Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Feb . 15, 2025 13:14

Back to list

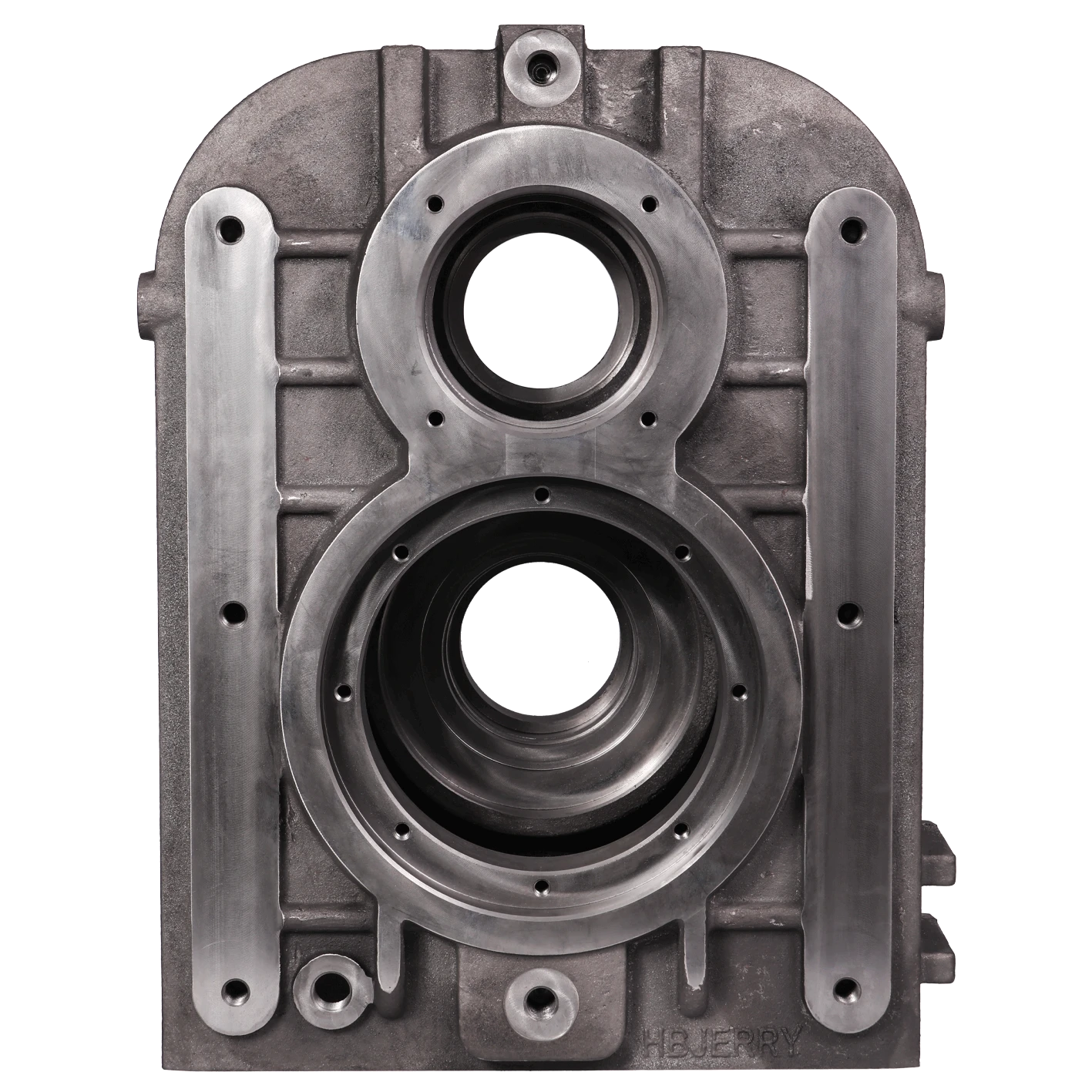

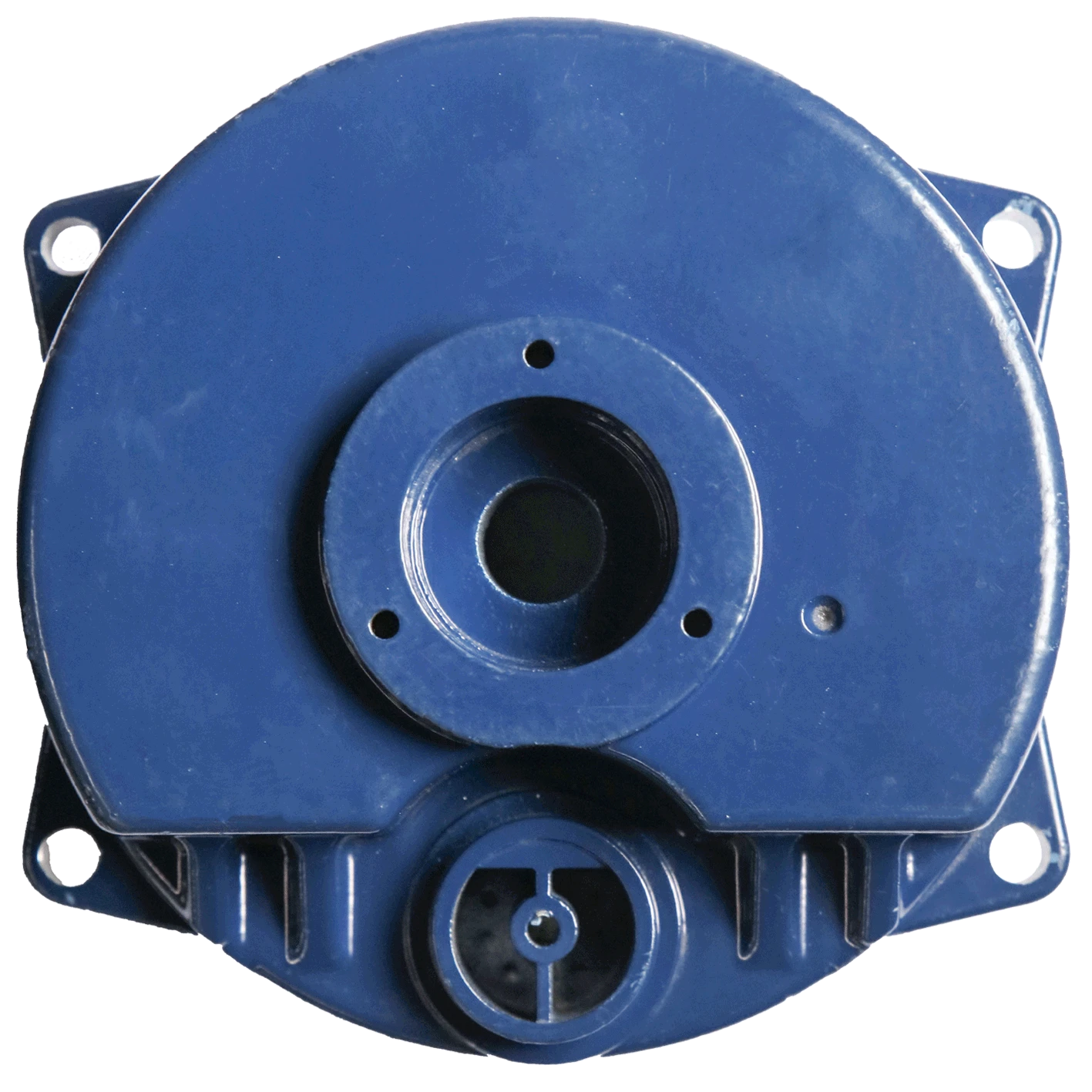

motor housing

The stainless steel turbine housing stands as an integral advancement in the broader turbocharger industry, lauded for its robust performance and reliability. Unlike its cast iron counterparts, stainless steel turbine housing offers unparalleled resistance to corrosion and exceptional durability, making it a material of choice for automotive and industrial applications. Observations and insights from industry veterans reveal that this material addresses various practical challenges faced by engineers and developers alike.

Furthermore, stainless steel's lightweight properties compared to traditional materials can contribute to a reduction in the overall weight of the engine. This weight reduction is an asset in both automotive and industrial applications, where efficiency and performance are paramount. Industry specialists highlight that this feature is particularly beneficial in aviation and maritime sectors, where the power-to-weight ratio is a crucial determinant of performance efficacy. A testament to the authority of stainless steel turbine housing in turbocharger manufacturing lies in its widespread endorsement by recognized engineering firms and turbocharger manufacturers. These organizations trust stainless steel due to its proven track record of delivering reliability and optimal performance. Case studies from leading manufacturers indicate that vehicles equipped with stainless steel turbine housings experience fewer mechanical failures and perform consistently throughout their operational lifespan. The trustworthiness of stainless steel as a material choice is underpinned by extensive testing and real-world application feedback. Leading laboratories and testing facilities subject these turbine housings to rigorous thermal and dynamic stress tests to validate their performance against stringent industry standards. Consequently, this material has earned certifications and endorsements from influential bodies within the automotive and industrial manufacturing sectors. In conclusion, stainless steel turbine housings represent a significant leap forward in turbocharger design and application. Combining unmatched heat resistance, superior corrosion protection, and lightweight strength, they deliver enhanced performance and cost-efficiency across multiple industries. Automotive and mechanical engineers worldwide recognize the expertise and precision embedded in stainless steel turbine housing design, further solidifying its status as a trusted and authoritative material in high-performance machinery contexts. As industries continue to pursue sustainability and efficiency, stainless steel remains at the frontier of innovation, driving forward the standards of turbocharger engineering and application.

