Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Low Pressure Die Casting - Precision Metal Casting Solutions

Understanding Low Pressure Die Casting

Low pressure die casting is a widely used manufacturing process that allows for the production of high-quality metal components with excellent dimensional accuracy and surface finish. This method is particularly favored in the automotive, aerospace, and consumer goods industries due to its efficiency and cost-effectiveness. In this article, we will explore the fundamentals of low pressure die casting, its benefits, applications, and considerations for successful implementation.

What is Low Pressure Die Casting?

Low pressure die casting is a process in which molten metal is poured into a die under low pressure, typically between 0.02 to 0.5 MPa. This low-pressure application helps to ensure that the molten metal flows smoothly into the mold cavity, reducing the risk of turbulence and air entrapment. Unlike high-pressure die casting, which uses more intense pressures, low pressure die casting operates under a gentler method, allowing for greater complexity in the components produced.

Process Overview

The low pressure die casting process begins by heating the metal until it reaches a molten state, typically in a furnace. The molten metal is then transferred into a holding chamber connected to the die. Air within the die is displaced as the metal is pushed into the cavity, creating a vacuum that facilitates the filling process. The metal solidifies as it cools within the die, after which the die is opened, and the cast part is ejected.

Advantages of Low Pressure Die Casting

One of the primary advantages of low pressure die casting is its ability to produce parts with thinner walls and complex geometries. This method is also highly efficient, as it maximizes material usage and minimizes waste. Moreover, components produced through low pressure die casting exhibit excellent surface quality, reducing the need for extensive secondary processing like machining or polishing.

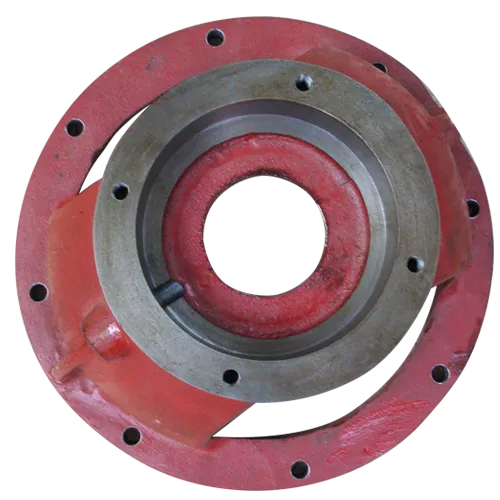

low pressure die casting

Another significant benefit is the process’s ability to handle alloys that are difficult to cast using other methods. The controlled filling and solidifying environment allows for better mechanical properties in the final product, making it suitable for high-performance applications.

Applications

Low pressure die casting finds extensive application in various industries. In the automotive sector, it is used to manufacture engine blocks, transmission housings, and structural components that require high strength and durability. In the aerospace industry, low pressure die casting is utilized for producing lightweight parts that can withstand significant stresses. Additionally, consumer goods such as electronics enclosures often benefit from this manufacturing process due to its efficiency and surface finish.

Considerations for Implementation

While low pressure die casting offers numerous advantages, several factors must be considered for successful implementation. The design of the die is crucial; it must be carefully engineered to accommodate the material flow and cooling rates. Furthermore, the selection of the right alloy is essential to ensure that the final product meets desired mechanical properties and performance standards.

Regular maintenance of the casting equipment and tooling is also necessary to maintain quality and reduce downtime. Finally, skilled operators must oversee the process to handle any issues that may arise during production.

Conclusion

Low pressure die casting is a versatile and efficient method for producing high-quality components across various industries. Its ability to create complex shapes with excellent surface finishes positions it as a vital technology in modern manufacturing. By understanding the nuances of this process, industries can leverage its capabilities to enhance product performance and production efficiency.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025