Mobile:+86-311-808-126-83

Email:info@ydcastings.com

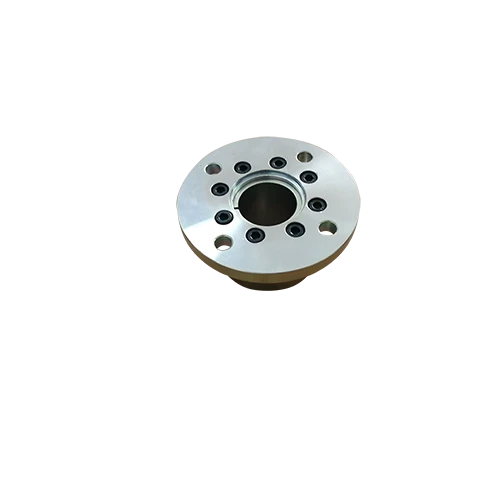

stainless steel casting price per kg

The Cost of Stainless Steel Casting Price Per Kilogram

Stainless steel casting has become an essential process in various industries such as automotive, aerospace, medical, and construction. The demand for components made from stainless steel is on the rise due to their durability, resistance to corrosion, and aesthetic appeal. Consequently, understanding the price per kilogram of stainless steel casting is crucial for manufacturers and consumers alike.

Factors Influencing Stainless Steel Casting Prices

The price per kilogram of stainless steel castings is influenced by multiple factors

1. Material Composition Stainless steel alloys come in various grades, each with different properties and costs. For example, 304 stainless steel, which is commonly used, generally costs less than 316 stainless steel due to the latter's enhanced corrosion resistance properties attributed to the presence of molybdenum. The choice of alloy directly impacts the price per kg, as premium materials tend to be more expensive.

2. Market Demand and Supply The global market for stainless steel is subject to fluctuations based on demand and supply dynamics. When demand for stainless steel increases, such as during construction booms or industrial expansions, prices may rise. Conversely, during economic downturns, excess supply may drive prices down.

3. Casting Process Different methods of casting—such as sand casting, investment casting, or die casting—can affect the overall cost. Investment casting, known for its precision and ability to create complex shapes, typically incurs higher production costs, thereby reflecting a higher price per kg in the final product.

4. Labor Costs Labor costs in different regions can significantly affect the price of stainless steel castings. In regions where manufacturing labor is expensive, the price per kg is likely to be higher. Moreover, skilled labor is often required to work with stainless steel, particularly in precision casting processes, further driving up costs.

stainless steel casting price per kg

5. Production Volume The scale of production also plays a vital role in pricing. Larger production runs can achieve economies of scale, reducing the cost per kg. Conversely, low-volume production may result in higher prices due to fixed costs being spread over fewer units.

6. Finishing and Treatment Post-casting treatments, such as surface finishing, heat treating, and machining, can add to the cost. Components that require additional processing to meet specific specifications or standards will incur higher prices. The complexity and quality of the finish desired can significantly impact the overall cost.

Current Market Trends

As of late 2023, the price of stainless steel castings has shown a general upward trend owing to rising raw material costs and increased demand in emerging markets. Prices can range from approximately $3 to $8 per kilogram, depending on the aforementioned factors. The ongoing transition toward sustainable manufacturing and green technologies has also begun to influence pricing, with companies investing in eco-friendly processes potentially passing those costs onto consumers.

The Importance of Quality and Supplier Choice

When considering stainless steel casting prices, it is essential not only to focus on the cost but also on the quality of the castings and the reputation of the suppliers. Poor-quality castings can lead to failures, increased repair costs, and potential safety hazards, thus ultimately resulting in greater expenses over time. Companies should prioritize suppliers with a proven track record of quality control and trustworthiness, even if their prices are slightly higher compared to competitors.

Conclusion

Understanding the price per kilogram of stainless steel casting is vital for manufacturers and consumers as it directly impacts production costs and overall project budgets. Various factors—including material composition, market dynamics, casting methods, labor costs, production volume, and finishing requirements—play critical roles in determining these prices. As the market continues to evolve, staying informed about trends and supplier options will help stakeholders make better purchasing decisions. An investment in high-quality stainless steel castings can pay dividends in performance and reliability in the long run, making it an essential consideration for any project involving this durable material.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025