Furthermore, stainless steel's lightweight properties compared to traditional materials can contribute to a reduction in the overall weight of the engine. This weight reduction is an asset in both automotive and industrial applications, where efficiency and performance are paramount. Industry specialists highlight that this feature is particularly beneficial in aviation and maritime sectors, where the power-to-weight ratio is a crucial determinant of performance efficacy. A testament to the authority of stainless steel turbine housing in turbocharger manufacturing lies in its widespread endorsement by recognized engineering firms and turbocharger manufacturers. These organizations trust stainless steel due to its proven track record of delivering reliability and optimal performance. Case studies from leading manufacturers indicate that vehicles equipped with stainless steel turbine housings experience fewer mechanical failures and perform consistently throughout their operational lifespan. The trustworthiness of stainless steel as a material choice is underpinned by extensive testing and real-world application feedback. Leading laboratories and testing facilities subject these turbine housings to rigorous thermal and dynamic stress tests to validate their performance against stringent industry standards. Consequently, this material has earned certifications and endorsements from influential bodies within the automotive and industrial manufacturing sectors. In conclusion, stainless steel turbine housings represent a significant leap forward in turbocharger design and application. Combining unmatched heat resistance, superior corrosion protection, and lightweight strength, they deliver enhanced performance and cost-efficiency across multiple industries. Automotive and mechanical engineers worldwide recognize the expertise and precision embedded in stainless steel turbine housing design, further solidifying its status as a trusted and authoritative material in high-performance machinery contexts. As industries continue to pursue sustainability and efficiency, stainless steel remains at the frontier of innovation, driving forward the standards of turbocharger engineering and application.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS