Mobile:+86-311-808-126-83

Email:info@ydcastings.com

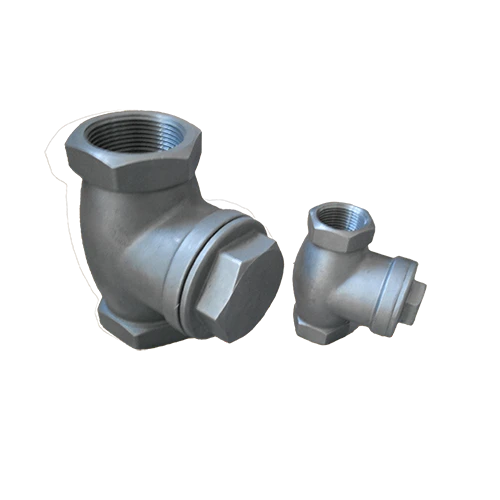

valve

The Fascinating World of Valves A Deep Dive into Their Importance and Applications

Valves are critical components in various systems, playing a central role in controlling the flow of fluids—be it liquids or gases. They are essential in numerous applications, from industrial machinery to everyday household fixtures. In this article, we'll explore the fundamental types of valves, their working principles, and their significance across different sectors.

What is a Valve?

At its core, a valve is a device that regulates, directs, or controls the flow of fluids in a system. This can include processes that involve stopping, diverting, or throttling flow. Valves can be operated manually or automatically, and they come in an array of types tailored to specific functions.

Types of Valves

1. Gate Valves Widely used in applications where the flow is either fully on or fully off, gate valves allow for minimal pressure drop when fully opened. They are not suitable for throttling flow, as they may cause damage to the valve.

2. Globe Valves Designed for regulating flow, globe valves offer a tighter seal than gate valves. They can be used to manage pressure drops and flow rate, making them ideal for applications where precise control is necessary.

3. Ball Valves Known for their reliability and ease of use, ball valves feature a spherical disc to control flow. They are often used in applications requiring quick shut-off and are favored for their durability and low maintenance.

4. Check Valves These valves prevent backflow in a system, ensuring that fluids only flow in one direction. They are crucial in preventing contamination and protecting equipment from potential damage.

5. Butterfly Valves With a rotating disc that regulates flow, butterfly valves are lightweight and allow for quick operation. They are commonly used in large-scale applications such as pipelines.

Operating Principles

Valves can be operated through various mechanisms, including manual handles, pneumatic systems, electric actuators, or hydraulic systems. Manual valves require human intervention to operate, while automated valves can respond to control systems that monitor pressure, temperature, and flow rate. This automation is crucial in improving efficiency and safety in industrial settings.

valve

Applications of Valves

Valves are ubiquitous across a broad spectrum of sectors

- Oil and Gas In the oil and gas industry, valves are essential for controlling the flow of crude oil, natural gas, and refining products. They are critical for maintaining safety and efficiency in pipelines and processing plants.

- Water Management In municipal water systems, valves regulate water distribution, manage pressure levels, and prevent contamination. They are pivotal in ensuring reliable access to clean water.

- Manufacturing and Process Industries Valves control the flow and pressure of raw materials in manufacturing, ensuring efficient production processes. They are indispensable in both chemical manufacturing and food processing, where hygiene and precise control are paramount.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, valves regulate the flow of air and refrigerants, optimizing efficiency and comfort in buildings.

The Future of Valves

As industries advance, the demand for more sophisticated valve technologies is on the rise. Innovations such as smart valves—equipped with sensors and IoT capabilities—are changing the landscape. These devices can provide real-time data on flow rates, pressure, and potential leaks, allowing for predictive maintenance and further enhancing safety and efficiency.

Moreover, the push for sustainability is prompting the development of eco-friendly valve solutions. Manufacturers are focusing on materials and designs that reduce wastage and energy consumption while maintaining high performance.

Conclusion

Valves may often be underrated, but their significance cannot be overstated. From ensuring the smooth operation of vital infrastructures to improving manufacturing processes, these devices are integral to the functionality of countless systems. As technology continues to evolve, the role of valves will only become more complex and vital, affirming their place as unsung heroes in the engineering and industrial landscape.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025