Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Turbo 90 Degree Elbow for Efficient Piping Solutions and Fluid Flow Management

Understanding the Turbo 90 Degree Elbow A Key Component for Efficient Fluid Flow

In the world of piping and plumbing, certain components play crucial roles in ensuring that fluids move efficiently from one point to another. Among these components, the turbo 90 degree elbow stands out due to its unique design and functionality. This article will delve into the characteristics, applications, and benefits of the turbo 90 degree elbow, shedding light on why it is indispensable in various systems.

What is a Turbo 90 Degree Elbow?

A turbo 90 degree elbow is a type of piping fitting that allows a change in direction within a piping system. Unlike standard elbows, the turbo version is specifically designed to minimize turbulence and resist pressure drops, making it ideal for applications where fluid dynamics are critical. Usually made from materials such as stainless steel, PVC, or carbon steel, these elbows are available in different sizes to accommodate various pipe diameters.

Design Features

The design of a turbo 90 degree elbow is characterized by its smooth internal contours. This design reduces the friction that fluids experience when flowing through. Standard 90 degree elbows often exhibit sharp turns which can cause turbulence and lead to energy losses. In contrast, the turbo elbow’s gradual curve significantly decreases the chances of cavitation and allows for a more streamlined flow, resulting in increased efficiency.

Applications

Turbo 90 degree elbows find applications in a variety of industries, including

1. Automotive In turbocharged engines, these elbows are used in the intake and exhaust systems. The efficient flow design helps improve engine performance and fuel efficiency by ensuring that air and exhaust gases move swiftly through the system.

2. HVAC In heating, ventilation, and air conditioning systems, turbo elbows are utilized to facilitate smooth air movement, leading to more efficient heating and cooling cycles and improved overall air quality.

3. Water Treatment In water treatment facilities, the use of turbo 90 degree elbows can enhance flow rates in systems that rely on pumps and filters. This application is critical in maintaining efficient operations and reducing wear and tear on valuable equipment.

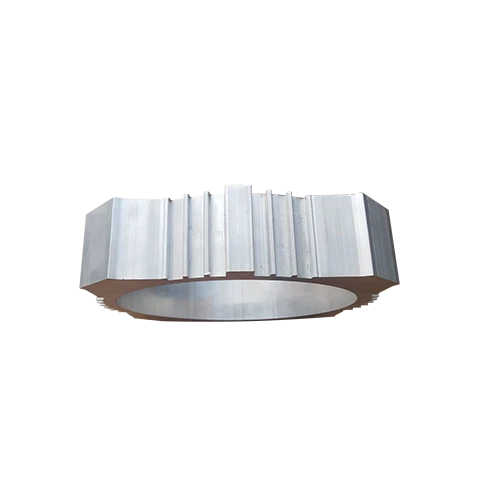

turbo 90 degree elbow

4. Chemical Processing The chemical industry often employs turbo elbows to manage the fluid dynamics of sensitive materials. By minimizing turbulence, these elbows help protect the integrity of chemicals during transport, preventing unwanted reactions or degradation.

Benefits of Using Turbo 90 Degree Elbows

Adopting turbo 90 degree elbows in a piping system offers numerous advantages

1. Reduced Energy Loss By minimizing turbulence, turbo elbows help maintain pressure, which can lead to lower energy costs, especially in large-scale industrial systems where pump efficiency is paramount.

2. Improved Flow Rates The design of turbo elbows promotes steady flow rates, allowing systems to operate more effectively. This improved flow can make a significant difference in applications requiring high precision, such as in manufacturing processes.

3. Enhanced Durability The materials used in turbo elbows are selected for their resistance to corrosion and wear, ensuring a longer operational life. This durability is especially beneficial in harsh environments where traditional fittings may fail prematurely.

4. Cost-Effectiveness While the initial investment in turbo 90 degree elbows may be higher than standard elbows, the long-term savings associated with energy efficiency and reduced maintenance costs often justify the expense.

5. Versatility Turbo elbows are suitable for a wide range of applications and can be customized according to specific needs, making them a versatile choice for engineers and designers.

Conclusion

In conclusion, the turbo 90 degree elbow is more than just a simple fitting; it is a vital component that enhances the efficiency and effectiveness of fluid transport systems across multiple industries. With its innovative design aimed at reducing turbulence and energy loss, it stands as a testament to how engineering solutions can improve operational performance. By understanding the intricacies of the turbo 90 degree elbow, professionals can make informed decisions that lead to better system design, increased efficiency, and long-term cost savings. As industries continue to evolve and demand greater efficiency, components like the turbo elbow will play a crucial role in shaping the future of fluid dynamics.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025