-viscosity fluids. Its unique design and operational advantages make it an essential tool across various industries, from food production to pharmaceuticals and chemical manufacturing. As processes evolve and demands for efficiency and quality increase, anchor type impellers continue to play a crucial role in delivering consistent and reliable mixing solutions, ensuring product quality and operational excellence. Understanding the intricacies of anchor type impellers not only aids in selecting the right equipment for specific applications but also fosters innovation in design and application throughout the industry.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025