Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Ene . 09, 2025 12:03

Back to list

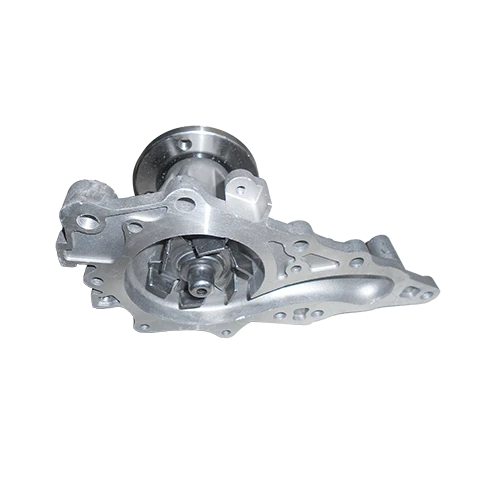

impeller on pump

An impeller within a pump system is a highly engineered component that transforms rotational energy into the flow of fluids. Understanding its design, functionality, and application is crucial to maximizing pump efficiency and longevity. This article provides compelling insights intended to satisfy Google’s search engine optimization while benefiting those in the market to improve their impeller-centric systems.

In enhancing trustworthiness, real-world case studies can be pivotal. Consider the example of a water treatment facility that optimized its pump efficiency by replacing worn-out impellers with custom-designed stainless steel models, resulting in a 15% increase in throughput and a significant reduction in energy consumption. This real-life scenario exemplifies the critical importance of selecting and maintaining impellers, particularly in high-demand environments. The operational stability and efficiency of pumps are heavily reliant upon appropriate maintenance routines. Professionals within the industry recommend regular inspection and dynamic balancing of impellers to prevent premature failures. Symptoms of wear include unusual vibrations, reduced flow rate, and increased energy consumption. Regular diagnostics and preventive measures, backed by expert consultation, ensure the longevity and sustainable performance of pump systems. In conclusion, impellers are at the heart of pump systems, and their impact on performance and reliability cannot be overstated. By focusing on precise design, appropriate material selection, and regular maintenance informed by industry expertise, businesses can significantly enhance their operational efficiency. Choosing impellers aligned with the specific demands of your application not only promotes system reliability but also contributes to cost efficiency, establishing a solid foundation for trusting technology and the expertise of industry leaders.

In enhancing trustworthiness, real-world case studies can be pivotal. Consider the example of a water treatment facility that optimized its pump efficiency by replacing worn-out impellers with custom-designed stainless steel models, resulting in a 15% increase in throughput and a significant reduction in energy consumption. This real-life scenario exemplifies the critical importance of selecting and maintaining impellers, particularly in high-demand environments. The operational stability and efficiency of pumps are heavily reliant upon appropriate maintenance routines. Professionals within the industry recommend regular inspection and dynamic balancing of impellers to prevent premature failures. Symptoms of wear include unusual vibrations, reduced flow rate, and increased energy consumption. Regular diagnostics and preventive measures, backed by expert consultation, ensure the longevity and sustainable performance of pump systems. In conclusion, impellers are at the heart of pump systems, and their impact on performance and reliability cannot be overstated. By focusing on precise design, appropriate material selection, and regular maintenance informed by industry expertise, businesses can significantly enhance their operational efficiency. Choosing impellers aligned with the specific demands of your application not only promotes system reliability but also contributes to cost efficiency, establishing a solid foundation for trusting technology and the expertise of industry leaders.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS