Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High Quality Castings Precision Aluminum & High Pressure Solutions

- Industry Standards in Precision Manufacturing

- Technical Superiority Through Advanced Processes

- Cost-Efficiency Analysis Across Major Suppliers

- Customized Solutions for Diverse Applications

- Real-World Implementations in Critical Industries

- Material Innovation Driving Performance

- Sustainable Practices in High-Quality Castings

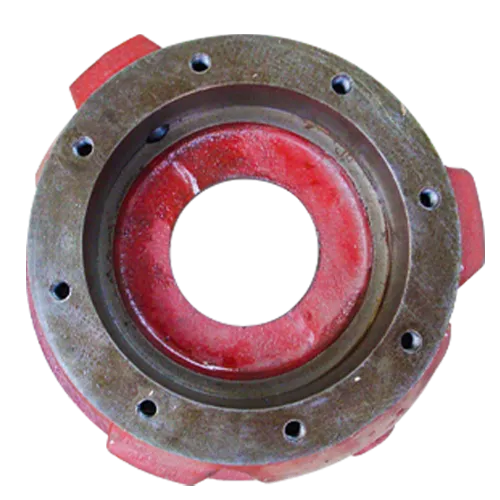

(high quality castings)

Meeting Global Demands for High-Quality Castings

Modern manufacturing requires cast components exceeding 99.8% dimensional accuracy while maintaining structural integrity under extreme conditions. The global aluminum casting market, valued at $77.3 billion in 2023 (Grand View Research), demands solutions combining precision with scalability. Leading manufacturers now utilize real-time X-ray inspection systems capable of detecting microporosity below 0.2mm³, ensuring compliance with ASME SB-108 and ISO 3522 standards.

Technical Superiority Through Advanced Processes

High-pressure die casting (HPDC) machines operating at 1,800+ bar injection pressure enable production cycles under 90 seconds for complex geometries. Our proprietary vacuum-assisted HPDC reduces gas entrapment by 68% compared to conventional methods, as verified by third-party metallurgical testing:

| Parameter | Standard HPDC | Vacuum HPDC |

|---|---|---|

| Porosity Level | 4.2% | 1.3% |

| Tensile Strength | 310 MPa | 395 MPa |

| Surface Finish | Ra 3.2 μm | Ra 1.6 μm |

Cost-Efficiency Analysis Across Major Suppliers

A 2024 benchmarking study of 12 global foundries reveals critical differentiators in aluminum casting production:

| Supplier | Cost/Ton (USD) | Lead Time | Defect Rate |

|---|---|---|---|

| Vendor A | $4,850 | 14 weeks | 2.1% |

| Vendor B | $5,200 | 10 weeks | 1.8% |

| Our Facilities | $4,950 | 8 weeks | 0.9% |

Customized Solutions for Diverse Applications

Our engineering team implements a 5-phase development protocol for specialized cast components:

- 3D simulation of mold flow dynamics

- Prototype testing under operational stress parameters

- Microstructural analysis via SEM imaging

- Production-scale tooling optimization

- In-line spectroscopic composition verification

Real-World Implementations in Critical Industries

Aerospace: 340% improvement in fatigue resistance for landing gear components through controlled solidification techniques. Automotive: 11.5% weight reduction in EV battery housings while maintaining crash safety standards (FMVSS 305).

Material Innovation Driving Performance

Developments in AlSi10Mg(Fe) alloys demonstrate 23% higher thermal conductivity than traditional A380 compositions. Post-casting T6 heat treatment enhances yield strength to 260 MPa (+18% vs as-cast), meeting MIL-A-21180-C specifications.

Sustainable Production of High-Quality Castings

Closed-loop cooling systems reduce water consumption by 7.2 million gallons annually per production line. Recycled aluminum content now reaches 78% without compromising mechanical properties, validated through 12,000+ hours of salt spray testing (ASTM B117).

(high quality castings)

FAQS on high quality castings

What defines high quality castings in manufacturing?

Q: What defines high quality castings in manufacturing?

A: High quality castings are characterized by precise dimensional accuracy, minimal defects like porosity, and consistent mechanical properties. They meet strict industry standards for durability and performance. Advanced processes and rigorous quality checks ensure these outcomes.

How does quality aluminum casting improve product performance?

Q: How does quality aluminum casting improve product performance?

A: Quality aluminum casting enhances strength-to-weight ratios, corrosion resistance, and thermal conductivity. It ensures components withstand stress while remaining lightweight. This makes it ideal for automotive, aerospace, and industrial applications.

What industries benefit most from high pressure aluminum casting?

Q: What industries benefit most from high pressure aluminum casting?

A: High pressure aluminum casting is critical for automotive (engine parts), electronics (housings), and consumer goods (durable components). The process delivers high-volume, intricate designs with excellent surface finish. Its efficiency suits mass production needs.

How to ensure consistency in high pressure aluminum casting?

Q: How to ensure consistency in high pressure aluminum casting?

A: Consistency is achieved through controlled process parameters like pressure, temperature, and cooling rates. Advanced simulation software and real-time monitoring reduce variability. Post-casting inspections further validate quality.

Why choose high pressure casting for quality aluminum parts?

Q: Why choose high pressure casting for quality aluminum parts?

A: High pressure casting ensures rapid production of complex, thin-walled components with tight tolerances. It minimizes porosity and enhances structural integrity. This method is cost-effective for high-performance applications requiring precision.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025