Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Casting Strategies for Successful SS Production in Competitive Markets

The Art and Science of SS Casting A Comprehensive Overview

Stainless steel (SS) casting has emerged as a vital process in modern manufacturing, offering a blend of durability, corrosion resistance, and aesthetic appeal. This versatile technique transforms molten stainless steel into shapes and components that serve a multitude of industries, from automotive to aerospace, and from medical to construction. By understanding the intricacies of SS casting, one can appreciate its significance and the innovations surrounding it.

The Art and Science of SS Casting A Comprehensive Overview

The casting process can be broadly classified into two categories sand casting and investment casting. Sand casting is one of the oldest and most widely used methods, involving the creation of a mold from sand, which is then filled with the molten metal. This method is particularly advantageous for large-scale production due to its cost-effectiveness and ability to produce complex geometries.

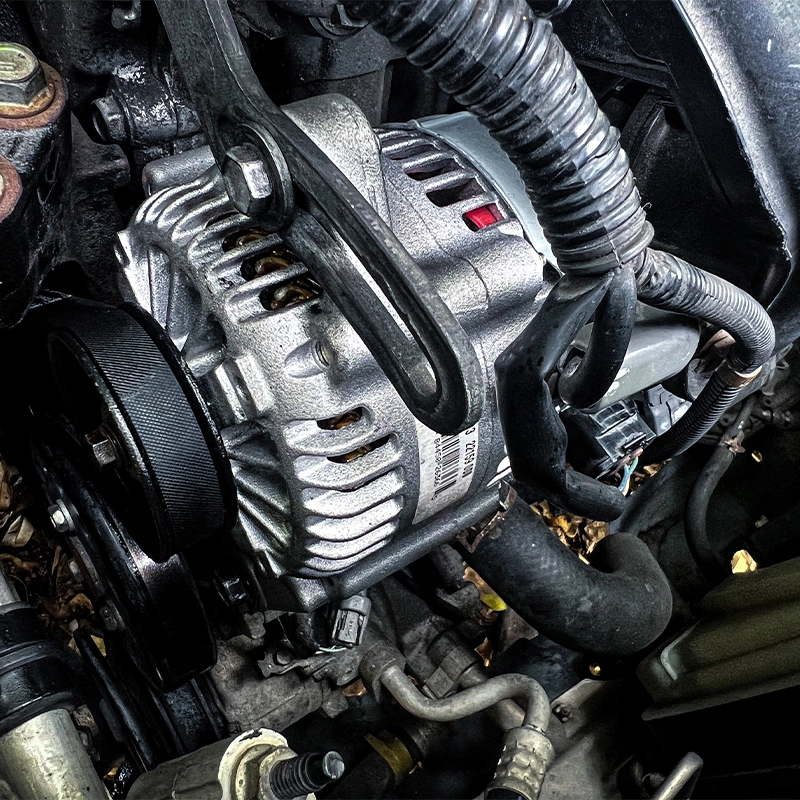

ss casting

On the other hand, investment casting—often referred to as lost-wax casting—allows for greater precision and finer detail. In this technique, a wax model is coated in ceramic material, which is then heated to remove the wax and create a hollow mold for the molten stainless steel. The result is a high-quality finish with minimal post-casting machining, making it ideal for intricate parts that demand tight tolerances.

One of the significant advantages of SS casting is its resistance to corrosion. Stainless steel's high chromium content forms a passive layer of chromium oxide on its surface, which protects the metal from environmental factors that could lead to degradation. This property makes SS castings particularly suitable for applications in harsh conditions, such as chemical processing and marine environments.

However, the process is not without its challenges. Proper temperature control is crucial to avoid defects like porosity or cracking. Additionally, proper design of the mold and gating system is essential to ensure uniform flow and solidification of the molten stainless steel. Continuous advancements in casting technologies, including the use of computer-aided design (CAD) and simulation software, help address these challenges, ultimately improving the quality and efficiency of the casting process.

In conclusion, SS casting is a sophisticated method that underscores the intersection of artistry and engineering. As industries continue to demand more durable and complex components, stainless steel casting will undoubtedly play a pivotal role in meeting those needs while pushing the boundaries of what is possible in manufacturing. Whether through sand casting or investment casting, the future of stainless steel casting looks promising, with endless possibilities for innovation and application.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025