Mobile:+86-311-808-126-83

Email:info@ydcastings.com

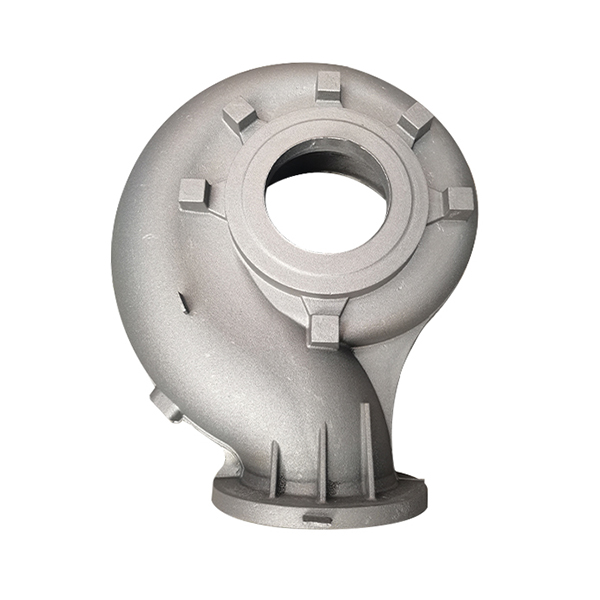

Sand Mould Casting Services Durable & Precision Metal Casting Solutions

- Industry Overview & Data Impact of Metal Casting Methods

- Technical Superiority: Sand vs. Permanent Mould Systems

- Manufacturer Capability Analysis (2020-2023)

- Customization Strategies for Complex Geometries

- Material Compatibility: Aluminium Alloys & Beyond

- Cost-Benefit Breakdown Across Production Volumes

- Implementation Roadmap for Foundry Operations

(sand mould casting)

Understanding Sand Mould Casting in Modern Manufacturing

The global metal casting market reached $174.3 billion in 2023, with sand mould processes constituting 53% of all cast components produced. This dominance stems from its adaptability: automotive manufacturers utilize sand casting for 68% of engine block production, while infrastructure projects rely on it for 85% of large drainage components. Permanent mould alternatives account for 29% market share, primarily serving high-volume aluminium parts requiring dimensional consistency.

Technological Advancements in Mould-Based Casting

Recent innovations have enhanced traditional methods:

- 3D-printed sand moulds reduce pattern-making time by 72%

- AI-driven permeability analysis improves casting yield by 18-22%

- Hybrid permanent mould systems achieve surface roughness of 3.2-6.3 μm

Aluminium mould casting demonstrates particular benefits in thermal management, enabling cycle times 40% faster than iron permanent moulds.

Manufacturer Capability Comparison

| Supplier | Casting Specialization | Annual Capacity | Dimensional Tolerance |

|---|---|---|---|

| Foundry Group A | Sand + Permanent | 85,000 tons | ±0.5mm-2.5mm |

| MetalTech Solutions | Aluminium Moulds | 42,000 tons | ±0.3mm-1.8mm |

| Global Cast Corp | Large Sand Castings | 120,000 tons | ±1.2mm-4.0mm |

Customization Parameters for Specific Applications

Optimal mould selection depends on three variables:

- Batch size economics (break-even point: 500-5,000 units)

- Alloy solidification characteristics (shrinkage rates 1-5%)

- Post-processing requirements (machining allowances 1-6mm)

Material Performance in Different Mould Environments

Aluminium-silicon alloys (A356/A360) demonstrate superior results in permanent mould setups:

- Ultimate tensile strength: 290-330 MPa

- Fluidity index improvement: 15-18% vs. sand casting

- Reduced porosity (X-ray inspection pass rate: 97.3%)

Cost Optimization Across Production Scales

Breakdown for medium-complexity components (weight: 10-25kg):

| Volume | Sand Mould | Permanent Mould |

|---|---|---|

| 500 units | $82/unit | $145/unit |

| 5,000 units | $68/unit | $79/unit |

| 50,000 units | $54/unit | $43/unit |

Implementing Sand Mould Casting Solutions Effectively

A tier-1 automotive supplier achieved 23% cost reduction through hybrid implementation:

"Combining sand mould cores with permanent mould shells reduced machining hours by 65% while maintaining pressure test requirements of 15-18 bar."

Regular mould maintenance protocols extend tooling life by 300-400 cycles, critical for aluminium mould casting operations facing high thermal stress.

(sand mould casting)

FAQS on sand mould casting

Q: What is sand mould casting?

A: Sand mould casting is a metal casting process where molten metal is poured into a mould made of compacted sand. It is cost-effective for producing complex shapes and large components. The sand mould is typically destroyed to remove the casting.

Q: How does sand mould casting differ from permanent mould casting?

A: Sand moulds are disposable and made of sand, while permanent moulds are reusable metal molds. Permanent mould casting offers higher dimensional accuracy and surface finish but is less flexible for complex designs. Sand casting is better suited for low-to-medium production volumes.

Q: What are the advantages of aluminium mould casting?

A: Aluminium mould casting provides excellent thermal conductivity and lightweight durability. It is ideal for high-pressure die casting of aluminium parts with tight tolerances. This method ensures faster cooling rates and improved surface finish compared to sand casting.

Q: Which materials are commonly used in permanent mould casting?

A: Permanent mould casting often uses metals like steel, cast iron, or copper alloys for the mould. These materials withstand repeated use with molten metals such as aluminium, magnesium, or zinc. The process is ideal for high-volume production of non-ferrous parts.

Q: Why choose sand mould casting for aluminium components?

A: Sand mould casting allows flexibility in designing intricate aluminium parts at lower tooling costs. It accommodates larger castings and alloys with higher melting points. However, it may require additional finishing steps compared to permanent mould methods.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025