Mobile:+86-311-808-126-83

Email:info@ydcastings.com

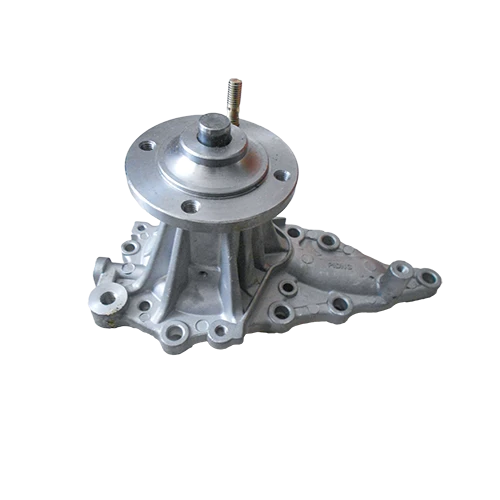

suction impeller

Understanding Suction Impellers Design, Function, and Applications

In the world of fluid mechanics and pump engineering, suction impellers play a crucial role in the efficient movement of liquids. These components are integral to the operation of various types of centrifugal pumps, designed specifically to facilitate the flow of fluids from a lower pressure area into the pump's working chamber. This article delves into the design, functionality, and applications of suction impellers, shedding light on their significance in various industries.

What is a Suction Impeller?

A suction impeller is a rotating component that consists of curved blades arranged around a central hub. When the impeller rotates, it imparts kinetic energy to the fluid, accelerating it and creating a low-pressure zone at the center. This pressure differential draws fluid into the pump's inlet, hence the term suction. The design of the impeller is pivotal, as it directly impacts the pump's efficiency and performance.

Design Considerations

The design of a suction impeller is influenced by various factors, including the type of fluid being pumped, the desired flow rate, and the specific applications it is intended for. Typically, suction impellers are crafted from materials such as stainless steel, bronze, or thermoplastic, chosen for their corrosion resistance and durability.

The blade profile is another critical design aspect. Impellers are typically categorized into two types open and enclosed. Open impellers consist of blades without a shroud, allowing for easy passage of solids. They are advantageous for applications involving slurries or fluids with suspended solids. On the other hand, enclosed impellers have a shroud covering the blades, providing better efficiency and flow control, making them suitable for clean liquids.

Functionality and Efficiency

suction impeller

Suction impellers operate on the principle of centripetal force. As the impeller spins, it forces liquid outward through the blades, increasing its velocity. Once the fluid exits the impeller, a diffuser or volute chamber slows it down, converting kinetic energy into pressure energy. This process results in an increase in pressure, allowing the fluid to be transported through pipelines or systems.

The efficiency of a suction impeller is determined by several parameters, including impeller diameter, rotational speed, and blade angle. Engineers often use computational fluid dynamics (CFD) software to simulate flow patterns and optimize the impeller design. The goal is to maximize hydraulic efficiency while minimizing energy loss due to turbulence or cavitation—a phenomenon where vapor bubbles form in a liquid due to rapid pressure changes, potentially damaging the pump.

Applications of Suction Impellers

Suction impellers are used across a myriad of industries. In the water treatment sector, they facilitate the movement of wastewater through treatment plants, ensuring effective filtration and purification processes. In chemical processing, suction impellers help transport reactive fluids. Their importance extends to the agricultural sector, where they are integral to irrigation systems, ensuring adequate water supply for crops.

Moreover, suction impellers are essential in the HVAC industry, moving refrigerants and cooling water through systems to regulate indoor climates. In the oil and gas sector, they are employed in various applications, including the transfer of crude oil and petrochemicals.

Conclusion

Suction impellers are fundamental components in centrifugal pumps, enabling the effective transfer of fluids across different industries. Their design and functionality are paramount to ensuring efficient operation and longevity of pumping systems. As industries continue to evolve, advancements in materials and design technology promise to enhance the performance of suction impellers, further solidifying their role in fluid dynamics. Whether in municipal water systems, industrial settings, or agricultural applications, the importance of suction impellers cannot be overstated, making them a cornerstone of modern fluid management systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025