Mobile:+86-311-808-126-83

Email:info@ydcastings.com

motor impeller price

Understanding the Pricing of Motor Impellers Factors and Trends

In the ever-evolving world of industrial machinery, motor impellers play a critical role in various applications, from water management systems to air conditioning units. As essential components that facilitate fluid movement, the pricing of motor impellers has garnered significant attention among manufacturers, engineers, and purchasing managers. This article explores the factors influencing motor impeller prices and the trends shaping the market.

Key Factors Influencing Prices

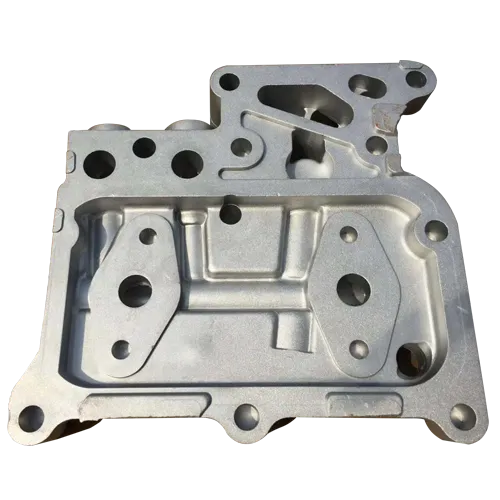

1. Material Composition The material used to manufacture motor impellers significantly affects their price. Common materials include plastics, aluminum, and stainless steel. Each material comes with its own set of properties and costs. For instance, while plastic impellers may be more affordable, they may not offer the same durability as metal alternatives, which can lead to higher long-term costs due to maintenance and replacement needs.

2. Design Complexity The design of the impeller can also impact its cost. More complex designs, which may be required for specific applications or performance enhancements, typically demand higher manufacturing costs. Advanced computational fluid dynamics (CFD) techniques are often employed to optimize impeller designs, which can further increase investment in research and development.

3. Manufacturing Process The method of production is another critical factor. Traditional casting and machining processes might be cheaper, while techniques such as 3D printing may come with a higher upfront cost but can offer advantages in terms of customization and rapid prototyping. The rise of additive manufacturing is changing the landscape of how parts like motor impellers are produced and priced.

4. Supply Chain Dynamics External economic factors play a significant role in pricing. Fluctuations in raw material costs, changes in trade policies, and disruptions in supply chains—such as those experienced during the COVID-19 pandemic—can lead to significant price variability. Manufacturers need to stay agile and adaptive to navigate these challenges.

motor impeller price

5. Market Demand The overall demand for motor impellers in various sectors, including HVAC, automotive, and industrial machinery, influences pricing. As industries grow and evolve, they may require specialized impellers, which can command higher prices due to their tailored features.

Current Market Trends

In recent years, there has been a noticeable shift towards energy-efficient solutions in the manufacturing of motor impellers. Consumers and businesses are increasingly looking for products that not only perform well but also help reduce energy consumption. This trend has led manufacturers to invest in more sophisticated designs and materials, which can initially drive up costs but potentially result in savings over the product's lifecycle.

Moreover, sustainability has become a significant priority, pushing manufacturers to explore eco-friendly materials and production methods. This shift can also influence pricing, as sustainable materials may come at a premium. However, as these practices become more mainstream, costs may decrease through economies of scale.

Conclusion

The pricing of motor impellers is a multifaceted issue influenced by material composition, design complexity, manufacturing processes, supply chain dynamics, and market demand. As industries prioritize efficiency and sustainability, staying informed about these factors is crucial for making informed purchasing decisions. Understanding the nuances of pricing can help businesses optimize their operations and enhance their competitive edge in the market.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025