Mobile:+86-311-808-126-83

Email:info@ydcastings.com

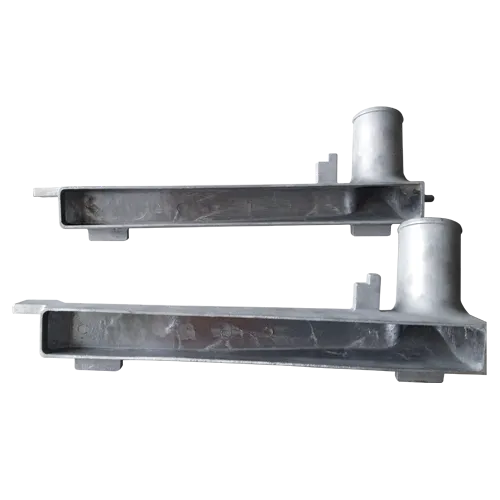

aluminium alloy die casting

The Importance of Aluminum Alloy Die Casting in Modern Manufacturing

Aluminum alloy die casting has become a critical process in the modern manufacturing landscape, revolutionizing how components are produced across various industries. This method involves pouring molten aluminum alloy into a mold under high pressure, allowing for the creation of intricate shapes with excellent dimensional accuracy. The advantages of this process make it the preferred choice for manufacturers seeking efficiency, cost-effectiveness, and versatility.

One of the primary benefits of aluminum alloy die casting is its ability to produce lightweight components. Aluminum is significantly lighter than other metals, making it an ideal choice for industries where weight reduction is crucial, such as automotive and aerospace. The lightweight nature of aluminum allows for improved fuel efficiency in vehicles and enhanced performance in aircraft.

The Importance of Aluminum Alloy Die Casting in Modern Manufacturing

Aluminum alloy die casting also enables high production rates with minimal waste. The process allows for the mass production of complex parts, reducing labor costs and production time. Manufacturers can produce thousands of identical components quickly and with less scrap material compared to other casting methods. This efficiency not only streamlines production but also contributes to a reduced environmental footprint, making it a more sustainable option.

aluminium alloy die casting

Moreover, aluminum alloy die castings are known for their excellent surface finish and precision. The high-pressure injection of molten alloy into the mold results in intricate designs that often require little to no additional machining. This feature is particularly advantageous in industries where aesthetics matter, such as consumer electronics and automotive interiors, where the appearance of a product can significantly influence consumer choice.

The versatility of aluminum alloy die casting extends to various applications. From engine blocks and transmission housings in the automotive industry to intricate components in home appliances, medical devices, and electronic products, the potential uses are vast. This adaptability makes aluminum alloy die castings a valuable solution across multiple sectors.

As technology advances, the future of aluminum alloy die casting looks promising. Innovations such as enhanced mold designs, better alloys, and automated production processes continue to improve efficiency and product quality. Additionally, the growing emphasis on lightweight materials in response to global sustainability initiatives is likely to further drive the demand for aluminum die cast components.

In conclusion, aluminum alloy die casting stands out as a significant manufacturing process that provides numerous advantages, including lightweight construction, strength, speed, and versatility. As industries increasingly prioritize efficiency and sustainability, aluminum die casting will play a pivotal role in shaping the future of production, offering innovative solutions to meet the demands of an ever-evolving market. The ongoing advancements in this field ensure that aluminum alloy die casting will remain a cornerstone of modern manufacturing for years to come.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025