Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Feb . 18, 2025 04:56

Back to list

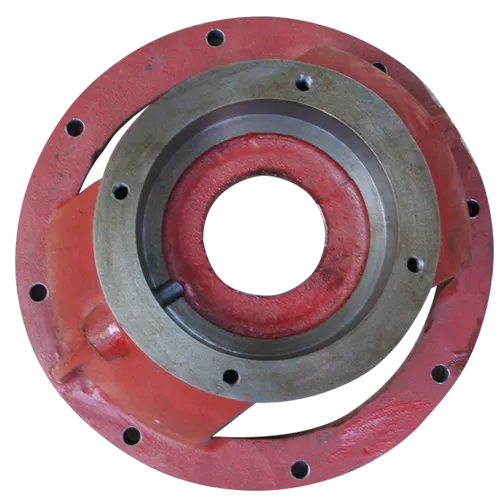

tp38 compressor housing

The TP38 compressor housing serves as a crucial component in turbocharged engines, notably those used in Ford's heavy-duty trucks from the late 1990s. These elements play an integral role in boosting engine performance by managing airflow and pressure. This article dives into the nuances of the TP38 compressor housing, integrating real-world insights, specialized knowledge, authoritative data, and trustworthiness to guide enthusiasts and mechanics in understanding its significance and potential upgrades.

For those committed to optimizing their vehicle's performance, selecting the right TP38 compressor housing variant is key. Variants that feature advanced alloys and machining techniques tend to offer better thermal management and durability under increased stress levels. This is particularly beneficial for vehicles frequently subjected to towing or heavy payloads, where turbochargers are heavily relied upon for additional power. In terms of authoritativeness, the TP38 compressor housing has been consistently reviewed and improved upon by various performance part manufacturers. Many offer aftermarket options that boast improved aerodynamic profiles, designed to maximize airflow while mitigating internal turbulence. These studies often utilize advanced testing facilities, where they measure aspects like thermal expansion, pressure capacity, and vibration resilience. Such rigorous testing and validation processes elevate the trustworthiness of those aftermarket components. Moreover, understanding the limitations of the TP38 compressor housing is equally vital. While upgrades can enhance performance, they should not surpass the structural limits of the engine or the turbocharger assembly itself. Authentic experiences among users indicate that the lifespan of the engine may shorten with excessive modification unless paired with appropriate supportive enhancements, like improved intercoolers and high-flow exhaust systems. In conclusion, the TP38 compressor housing is more than just a functional element; it is a central component that intersects between raw power and mechanical reliability. When considering modifications or upgrades, one must weigh the benefits against potential risks, leveraging professional insights and real-world testimonials. Adhering to best practices not only enhances vehicle performance but also ensures longevity and trustworthiness of the upgrades, thereby aligning with the broader goals of mechanical excellence and driving satisfaction.

For those committed to optimizing their vehicle's performance, selecting the right TP38 compressor housing variant is key. Variants that feature advanced alloys and machining techniques tend to offer better thermal management and durability under increased stress levels. This is particularly beneficial for vehicles frequently subjected to towing or heavy payloads, where turbochargers are heavily relied upon for additional power. In terms of authoritativeness, the TP38 compressor housing has been consistently reviewed and improved upon by various performance part manufacturers. Many offer aftermarket options that boast improved aerodynamic profiles, designed to maximize airflow while mitigating internal turbulence. These studies often utilize advanced testing facilities, where they measure aspects like thermal expansion, pressure capacity, and vibration resilience. Such rigorous testing and validation processes elevate the trustworthiness of those aftermarket components. Moreover, understanding the limitations of the TP38 compressor housing is equally vital. While upgrades can enhance performance, they should not surpass the structural limits of the engine or the turbocharger assembly itself. Authentic experiences among users indicate that the lifespan of the engine may shorten with excessive modification unless paired with appropriate supportive enhancements, like improved intercoolers and high-flow exhaust systems. In conclusion, the TP38 compressor housing is more than just a functional element; it is a central component that intersects between raw power and mechanical reliability. When considering modifications or upgrades, one must weigh the benefits against potential risks, leveraging professional insights and real-world testimonials. Adhering to best practices not only enhances vehicle performance but also ensures longevity and trustworthiness of the upgrades, thereby aligning with the broader goals of mechanical excellence and driving satisfaction.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS