Mobile:+86-311-808-126-83

Email:info@ydcastings.com

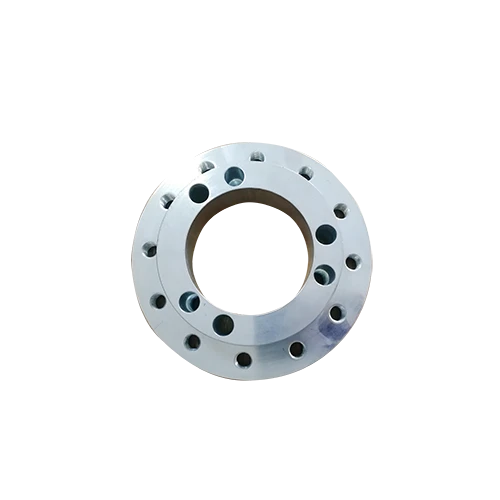

Connector bracket

Impellers are integral components of a pump system, driving the movement of fluids by converting rotational energy into kinetic energy. Understanding the nuances of impeller selection and maintenance can significantly influence pump efficiency and longevity, making it a critical focus for industrial professionals and homeowners alike.

Selecting the right impeller for a pump involves considering several critical factors, ensuring that the pump performs optimally for its intended application. Material composition is paramount; stainless steel impellers, for example, excel in corrosive environments due to their durability and resistance to chemical wear, whereas plastic impellers are often employed in settings requiring lighter, non-corrosive solutions. Matching impeller materials to specific pumping conditions can prevent unexpected failures and extend the pump's operational life.

In addition to material considerations, the design and geometry of the impeller play a crucial role. Common types include closed, semi-open, and open impellers, each offering distinct advantages. Closed impellers are highly effective in clean fluid applications where maximum efficiency is needed, as their design minimizes leakage and maximizes pressure. Conversely, semi-open and open impellers are better suited for handling solids or abrasive materials, given their reduced likelihood of clogging. Selecting the appropriate design based on the fluid characteristics is essential to maintaining steady, reliable pump performance.

Operating conditions further dictate the choice of impeller. The viscosity of the fluid, temperature, pressure requirements, and environmental conditions must all be factored into the decision-making process. High-viscosity fluids necessitate impellers with broader channels and a more robust structure to minimize resistance and maintain flow rates. Similarly, extreme temperatures may require specialized materials that can withstand expansion and contraction without degrading over time.

impeller on pump

Proper maintenance of the impeller is equally crucial. Regular inspection for signs of wear, such as pitting or erosion on the vanes, can prevent catastrophic failures. Scheduled cleaning and lubrication, where appropriate, help maintain the efficiency of the pump and preserve the impeller's integrity. For industries where downtime equates to substantial losses, predictive maintenance strategies using diagnostic tools can foresee potential issues before they escalate, allowing for timely intervention and reducing the risk of unplanned outages.

Expert consultation is invaluable when dealing with complex pump systems. Professionals with deep expertise in fluid dynamics and pump engineering can offer insights that integrate advanced technologies, such as computational fluid dynamics (CFD) simulations. These tools model fluid flow, allowing for precise impeller performance predictions and bespoke modifications to match unique operational demands.

Ultimately, trust in the components that power your pumping system is paramount. Reputable manufacturers provide certifications and adhere to international standards, guaranteeing reliability and performance consistency. Investing in high-quality impellers from trusted sources not only ensures immediate performance but also long-term cost efficiency by reducing repair and replacement expenses.

In conclusion, the impeller's role in a pump's functionality cannot be overstated. Its selection, maintenance, and the expertise of professionals involved contribute to the system's overall performance and longevity. As advancements in materials science and fluid dynamics continue to evolve, staying informed and aligning with authoritative knowledge and trusted practices will ensure that pump systems operate at their peak potential.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025