Mobile:+86-311-808-126-83

Email:info@ydcastings.com

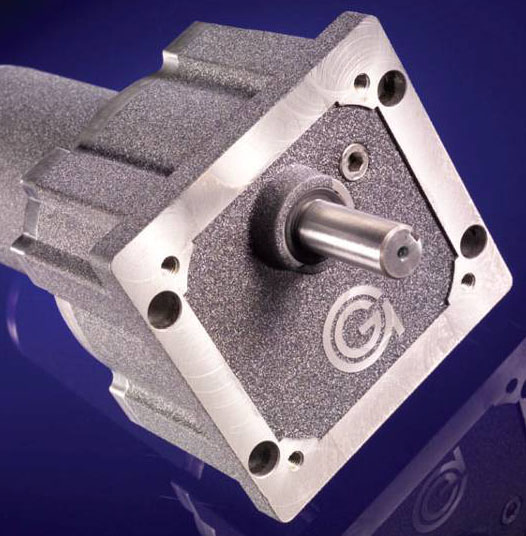

turbine housing

Understanding Turbine Housing A Crucial Component in Turbine Functionality

Turbine housing plays a vital role in the efficient operation of various types of turbines, including gas, steam, and wind turbines. This essential component serves not just as a structural enclosure for the turbine but also significantly influences performance, efficiency, and durability. Understanding the key features and functionalities of turbine housing is imperative for engineers, manufacturers, and maintenance professionals in the energy sector.

Turbine housing, often referred to as the turbine casing, envelops the turbine’s internal components and protects them from external elements such as debris, moisture, and temperature fluctuations. Typically constructed from robust materials such as stainless steel or high-strength alloys, turbine housings are designed to withstand extreme operating conditions, including high temperatures and significant pressure differentials. The selection of material is fundamental, as it must not only provide structural integrity but also resist corrosion and wear over time, extending the lifespan of the turbine and minimizing maintenance needs.

One of the primary purposes of turbine housing is to maintain an optimal environment for the turbine blades. By enclosing the turbine, the housing helps to streamline airflow (in gas and steam turbines) and direct water flow (in hydro turbines) efficiently across the blades. This directly impacts the turbine's performance and efficiency. A well-designed housing can enhance the aerodynamic properties of the turbine, reducing drag and allowing for smoother operation. For wind turbines, the housing also serves to align the rotor and facilitate the conversion of kinetic energy from wind into mechanical energy.

Moreover, turbine housing often incorporates various design features to enhance its functionality. For instance, in gas turbines, the housing may include cooling air passages to manage temperature distribution effectively, ensuring that the components do not overheat and fail. Similarly, skilled engineers will design features that enable easy access for maintenance purposes without compromising the housing's structural integrity during operation.

turbine housing

The turbine housing is also integral to noise and vibration management. As turbines generate significant mechanical vibrations during operation, the housing must be engineered to dampen these vibrations to protect sensitive components and reduce the overall noise pollution associated with turbine operation. Innovations in housing design may include vibration isolation mounts, sound-dampening materials, and advanced computational modeling methods to predict and mitigate vibration impacts.

The integration of sensor technologies into the turbine housing has also revolutionized how turbine operations are monitored. Modern turbine housings can now include condition monitoring systems that analyze parameters like temperature, pressure, and vibration in real time. This data is crucial for predictive maintenance, helping operators identify potential failures before they occur and thereby reducing downtime and repair costs.

In the context of renewable energy, turbine housing significantly impacts the efficiency of wind energy conversion systems. Here, the housing must be aerodynamically optimized not just for performance but also in consideration of noise reduction mechanisms, given that wind turbines are often situated close to residential areas. Design considerations must balance performance with environmental impact, ensuring compliance with regulations while providing maximum energy output.

In conclusion, turbine housing is a multifaceted component that significantly influences the performance, efficiency, and longevity of turbines. From its protective functions to its role in optimizing airflow or fluid dynamics, the housing is an engineering feat that requires careful consideration in its design and material selection. As the demand for sustainable energy increases, continuous innovations in turbine housing design will be essential, contributing to the broader goals of efficiency and environmental stewardship in the energy sector. By understanding and investing in quality turbine housing, manufacturers and operators can ensure that their turbines perform optimally for years to come, meeting the ever-growing energy needs of society.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025