Mobile:+86-311-808-126-83

Email:info@ydcastings.com

304 stainless steel casting

Understanding 304 Stainless Steel Casting

304 stainless steel is one of the most commonly used grades of stainless steel, particularly in applications where excellent corrosion resistance is a requirement. This alloy, consisting of 18% chromium and 8% nickel, is known for its versatility and adaptability in a wide range of environments, which makes it an ideal choice for casting.

Properties of 304 Stainless Steel

The unique properties of 304 stainless steel make it suitable for various casting applications. Its high corrosion resistance is one of its primary benefits, allowing it to withstand harsh conditions, including exposure to chemicals, acids, and salty environments. Additionally, 304 stainless steel offers good formability and weldability. This means it can be molded into different shapes and forms without cracking, making it favorable for intricate cast designs.

Another notable characteristic of 304 stainless steel is its durability. The material can endure high temperatures, maintaining structural integrity in both cold and hot environments. This property is particularly important in industries such as food processing, pharmaceuticals, and construction, where equipment is often subjected to extreme conditions.

Manufacturing Process of 304 Stainless Steel Casting

The casting process of 304 stainless steel involves several critical steps. First, the alloy is melted at high temperatures in a furnace to produce a molten form. This molten steel is then poured into molds, where it is allowed to cool and solidify into the desired shape. Various casting methods can be employed, including sand casting, investment casting, and die casting, each offering distinct advantages depending on the application and desired precision.

304 stainless steel casting

After the casting process, the components are often subjected to heat treatment and surface finishing to enhance their mechanical properties and appearance. Heat treatment processes like annealing can help relieve internal stresses and improve the alloy's ductility, while surface finishing techniques such as polishing or passivation can enhance corrosion resistance further.

Applications of 304 Stainless Steel Castings

The utilization of 304 stainless steel castings spans across a multitude of industries. In the food and beverage industry, 304 stainless steel is frequently used in the manufacturing of equipment like tanks, piping, and valves, which require a high level of hygiene and resistance to corrosion. Its ability to withstand cleaning agents and high temperatures makes it the ideal choice for restaurants and food processing plants.

In the architectural field, 304 stainless steel is used in various structural components and decorative elements, providing both durability and aesthetic appeal. In chemical processing industries, the alloy's resistance to aggressive substances allows it to be used in compressors, agitators, and storage tanks, ensuring safety and longevity.

Conclusion

In summary, 304 stainless steel casting is an essential aspect of modern manufacturing, offering a combination of resilience, formability, and corrosion resistance. Its broad applicability across various industries underscores its importance as a material of choice for engineers and manufacturers. As technology advances, the processes and applications of 304 stainless steel casting are likely to evolve, contributing to innovations that will continue to enhance performance and efficiency in numerous fields. Understanding its properties and applications can provide valuable insights for businesses looking to optimize their production processes while maintaining high standards of quality and durability.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

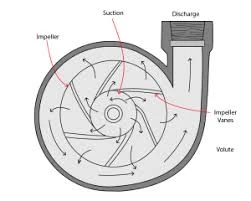

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025