Mobile:+86-311-808-126-83

Email:info@ydcastings.com

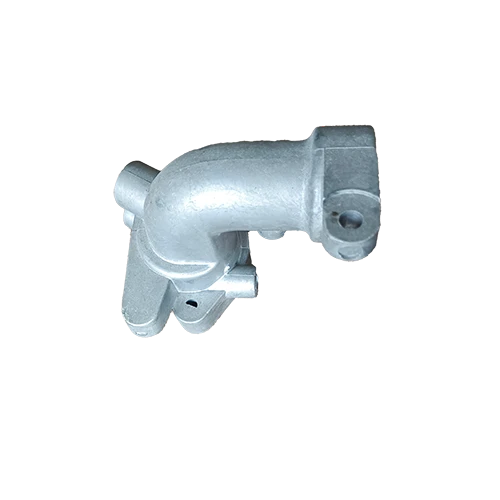

3 8 threaded cap

The Importance of the 3% 208 Threaded Cap in Industrial Applications

In various industrial settings, even the smallest components can play a significant role in ensuring efficiency and reliability. One such component is the 3% 208 threaded cap, which serves an essential function in a range of applications, from water systems to chemical manufacturing. Understanding its characteristics and applications can help industries optimize their operations and improve safety standards.

Design and Features

The 3% 208 threaded cap derives its name from its specific design and composition. The 3% refers to the percentage of an alloy element, typically, which enhances the overall strength and durability of the cap. The 208 indicates a particular thread size, allowing it to be easily integrated into systems requiring secure and tight fittings.

Typically made from materials such as stainless steel, plastic, or other corrosion-resistant substances, the threaded cap is designed to withstand various pressures and temperatures. This durability is crucial in environments where substances can be aggressive or corrosive, such as in chemical processing. The design of the threaded cap also ensures that it can be easily installed and removed, allowing for efficient maintenance and operational flexibility.

Applications

One of the most common applications of the 3% 208 threaded cap is in plumbing and water systems. In these environments, the cap is used to seal pipes and prevent leaks, thus maintaining the integrity of the water system. A malfunction in this area can lead to significant water loss and require costly repairs, making the reliability of the threaded cap critical.

3 8 threaded cap

In the automotive industry, threaded caps are used in various fluid systems, including fuel lines, cooling systems, and hydraulic applications. The cap ensures that these systems are sealed tight, preventing leaks that could lead to performance issues or damage to the vehicle. In high-stress situations, such as racing or heavy-duty transportation, the reliability of these caps becomes even more pronounced.

The manufacturing sector also relies heavily on threaded caps to seal machinery and equipment. Whether in pneumatic systems or machinery housing, a secure seal is necessary to prevent contamination and maintain optimal performance. The 3% 208 threaded cap's robust design helps reduce the risk of failures that could halt production and incur financial losses.

Advantages

The advantages of using a 3% 208 threaded cap extend beyond simple functionality. Its high strength-to-weight ratio means that it can provide excellent sealing capabilities without adding excessive weight to the system. Additionally, the corrosion resistance of commonly used materials extends the lifespan of machinery and piping systems, ultimately leading to lower replacement costs and reduced downtime.

Moreover, these caps are compatible with a myriad of other fittings and valves, enhancing compatibility across various systems. This versatility makes the 3% 208 threaded cap an invaluable component in diverse industrial applications.

Conclusion

The 3% 208 threaded cap may seem like a minor component in the vast landscape of industrial equipment, but its role is undeniably critical. From ensuring leak-proof connections in plumbing systems to maintaining performance in automotive and manufacturing applications, these caps contribute to reliability, efficiency, and safety. As industries continue to seek optimization and improvement in operational practices, components like the 3% 208 threaded cap will remain at the forefront, supporting advancements and innovations across various fields. Investing in quality threaded caps is essential, as it significantly influences the overall performance and longevity of industrial systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025