Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High-Quality 1% 204% Pipe Cap for Effective Pipeline Sealing and Protection

The Importance of 1% and 4% Pipe Caps in Industrial Applications

In the world of industrial plumbing and piping systems, certain components play crucial roles in ensuring that processes run smoothly and efficiently. Among these components, pipe caps—particularly those pertaining to 1% and 4% specifications—deserve special attention. Understanding their significance and applications can greatly enhance the efficiency and safety of any piping system.

What Are Pipe Caps?

Pipe caps are fitting components used to seal the end of a pipe. They come in various sizes, materials, and configurations depending on the type of piping system they are intended for. Common materials include metals such as steel and copper, as well as plastics like PVC and CPVC. The choice of material often depends on the fluid being transported and the environmental conditions it will face.

The Role of 1% and 4% Pipe Caps

The designation of pipe caps as 1% or 4% often pertains to their tolerance levels, dimensions, and pressure ratings. These percentages may not represent direct measurements, but they can indicate the allowable variation in dimensions. For instance, a 1% tolerance allows for less variation compared to a 4% tolerance, making it a more precise choice for applications requiring stricter adherence to specifications.

1% Pipe Caps

1% pipe caps are typically utilized in high-precision industries such as pharmaceuticals, food processing, and aerospace, where even the slightest deviation can result in catastrophic failures or contamination. Their tight tolerance ensures that the sealing surface makes optimal contact, thus preventing leaks and ensuring the integrity of the system.

In these sectors, stringent regulations govern cleanliness and performance. Using 1% pipe caps helps manufacturers comply with these standards, as they contribute to maintaining the purity of the product being processed or transported. Moreover, the reliability offered by these caps can minimize downtime, as fewer leaks mean less maintenance and repair work.

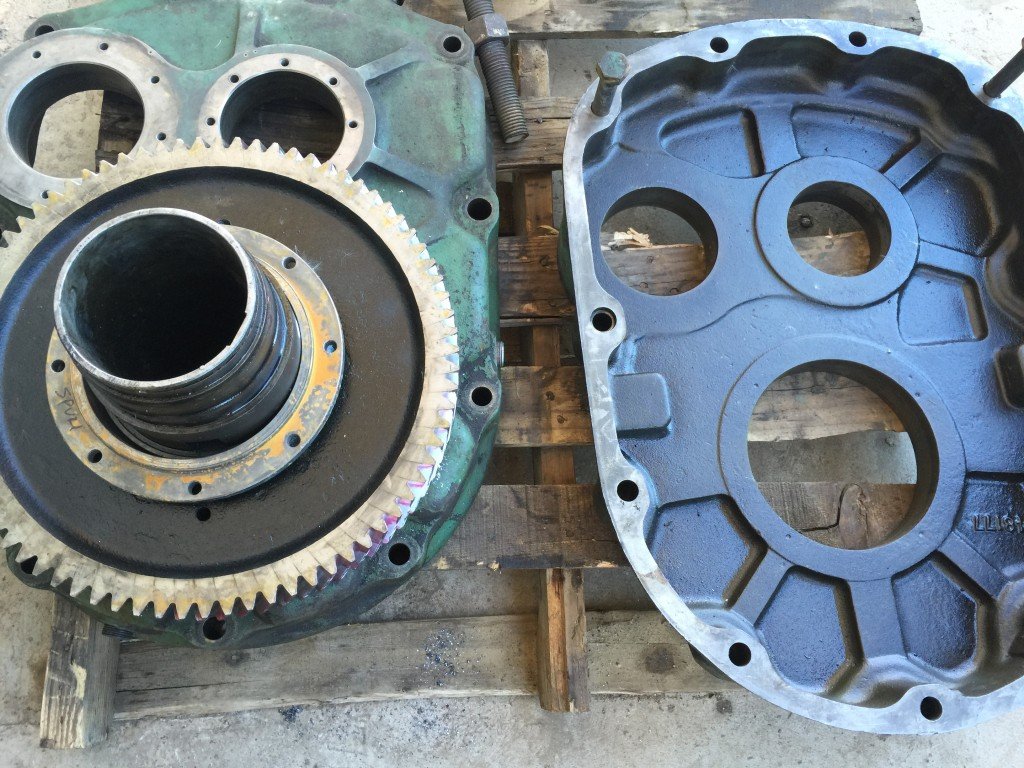

1 4 pipe cap

4% Pipe Caps

In contrast, 4% pipe caps are often used in less sensitive applications, where slight variations may be permissible. These caps find applications in construction, HVAC systems, and general plumbing. While still providing adequate sealing, the looser tolerances allow for easier installation and may also reduce costs.

The versatility of 4% caps makes them ideal for projects that do not demand the same rigorous standards as those found in high-precision fields. This flexibility can lead to significant cost savings, particularly in large-scale construction projects where multiple fittings are required.

Material Considerations

When selecting between 1% and 4% pipe caps, one must also consider the materials involved. For example, stainless steel caps are favored in corrosive environments due to their resistance to rust and degradation, while PVC caps might be chosen for their lightweight and cost-effective properties in less demanding settings.

Application in Pipeline Systems

The application of 1% and 4% pipe caps is observed across various pipeline systems. In oil and gas applications, pipe caps are used to cap off unused lines or to protect fittings and valves during construction. In water treatment facilities, they are essential for maintenance purposes, allowing for safe shutdowns without contaminating the water supply.

Conclusion

In summary, the role of 1% and 4% pipe caps in piping systems cannot be overstated. While they may appear as small components in the grand architecture of industrial plumbing, their importance is pivotal. While 1% pipe caps provide precision and reliability in high-stakes environments, 4% caps offer a balance between performance and cost-effectiveness in more standard applications. Understanding these options enables engineers and project managers to make informed decisions that enhance the safety, efficiency, and integrity of their systems, ultimately contributing to the overall success of their projects. As industries continue to evolve, the need for effective and reliable piping systems will remain a top priority, underscoring the continued relevance of pipe caps in industrial applications.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025