Mobile:+86-311-808-126-83

Email:info@ydcastings.com

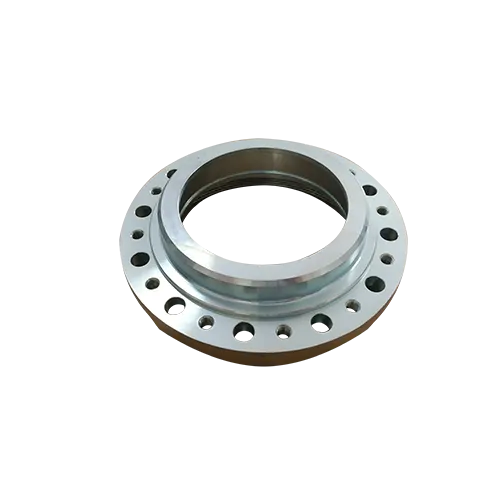

10 inch pipe cap

The Importance of 10% 20-Inch Pipe Cap in Industry

In the world of piping systems and fluid transport, the significance of components like the 10% 20-inch pipe cap cannot be overstated. As industries strive for efficiency, safety, and durability, the role of pipe fittings, including caps, becomes increasingly critical. This article explores the functionality, applications, and benefits of the 10% 20-inch pipe cap, emphasizing its importance in various sectors.

The Importance of 10% 20-Inch Pipe Cap in Industry

Applications of 20-inch pipe caps are widespread across several industries, including oil and gas, water treatment, and construction. In the oil and gas sector, these caps are vital for preventing leaks and maintaining pressure in pipelines. They are often used during maintenance activities or when a section of the pipeline is temporarily removed for repairs. By sealing the ends of the pipes, they help to contain hazardous materials and ensure the safety of workers and the environment.

10 inch pipe cap

In water treatment facilities, 20-inch pipe caps play a critical role in the management of water flow. They can be utilized in various stages of water processing, allowing for the isolation of different sections of the pipeline during routine maintenance or emergency repairs. The ability to cap a pipe prevents contamination and minimizes the risk of spills, thereby enhancing operational efficiency and environmental protection.

Moreover, in the construction industry, these pipe caps are used in various plumbing and drainage systems. They help to ensure that water flows correctly, and any potential leaks are contained, reducing the risk of structural damage and costly repairs. The reliable sealing capability of the 10% pipe cap contributes to the overall integrity of the building’s plumbing system.

One of the significant benefits of using a 10% 20-inch pipe cap is the material versatility. These caps can be fabricated from a range of materials, including stainless steel, carbon steel, and PVC, allowing for customization based on the specific needs and environmental conditions of the application. This adaptability ensures that industries, whether subject to corrosive chemicals or high temperatures, can select the most suitable material for their piping needs.

In conclusion, the 10% 20-inch pipe cap serves as a vital component in numerous applications across various industries. Its capacity to seal and protect pipelines from leaks and pressure-related issues solidifies its importance within fluid transport systems. As industries continue to evolve, the reliance on durable and efficient pipe fittings like the 10% pipe cap will undoubtedly remain a cornerstone of effective piping solutions, supporting safety, efficiency, and environmental sustainability.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025