Mobile:+86-311-808-126-83

Email:info@ydcastings.com

aluminum casting foundry

Aluminum Casting Foundry An Overview

Aluminum casting foundries play a crucial role in various industries, producing components vital for automotive, aerospace, electronics, and many other sectors. The process of transforming aluminum into functional parts involves various methods and techniques, each designed to meet specific requirements regarding quality, precision, and cost-effectiveness.

The Significance of Aluminum

Aluminum is a popular material across industries due to its combination of desirable properties light weight, high strength, excellent corrosion resistance, and good thermal and electrical conductivity. These attributes make it an ideal choice for a wide range of applications, from lightweight automotive parts that improve fuel efficiency to conductive components in electronic devices.

Types of Aluminum Casting Processes

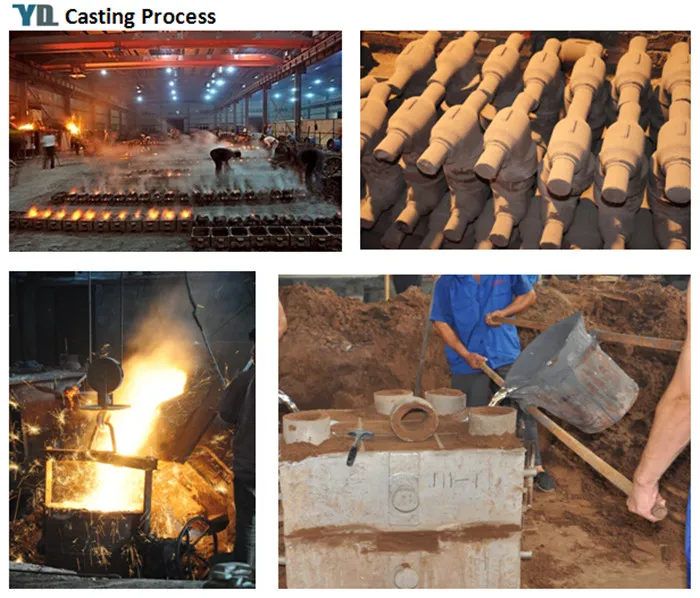

There are several primary techniques used in aluminum casting, including sand casting, die casting, gravity casting, and investment casting. Each method has its own unique advantages and is chosen based on the specific requirements of the final product.

1. Sand Casting This is one of the oldest and most widely used casting methods. In sand casting, a mold is created from sand. Molten aluminum is poured into the mold where it solidifies to form a part. This method is well-suited for producing large and complex shapes with relatively low setup costs. However, it may not offer the same precision as other methods.

2. Die Casting Die casting involves forcing molten aluminum into a mold under high pressure. This process allows for high-volume production and yields parts with excellent surface finish and dimensional accuracy. Die casting is commonly used in the automotive industry for components such as engine blocks, transmission cases, and various structural parts.

3. Gravity Casting As the name suggests, gravity casting relies on gravity to fill the mold with molten aluminum. This method is often used for larger castings where detailed shapes are required. While it may not achieve the precision of die casting, gravity casting can produce high-quality components at a lower cost.

4. Investment Casting Also known as lost-wax casting, this technique involves creating a wax model of the part, coating it in a ceramic shell, and then melting away the wax to leave a mold. This process is ideal for producing intricate shapes and fine details, making it suitable for aerospace and medical device applications.

aluminum casting foundry

Advantages of Aluminum Casting

The aluminum casting process offers several benefits

- Cost-Effective When producing large quantities, aluminum casting can be highly economical, particularly with die casting and sand casting processes. The ability to produce complex shapes reduces the need for additional machining, thereby lowering production costs.

- Design Flexibility Aluminum casting allows for the creation of intricate designs that can enhance product functionality. From thin walls to complex geometries, the design possibilities are vast, enabling engineers to innovate and develop advanced products.

- Rapid Production Many casting methods, particularly die casting, facilitate rapid production cycles. This enables manufacturers to respond quickly to market demands and reduce lead times.

- Recyclability Aluminum is 100% recyclable without loss of quality. This characteristic is increasingly valuable as industries seek to adopt more sustainable practices.

Quality Assurance in Aluminum Casting

Quality control is essential in aluminum casting foundries. It typically involves rigorous testing and inspection to ensure that castings meet specific standards and tolerances. Techniques such as X-ray inspection, ultrasonic testing, and chemical analysis are employed to detect defects, ensure structural integrity, and confirm that the material composition meets requirements.

Conclusion

Aluminum casting foundries are vital in modern manufacturing, providing a diverse range of high-quality components that serve many industries. With ongoing advancements in casting technology and a growing emphasis on sustainability, the future of aluminum casting looks promising. As more companies recognize the benefits of aluminum as a lightweight, durable, and environmentally friendly material, the demand for innovative casting solutions will continue to rise, driving the industry forward. In the face of evolving market needs, aluminum casting foundries remain a cornerstone of engineering and manufacturing excellence.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025