Mobile:+86-311-808-126-83

Email:info@ydcastings.com

A320 Impeller Design and Performance Analysis for Enhanced Aircraft Efficiency

The A320 Impeller A Crucial Component in Aviation

In the world of aviation, the performance and efficiency of an aircraft largely depend on its engine systems. Among the vital components that contribute to the functionality of jet engines is the impeller. This article focuses on the A320 impeller, a critical part that plays an essential role in the performance of the Airbus A320 family of aircraft.

The A320 is a popular narrow-body airliner that has revolutionized commercial aviation since its introduction in 1988. Known for its fuel efficiency, advanced technology, and comfortable cabin, the A320 family has become a staple choice for airlines across the globe. At the heart of its successful performance are the engines, particularly the turbofan engines that power the aircraft. The impeller is a key element in these engines, specifically in the compressor section.

The A320 Impeller A Crucial Component in Aviation

The A320 typically comes equipped with several engine options, including the CFM56 and the IAE V2500 engines. Both of these engines use advanced impeller designs to maximize efficiency and performance. The CFM56, for instance, utilizes a fan diameter of up to 1.5 meters and incorporates advanced materials that allow for lighter and more durable impeller construction. This design enhances thrust while minimizing fuel consumption, making the A320 one of the most efficient aircraft in its class.

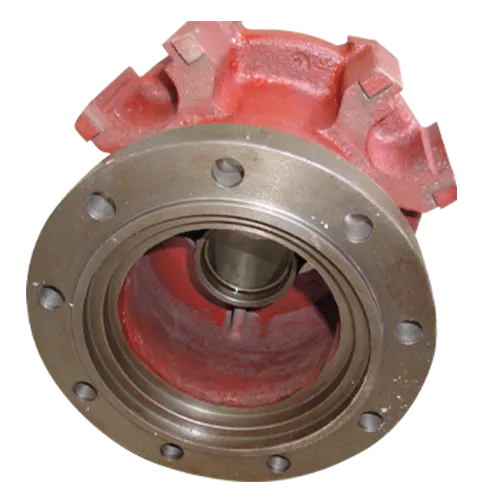

a320 impeller

The performance of the A320 impeller extends beyond mere functionality; it also plays a role in the overall sustainability of aviation. With a growing emphasis on reducing carbon emissions and environmental impact, manufacturers are continuously innovating ways to improve engine technology. The impeller's design is a focal point in these efforts, as advancements can lead to more efficient engines, ultimately reducing the carbon footprint of the A320.

Aerodynamic efficiency is another critical aspect of the A320 impeller design. Engineers meticulously design the shape of the impeller blades to ensure smooth airflow, reducing turbulence and drag. This attention to aerodynamic detail not only enhances performance but also contributes to operational noise reduction, making the A320 a quieter aircraft for passengers and those living near airports.

Maintenance and durability are also vital considerations for the A320 impeller. Given the rigorous operating conditions that engines face, impellers must be built from high-quality, durable materials that can withstand extreme temperatures and pressures. Regular inspections and maintenance practices are essential to ensure the longevity and reliability of the impeller, thereby optimizing engine performance and safety.

In conclusion, the A320 impeller is a fundamental component that significantly contributes to the aircraft's efficiency, performance, and environmental sustainability. Its innovative design and engineering play a pivotal role in shaping the operational capabilities of the A320 family. As the aviation industry continues to evolve, the development of more advanced impeller technology will remain at the forefront, driving further improvements in aircraft performance and sustainability for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025