Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High-Quality 2 3 8 Pipe Caps for Efficient Piping Solutions

Understanding 2%, 3%, and 8% Pipe Caps A Comprehensive Overview

When it comes to the world of piping and plumbing, the significance of fittings and caps cannot be overstated. Among various fittings used in piping systems, pipe caps play a critical role. They are essential for sealing the ends of pipes, preventing the ingress of dirt and moisture, and providing structural integrity. This article delves into the specifics of 2%, 3%, and 8% pipe caps, their applications, and considerations when selecting the right cap for your project.

What Are Pipe Caps?

Pipe caps are designed to fit securely over the ends of pipes. They serve multiple purposes, including stopping the flow of liquids or gases, protecting pipes from environmental damage, and allowing for easy access during maintenance. Pipe caps come in a variety of sizes, materials, and styles, each suited for different applications.

Understanding Percentages in Pipe Caps

The percentages, such as 2%, 3%, and 8%, often refer to the angle of bevel or the degree of taper at the cap’s edge. This specification is significant in determining how a cap fits onto a pipe, ensuring a secure and leak-proof connection.

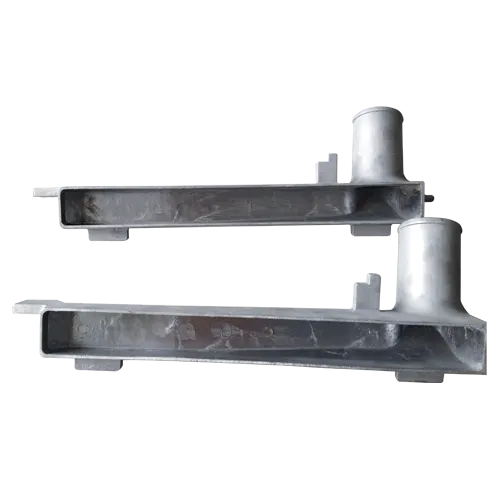

2 3 8 pipe caps

1. 2% Pipe Caps These caps are typically used in scenarios where a minimal slope is required. They are suitable for light-duty applications, where the risk of leakage is lower, and the sealing does not have to be overly robust. Ideal for plumbing systems that don’t experience significant pressure changes, 2% caps offer a cost-effective sealing solution.

2. 3% Pipe Caps These caps provide a bit more support than their 2% counterparts. They are generally used in moderate-pressure situations and can accommodate slight shifts in pipe alignment without compromising the seal. The 3% caps are ideal for irrigation systems or residential plumbing, where integrity is needed but extreme measures are unnecessary.

3. 8% Pipe Caps The 8% caps feature a steeper bevel, making them ideal for high-pressure applications. These caps can withstand significant stress and are designed for industrial settings where pipe integrity is paramount. They are often used in chemical processing plants, oil refineries, and high-demand water systems.

Choosing the Right Pipe Cap

Selecting the appropriate pipe cap is crucial for ensuring the longevity and efficiency of your piping system. Factors to consider include the type of fluid being transported, the pressure within the system, and environmental conditions such as temperature and exposure to chemicals.

In conclusion, understanding the specifications and applications of 2%, 3%, and 8% pipe caps is essential for anyone involved in plumbing or piping projects. Choosing the right cap not only guarantees a secure fit but also enhances the overall reliability of the system, ensuring that it performs efficiently over time.