Mobile:+86-311-808-126-83

Email:info@ydcastings.com

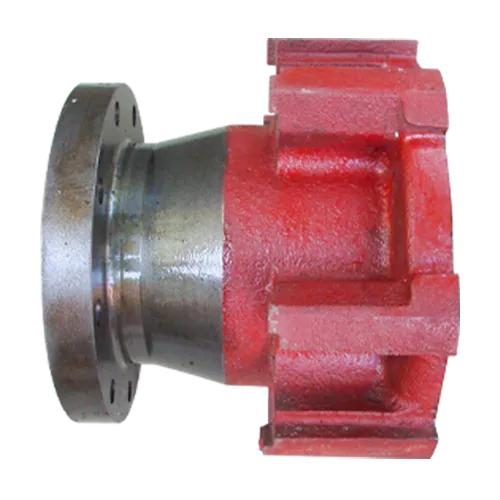

turbine housing

The Importance of Turbine Housing in Modern Engineering

Turbine housing plays a crucial role in various engineering applications, particularly in the aerospace and energy sectors. This specialized component encapsulates the turbine, ensuring safe and efficient operation while allowing for optimal performance. Understanding turbine housing's design, functionality, and impact is vital for engineers and industry professionals.

The Functionality of Turbine Housing

In essence, turbine housing serves multiple purposes. Firstly, it provides structural support for the turbine, holding essential components in place and allowing for the necessary interactions between moving parts. Secondly, it acts as a protective barrier, shielding the turbine from external environmental factors such as debris, moisture, and temperature variations. In high-stakes environments, such as in jet engines or power turbines, this protective role is paramount to maintain efficiency and prevent catastrophic failures.

Design Considerations

The design of turbine housing requires meticulous planning and advanced engineering. Materials used in its construction must balance weight and strength, often leading to the use of specialized alloys that can withstand extreme temperatures and pressures. Additionally, the aerodynamic properties of the housing are critical; a well-designed housing can significantly affect the flow of air or gas, influencing the overall performance of the turbine.

Furthermore, advancements in computational fluid dynamics (CFD) have enabled engineers to simulate airflow within and around the turbine housing, allowing for more informed design choices. This technology helps in identifying potential inefficiencies and optimizing the shape of the housing for maximum airflow, resulting in improved performance metrics.

Importance in Energy Generation

turbine housing

In the energy sector, turbine housing is foundational to both gas and steam turbine systems. In gas turbines, the housing channels high-velocity gas flow from combustion through the turbine blades, converting thermal energy into mechanical energy. In steam turbines, the housing encapsulates the steam flow, guiding it through the blades to generate electricity.

Without an adequately designed turbine housing, the efficiency and safety of these systems would be severely compromised. A malfunction or failure in the housing could lead to significant energy loss, increased operational costs, and, in extreme cases, catastrophic accidents. This underlines the importance of rigorous quality control and testing during the manufacturing process.

Maintenance and Upkeep

Regular maintenance of turbine housing is essential to ensure the longevity and efficiency of the turbine itself. Over time, exposure to high temperatures and pressures can lead to wear and tear, affecting the integrity of the housing. Engineers often use non-destructive testing techniques to assess the condition of the housing without dismantling the turbine. These assessments help identify potential cracks or weak points that could lead to failure if not addressed promptly.

The Future of Turbine Housing

As technology continues to evolve, so too does the design and functionality of turbine housing. Innovations such as 3D printing allow for more intricate designs and structures that were previously impossible to produce. Moreover, integrating smart technologies into turbine housings presents opportunities for real-time monitoring of conditions and performance, enabling predictive maintenance that can further enhance efficiency and safety.

In conclusion, turbine housing is a critical component in the engineering landscape. Its design, functionality, and maintenance are pivotal in ensuring the performance of turbines across various applications. As industries increasingly focus on efficiency and sustainability, the evolution of turbine housing technology will undoubtedly play a significant role in the future of energy generation and aerospace engineering. Understanding its complexities will empower engineers to innovate and improve the systems that rely on this essential component.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025