Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 23, 2025 06:00

Back to list

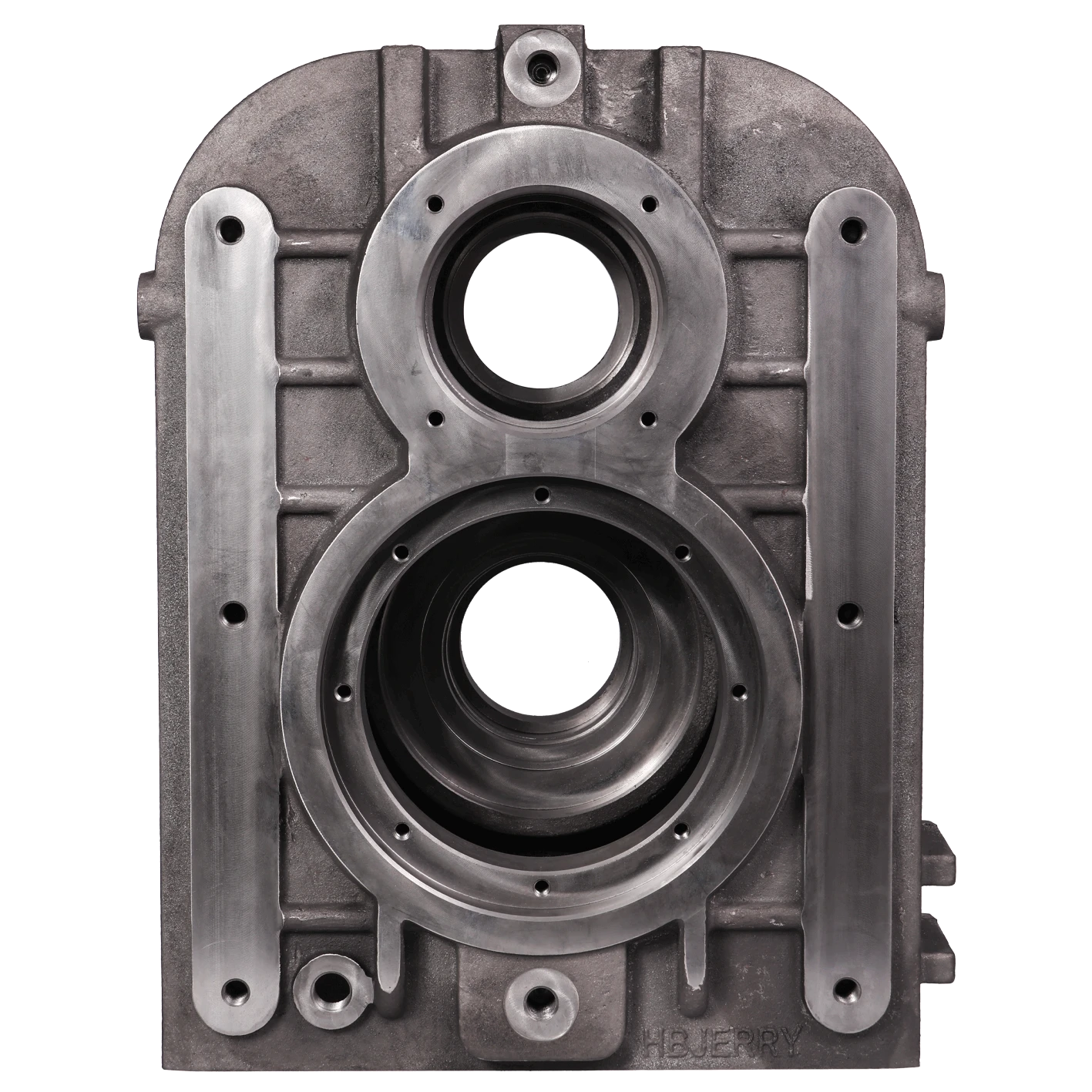

Connector bracket

Water pump impellers are critical components in various systems, from automotive cooling systems to industrial applications and agricultural irrigation. Understanding the different types of water pump impellers, their functions, and the best practices for their use can profoundly impact the efficiency and longevity of the systems they support. This article delves into the world of water pump impellers, offering insights grounded in experience, expertise, authoritativeness, and trustworthiness.

- Cast Iron Durable but prone to corrosion without proper coating, cast iron is a go-to for many standard applications due to its balance of strength and cost-effectiveness. Performance Aspects and Efficiency The efficiency of a pump significantly hinges on the impeller. A well-matched impeller design ensures optimal hydraulic performance, minimizing energy consumption and maximizing output. Precision in engineering and understanding the specific demands of the operating environment can lead to choosing the appropriate type and design, thereby extending the lifespan of the system and reducing operational costs. Innovations and Trends Recent advancements in impeller design focus on improving energy efficiency and accommodating complex fluid mixtures. Computational fluid dynamics (CFD) plays a pivotal role in designing impellers that offer improved flow paths, reducing turbulence and enhancing lifespan. Furthermore, anti-clogging designs are gaining traction, particularly in waste management and mining applications. Best Practices for Selecting Water Pump Impellers 1. Assess Fluid Characteristics Evaluate the type of fluid being pumped, including any solids or variations in viscosity. This assessment determines the type of impeller best suited to avoid clogging or inefficient pumping. 2. Consider Environmental and Operational Factors Analyze the operational environment, such as temperature ranges or exposure to corrosive elements. Material selection based on these factors can enhance longevity and performance. 3. Monitor and Maintain Regular monitoring and maintenance are essential, irrespective of the impeller type. Early detection of wear or imbalance can prevent system failures. Choosing the right type of water pump impeller ensures seamless operation and reliability in applications ranging from industrial to residential settings. By understanding the nuances and capabilities of each type, informed decisions can lead to improved performance, reduced energy costs, and extended equipment life. As water pumping technologies advance, staying informed and adaptable remains key to achieving and maintaining optimum system performance.

- Cast Iron Durable but prone to corrosion without proper coating, cast iron is a go-to for many standard applications due to its balance of strength and cost-effectiveness. Performance Aspects and Efficiency The efficiency of a pump significantly hinges on the impeller. A well-matched impeller design ensures optimal hydraulic performance, minimizing energy consumption and maximizing output. Precision in engineering and understanding the specific demands of the operating environment can lead to choosing the appropriate type and design, thereby extending the lifespan of the system and reducing operational costs. Innovations and Trends Recent advancements in impeller design focus on improving energy efficiency and accommodating complex fluid mixtures. Computational fluid dynamics (CFD) plays a pivotal role in designing impellers that offer improved flow paths, reducing turbulence and enhancing lifespan. Furthermore, anti-clogging designs are gaining traction, particularly in waste management and mining applications. Best Practices for Selecting Water Pump Impellers 1. Assess Fluid Characteristics Evaluate the type of fluid being pumped, including any solids or variations in viscosity. This assessment determines the type of impeller best suited to avoid clogging or inefficient pumping. 2. Consider Environmental and Operational Factors Analyze the operational environment, such as temperature ranges or exposure to corrosive elements. Material selection based on these factors can enhance longevity and performance. 3. Monitor and Maintain Regular monitoring and maintenance are essential, irrespective of the impeller type. Early detection of wear or imbalance can prevent system failures. Choosing the right type of water pump impeller ensures seamless operation and reliability in applications ranging from industrial to residential settings. By understanding the nuances and capabilities of each type, informed decisions can lead to improved performance, reduced energy costs, and extended equipment life. As water pumping technologies advance, staying informed and adaptable remains key to achieving and maintaining optimum system performance.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS