Mobile:+86-311-808-126-83

Email:info@ydcastings.com

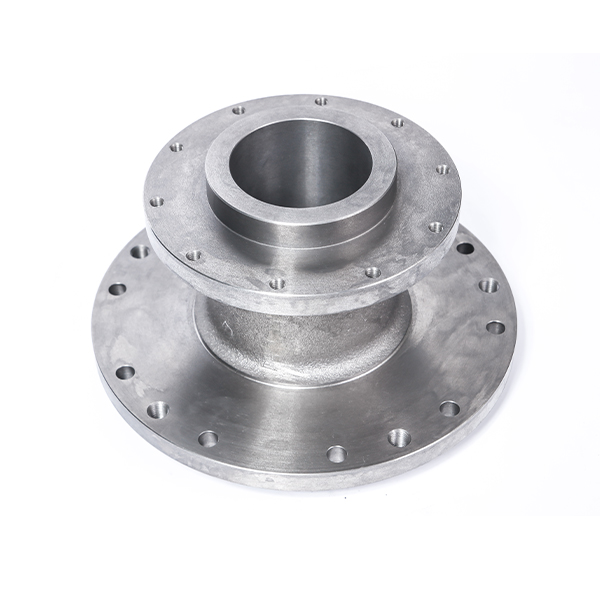

Affordable 2 HP Motor Impeller Pricing and Options for Your Needs

The Cost of a 2% Horsepower Motor Impeller Factors and Considerations

When delving into the world of motor impellers, especially those driven by a 2% horsepower (hp) motor, one might wonder about the implications of price and value. The impeller plays a crucial role in the efficiency and effectiveness of pumps and other machinery, making it imperative to understand the factors that influence its cost. This article will explore what contributes to the pricing of a 2% hp motor impeller, the types available on the market, and considerations for purchasing one.

Understanding Impellers and Motor Specifications

An impeller is a rotating component of a centrifugal pump that converts rotational energy into kinetic energy. This energy helps to move fluids through the system. The size, shape, and materials of an impeller can significantly impact its performance, efficiency, and, ultimately, its price. When we speak of a 2% hp motor, it implies a specific motor power output, which directly influences the type of impeller suitable for use.

Factors Influencing Price

1. Material Composition

The materials used to manufacture an impeller can vary greatly. Common materials include plastics, stainless steel, bronze, and other alloys. Stainless steel and bronze impellers tend to be more expensive due to their durability and corrosion resistance. In contrast, plastic impellers are generally less expensive but may not perform as well under high-pressure conditions.

2. Design Complexity

The design of the impeller can also affect pricing. Simple designs with few blades are typically cheaper as they are easier and less expensive to manufacture. Conversely, intricate designs that optimize fluid dynamics for efficiency can command a higher price due to the additional engineering and production costs involved.

3. Size and Capacity

The size of the impeller and its capacity for fluid movement will directly correlate with the price. Larger impellers designed for high flow rates will usually be more expensive than smaller ones. Additionally, a 2% hp motor will dictate the maximum size and flow rate of the impeller, impacting the cost based on what is suitable for your application.

2 hp motor impeller price

The brand's reputation and the manufacturer's market position can also play a role in pricing. Renowned brands may charge a premium for their products due to perceived quality and reliability. In contrast, lesser-known manufacturers may offer similar products at a lower cost, which could be an attractive option for cost-sensitive buyers.

5. Market Demand and Supply Chain Factors

The broader market dynamics — including demand for impellers and fluctuations in raw material prices — can significantly impact the pricing of motor impellers. Economic conditions, international trade policies, and global events can all play a role in altering the supply chain, thus affecting overall costs.

Purchasing Considerations

Before purchasing a 2% hp motor impeller, buyers should consider several factors

- Compatibility Ensure the impeller is compatible with the motor and the desired application. Checking specifications is essential for optimal performance.

- Performance Requirements Assess the intended use of the impeller. Will it be used in high-pressure conditions? Is efficiency a priority? Understanding these requirements can narrow down options.

- Budget vs. Value While it might be tempting to opt for the cheapest option available, it is crucial to weigh the long-term value and durability against immediate costs. A slightly more expensive but higher-quality impeller may save money in maintenance and replacements over time.

- Supplier Reputation Engage with reputable suppliers who offer warranties or guarantees on their products, ensuring sufficient post-purchase support.

Conclusion

In summary, pricing of a 2% hp motor impeller can vary widely based on materials, design, size, brand reputation, and market conditions. As with any mechanical component, understanding the factors that influence cost and performance is vital for making an informed purchase. Buyers should carefully evaluate their needs and consider both short-term costs and long-term benefits when selecting an impeller for their motor applications. Investing in the right impeller can lead to enhanced efficiency, reduced operational costs, and improved overall performance in fluid management systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025