Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Innovative Stainless Steel Artistry Through Lost Wax Casting Techniques and Applications

Lost Wax Casting of Stainless Steel A Timeless Art

Lost wax casting, also known as investment casting, is an ancient technique that has stood the test of time, adapting to modern materials and technologies. Among the various metals that can be cast using this method, stainless steel has emerged as a popular choice due to its unique properties and aesthetic appeal. This article explores the intricacies of lost wax casting in stainless steel, its benefits, applications, and the process involved.

The Lost Wax Casting Process

The lost wax casting process consists of several distinct steps, each crucial in producing high-quality stainless steel products. It begins with the creation of a wax pattern, which replicates the desired shape of the final product. This pattern is typically made from a high-quality wax that can withstand the subsequent processes.

Once the wax pattern is completed, it is coated with a ceramic shell. This shell is formed by dipping the wax pattern into a slurry made of fine sand and a binding agent, followed by application of dry sand. This process is repeated to build up a thick shell capable of withstanding the casting process.

After the ceramic shell has hardened, the next step is to remove the wax. This is generally achieved through a process known as dewaxing, where the shell is heated to melt and drain the wax. This leaves behind a hollow cavity in the shape of the desired pattern.

The shell is then preheated to a specific temperature before molten stainless steel is poured into it. The high temperature of the molten metal ensures that it fills every detail of the cavity, capturing intricate designs and features. After the metal has cooled and solidified, the ceramic shell is broken away to reveal the cast stainless steel object.

Advantages of Stainless Steel in Lost Wax Casting

lost wax casting stainless steel

Stainless steel offers several advantages that make it an ideal material for lost wax casting. First and foremost, its resistance to corrosion and staining makes it suitable for a wide range of applications, particularly in environments that may expose it to moisture or chemicals. This property is especially beneficial in industries such as medical devices, automotive, and aerospace.

Moreover, stainless steel can achieve a remarkable level of detail, which is crucial for intricate designs often desired in art, jewelry, and high-precision engineering parts. The casting process allows for complex shapes and smooth finishes, reducing the need for extensive machining after casting.

Additionally, stainless steel is known for its strength and durability. Parts cast using this method can withstand considerable stress and strain, making them reliable for demanding applications. This strength-to-weight ratio is particularly advantageous in sectors like aerospace, where every ounce counts.

Applications of Lost Wax Cast Stainless Steel

The versatility of lost wax casting combined with the durability of stainless steel opens up a vast array of applications. In the artistic realm, sculptors often utilize this method to create intricate metal artworks, sculptures, and jewelry. The ability to achieve fine details makes lost wax casting a favored technique among artists.

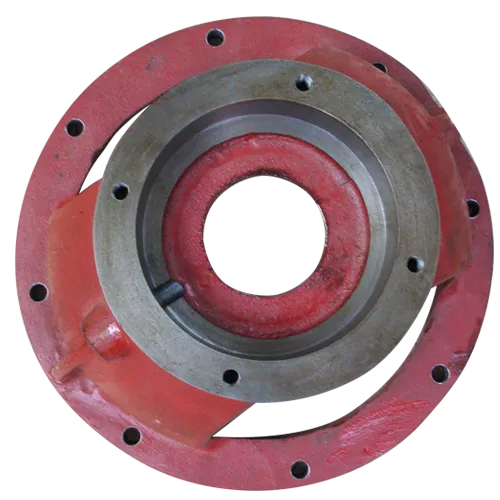

In industrial applications, lost wax casting is employed to produce components like valves, pump housings, and various fittings that require high precision and durability. In the medical field, surgical instruments and implants made from stainless steel benefit significantly from this technique, as hygiene and strength are paramount.

Conclusion

Lost wax casting of stainless steel is a remarkable fusion of ancient craftsmanship and modern engineering. This technique not only preserves the artistry of metalworking but also benefits from the superior properties of stainless steel. With its ability to produce intricately designed, durable, and corrosion-resistant components, lost wax casting continues to be a preferred choice across various industries. As technology progresses, so too does the potential for innovation in lost wax casting, ensuring its relevance for years to come. Whether for art or industry, the timeless allure of this technique remains unmatched.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025