Mobile:+86-311-808-126-83

Email:info@ydcastings.com

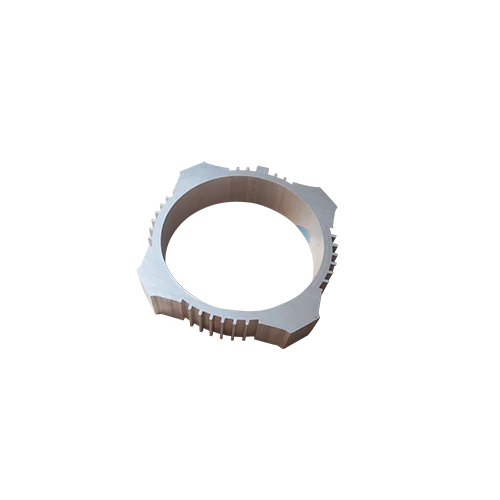

Understanding the Function and Design of Suction Impellers in Fluid Dynamics Applications

Understanding Suction Impellers A Key Component in Fluid Dynamics

Suction impellers play a crucial role in various fluid transport systems, particularly in pumps and turbines. These specialized components are designed to facilitate the efficient movement of liquids, slurries, and gases, making them essential in numerous industries, from water treatment to petrochemical processing.

At its core, a suction impeller is a rotating device that converts mechanical energy into hydraulic energy. The design of the impeller is pivotal, as it directly affects the flow characteristics and efficiency of the system. Typically, suction impellers have blades angled backward, which helps in drawing fluid into the pump. This shape is not only effective for liquid movement but also minimizes the risk of cavitation, a phenomenon where vapor bubbles form and collapse within the fluid, potentially causing damage to the impeller and degrading performance.

One of the key advantages of suction impellers is their ability to handle varying fluid viscosities and solid content. This versatility is particularly valuable in industrial applications where the materials being pumped can change frequently. By selecting the appropriate impeller design and size, engineers can ensure that the system operates efficiently under a wide range of conditions.

suction impeller

Moreover, suction impellers can be configured in different ways to optimize performance for specific applications

. For instance, open impellers are used in applications where the fluid contains solids or particles, while closed impellers are chosen for clear fluids, providing higher efficiency and pressure characteristics. The choice between these configurations will depend on the specific requirements of the operation, such as flow rate, pressure, and the nature of the fluid.In addition to their mechanical attributes, suction impellers also benefit from advancements in materials and technology. Modern impellers can be constructed from high-performance alloys and composites that enhance durability and resistance to corrosion and wear. Such innovations not only extend the life of the impeller but also reduce maintenance costs and downtime.

To ensure optimal performance, regular maintenance and performance monitoring of suction impellers are essential. This can include checking for wear and tear, ensuring proper alignment, and monitoring the pump's operational parameters. A proactive maintenance strategy can significantly enhance efficiency and prolong the lifespan of the impellers.

In conclusion, suction impellers are vital to the functionality of many fluid transport systems. Their innovative designs, adaptability to different mediums, and continuous improvements in materials make them a cornerstone in engineering applications. Whether in municipal water systems, industrial processes, or power generation, the importance of suction impellers cannot be overstated. Understanding their operation and maintenance is crucial for engineers and technicians aiming to maximize efficiency and reliability in their systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025