Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding Metal Casting Processes in Modern Foundries for Enhanced Production Efficiency

The Importance of Metal Casting Foundries

Metal casting is a vital process in the manufacturing industry, providing the foundation for producing a diverse range of metal components and products. At the heart of this process lies the metal casting foundry, a specialized facility dedicated to shaping molten metal into useful objects through various casting techniques. This article delves into the role of foundries, the casting process, and its significance in contemporary manufacturing.

Understanding Metal Casting

Metal casting is an age-old technique that involves pouring molten metal into a mold, where it solidifies to acquire specific shapes and sizes. This process can produce intricate designs that would be challenging or impossible to achieve through other manufacturing methods. Foundries utilize different types of metal, including iron, steel, aluminum, and bronze, each selected based on the application's requirements.

Types of Casting Processes

Foundries employ various casting techniques, each suitable for specific applications

1. Sand Casting This is one of the oldest and most widely used methods, involving a sand mold that can be easily shaped and reused. Sand casting is versatile, capable of producing both small and large components with complex geometries.

2. Die Casting In die casting, molten metal is injected into a metal mold under high pressure. This method is ideal for mass production, providing high precision and smooth surfaces, commonly used for aluminum and zinc components.

3. Investment Casting Also known as lost-wax casting, this method involves creating a wax model, coating it with a ceramic shell, and then melting the wax away. This technique is perfect for intricate designs and produces high-quality parts, often used in aerospace and medical applications.

4. Permanent Mold Casting This technique utilizes reusable molds made of metal, offering improved dimensional accuracy and surface finish. It's suitable for producing large quantities of similar parts.

The Role of Foundries

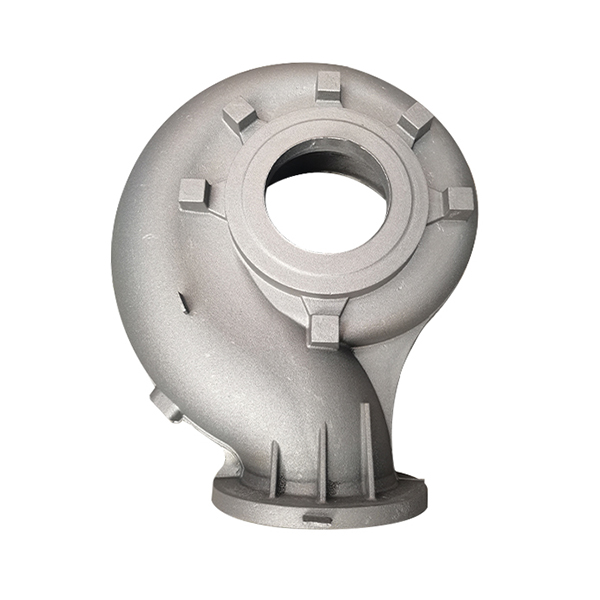

metal casting foundry

Foundries serve several critical functions in manufacturing

- Prototype Development Foundries enable the creation of prototypes quickly, allowing manufacturers to test designs and modifications before mass production.

- Material Utilization Foundry operations can recycle scrap metal, reducing waste and promoting sustainability. This practice helps align with global environmental standards and fosters resource conservation.

- Diverse Applications Foundries cater to various industries, including automotive, aerospace, construction, and art, producing everything from engine blocks to sculptures. This adaptability underscores the significance of foundries in modern industrial practices.

Quality Control and Innovations

Maintaining quality is paramount in foundry operations. Advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining have significantly enhanced precision and efficiency in the casting process. Moreover, foundries increasingly employ non-destructive testing methods, such as ultrasonic testing and X-ray inspection, to ensure the structural integrity of cast products.

Innovations in materials science have also introduced new alloys and composites that enhance the properties of cast metal parts, improving strength, corrosion resistance, and weight reduction. The emergence of additive manufacturing, or 3D printing, is transforming foundry practices by allowing the creation of molds and cores with intricate designs that were previously unattainable.

Conclusion

Metal casting foundries are indispensable in the manufacturing landscape, providing the necessary infrastructure to produce a wide array of components essential for various industries. As technology continues to advance, foundries are evolving, incorporating innovative techniques to enhance production quality and efficiency. The importance of these facilities extends beyond mere manufacturing; they play a crucial role in resource conservation, prototype development, and the customization of products to meet the ever-changing demands of the market.

In an era of rapid technological advancement, the future of metal casting foundries appears promising, driven by the need for quality, sustainability, and innovation. As industries continue to grow and evolve, foundries will remain pivotal in supporting this progress, shaping a better tomorrow through metal casting.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025