Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Where Can I Buy Metal? Quality Suppliers & Fast Delivery

This guide covers essential aspects of procuring industrial metals:

- Market trends driving metal procurement

- Technical advantages of modern suppliers

- Supplier comparison analysis

- Custom fabrication capabilities

- Material certification standards

- Aluminum casting case studies

- Optimal sourcing strategies

(where can i buy metal)

Where Can I Buy Metal: Navigating Industrial Procurement Channels

Industrial metal procurement involves multiple channels, each serving distinct needs. Service centers like Ryerson and Reliance Steel supply over 65% of standard mill products including sheet, bar, and structural shapes with typical inventory turnaround under 72 hours. Direct mill sourcing from producers like Nucor and Alcoa offers pricing advantages for orders exceeding 20 tons but requires 6-8 week lead times. According to IBISWorld data, e-procurement platforms now handle 29% of spot purchases under 5 tons through services like MetalSupermarkets and OnlineMetals - particularly beneficial for prototyping needs.

Material Properties and Performance Metrics

Technical specifications dictate procurement decisions. Aerospace-grade aluminum 7075 delivers ultimate tensile strength of 83 ksi compared to structural steel A36 (58-80 ksi) while weighing 165 lb/ft³ versus 490 lb/ft³. Contemporary suppliers increasingly provide enhanced materials like precipitation-hardened stainless steels (yield strength 170-220 ksi) and ultra-conductive copper alloys (100% IACS minimum). Finishing options include MIL-SPEC Type III anodizing (0.002" thickness) and passivation per AMS 2700 for maximum corrosion resistance in demanding applications.

Major Supplier Capability Matrix

| Supplier | Materials Stocked | Cut Tolerance | Minimum Order | Certification |

|---|---|---|---|---|

| Reliance Steel | 1,500+ alloys | ±0.005" | No minimum | ISO 9001, AS9120 |

| Thyssenkrupp | 850+ alloys | ±0.003" | 1 ton | ISO/TS 16949 |

| EMJ Corporation | 600+ alloys | ±0.010" | $500 | ISO 14001 |

| Metal Supermarkets | 250+ alloys | ±0.030" | 1 piece | ASME QMS-1 |

Custom Fabrication Solutions

Leading suppliers offer specialized services beyond standard cut-to-size. Waterjet cutting accommodates materials up to 12" thick with kerf widths as narrow as 0.03". Forge partners provide closed-die impression capabilities producing parts up to 250 lbs. Large service centers maintain dedicated prototyping divisions with 5-axis CNC capacity and coordinate measuring machine (CMM) verification (±0.0005" accuracy). Heat treatment services include solution annealing, cryogenic tempering, and vacuum hardening to meet AMS2750 pyrometry standards.

Compliance and Certification Framework

Material traceability is mandated for critical applications in aerospace (AS9100D), medical (ISO 13485), and defense (DFARS 252.225-7009) sectors. Top-tier suppliers provide mill test reports including chemical composition (ASTM E1479), mechanical properties (ASTM E8/E18), and NDT results. European mills typically supply 3.1/3.2 material certificates compliant with EN 10204:2004. NADCAP-accredited processors maintain comprehensive documentation chains verifying processing parameters at each production stage.

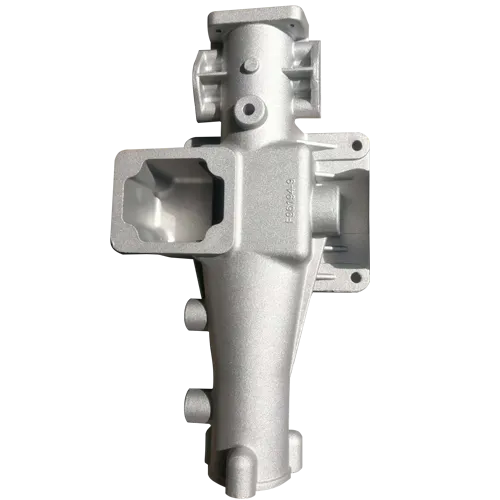

Aluminum Can Casting Production Workflow

A major beverage manufacturer reduced scrap rates by 17% through optimized aluminum sourcing. By implementing certified 3104-H19 canstock sourced from Novelis through Thyssenkrupp Material Services, the plant achieved:

- Consistent 0.267mm blank thickness (±0.002mm variation)

- Hardness uniformity of 58-62 HR30T across coils

- Iron content maintained at 0.6% max for optimal deep drawing

The supplier partnership incorporated statistical process control with 100% spectrochemical verification during production. This reduced stamping tool wear by 23% while maintaining earing characteristics below 3% during cup forming operations.

Strategic Considerations for Where to Buy Metal

Evaluate suppliers on technical capability rather than price per pound alone. Request documented evidence of ISO 17025 testing laboratory accreditation and AS9100 quality management systems. Verify material inventory includes mill-specific designations like Kaiser Select for aerospace alloys or Arconic's proprietary formulations. For critical applications, dual-source arrangements between specialized mills like Constellium for aluminum and Carpenter Technology for superalloys mitigate supply chain vulnerabilities while ensuring material consistency.

(where can i buy metal)

FAQS on where can i buy metal

Where Can I Purchase Metal for DIY Projects?

Q: What are the best places to buy small quantities of metal for home projects?A: Local metal suppliers and hardware stores like Home Depot carry common metals. Online retailers such as OnlineMetals.com offer specialized alloys with doorstep delivery. Scrap yards are cost-effective for bulk or recycled materials.

Where to Source Aluminum for Can Casting?

Q: Which suppliers sell aluminum suitable for DIY can melting and casting?A: Look for aluminum ingots or scrap cans at metal recyclers like MetalSupermarkets. Amazon and eBay also sell small casting-grade ingots. Ensure you select alloys like A356 or 6061 designed for melting.

How to Buy Industrial Metal Quantities?

Q: Where should businesses purchase large volumes of structural steel or aluminum?A: Contact bulk distributors like Ryerson or Reliance Steel. Many offer online quotes and nationwide shipping. Local foundries often supply custom-cut orders for industrial clients.

Can I Use Recycled Soda Cans for Aluminum Casting?

Q: Is recycled beverage can aluminum viable for home casting projects?A: Yes, but expect impurities: Melt multiple cleaned cans in a crucible furnace to remove coatings. The resulting metal has lower strength than pure alloys but works for decorative items. Always use proper ventilation and safety gear.

What Metals Are Sold for Artistic Casting?

Q: Where do artists buy specialized metals like bronze or pewter for sculpture casting?A: Art supply stores like Rio Grande carry jewelry-grade metals. Foundry-specific sites such as BudgetCastingsupply.com offer bronze ingots and casting tools. Local artisan cooperatives often share bulk material sources.