Mobile:+86-311-808-126-83

Email:info@ydcastings.com

what is die casting

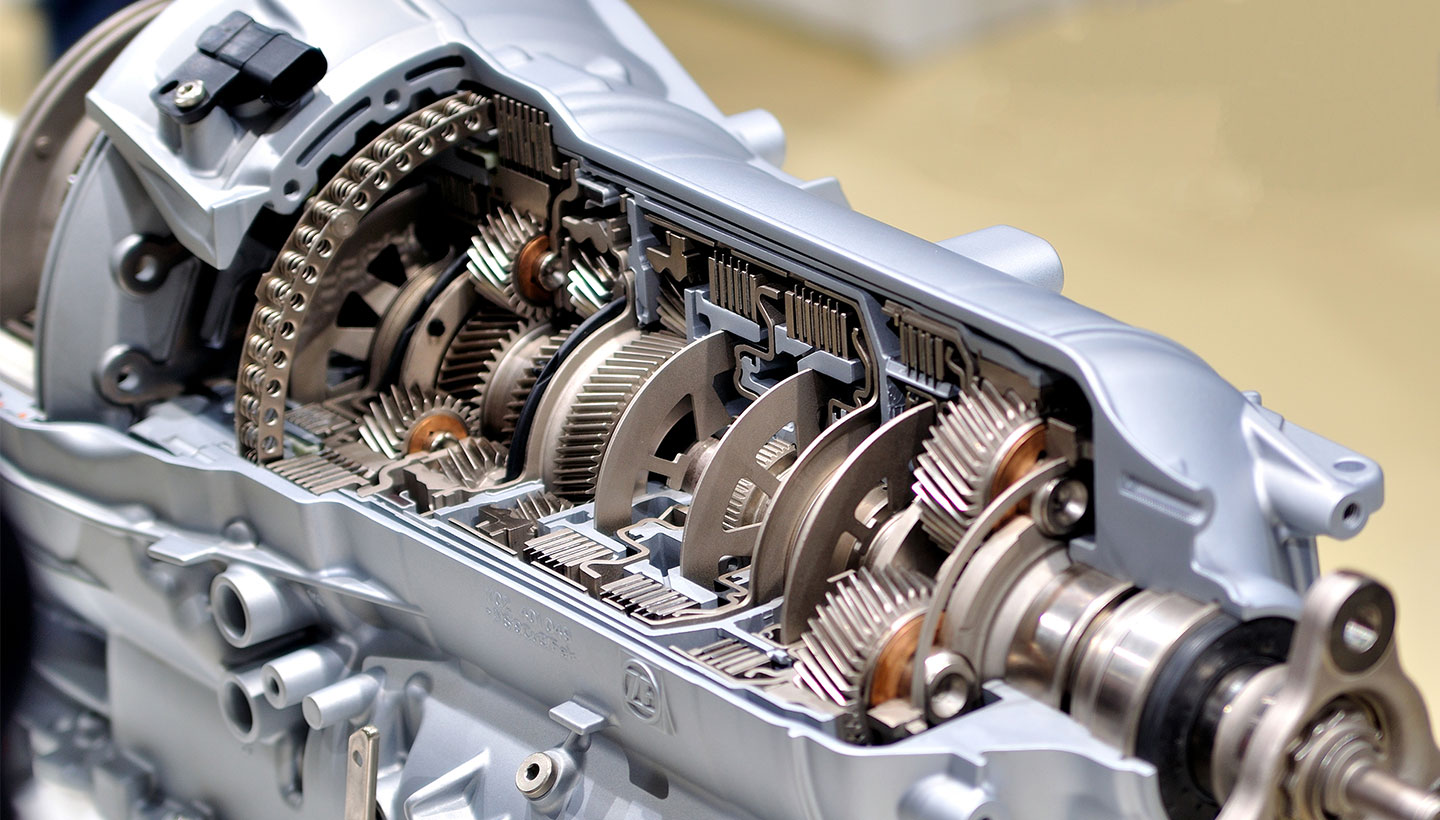

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is widely used for producing complex shapes and components with high precision and excellent surface finishes. Die casting is particularly favored in industries such as automotive, aerospace, and electronics, where the demand for durable and lightweight parts is paramount.

The die casting process starts with the creation of a mold, which is typically made from steel or other durable materials to withstand the high pressures encountered during the casting process. The mold consists of two halves the stationary half, which holds the molten metal, and the moving half, known as the ejector, that releases the finished product once it has cooled and solidified.

.

After the metal has cooled and solidified, the die opens to reveal the finished casting. The next step typically involves trimming away any excess material, known as flash, and other finishing processes such as machining or surface treatment to achieve the desired specifications.

what is die casting

One of the primary advantages of die casting is its ability to produce large quantities of parts with minimal variation, making it highly efficient and cost-effective for mass production. The process also allows for the integration of complex features such as threads and interlocking shapes, reducing the need for additional manufacturing steps. Moreover, die-cast components often exhibit better mechanical properties compared to parts produced by other methods, like sand casting.

However, die casting does come with certain limitations. The initial cost of creating a mold can be high, which may deter its use for low-volume production runs. Additionally, the process is primarily suited for non-ferrous metals, limiting its application for certain industries.

In conclusion, die casting is a pivotal manufacturing technique that enables the production of high-quality, precision-engineered components. Its ability to balance cost, efficiency, and quality makes it an essential choice for many modern industrial applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025