Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Properties and Applications of 1.0619% Carbon Steel For Various Industrial Needs

Understanding 1.0619% Steel Properties and Applications

Steel has been an integral part of industrial development, serving as the backbone of modern infrastructure and manufacturing. Among the vast array of steel grades available, 1.0619% steel, categorized as low-alloy steel, plays a crucial role in various applications due to its unique composition and beneficial properties.

Composition and Characteristics

1.0619% steel is classified under the EN 10083-2 standard, where the percentage indicates the carbon content. Specifically, it contains approximately 0.06% to 0.09% carbon and additional alloying elements, optimizing its mechanical properties. The low carbon content allows for enhanced weldability and ductility, making it an ideal choice for applications that require forming without compromising strength.

The steel's alloying elements might include manganese, which helps in improving hardenability, and silicon, which enhances strength and toughness. The low carbon content also makes it less brittle than higher carbon steels, allowing for better performance under stress. Its yield strength typically ranges from 300 MPa to 450 MPa, depending on the treatment it has undergone, and its tensile strength can reach up to 600 MPa.

Understanding 1

.0619% Steel Properties and ApplicationsThe mechanical properties of 1.0619% steel are influenced significantly by heat treatment processes. Normalizing or quenching and tempering can be applied to further enhance its strength and hardness. This versatility makes it favorable for various structural and mechanical applications.

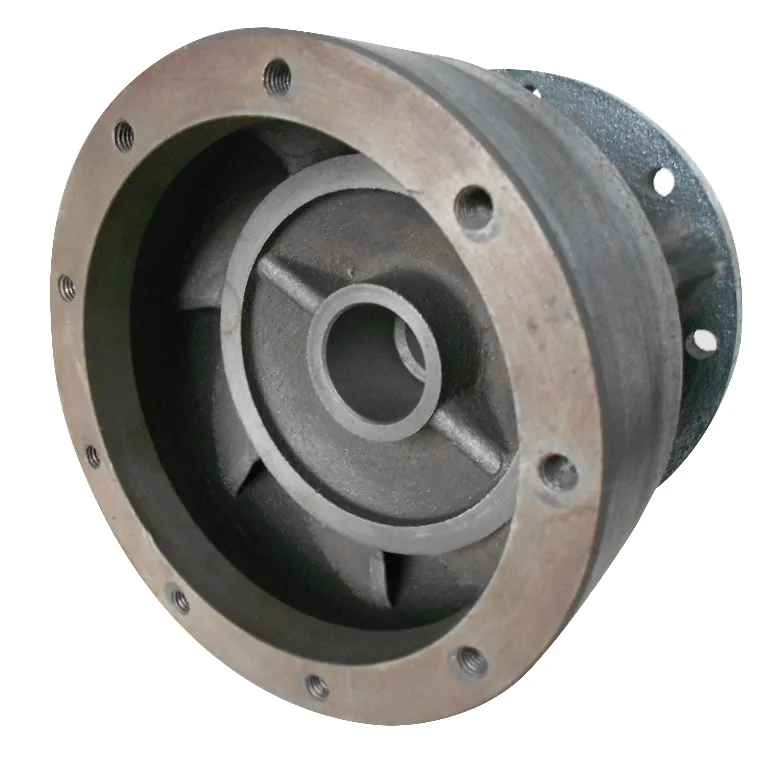

1.0619 steel

One of the defining aspects of this steel is its toughness. It exhibits excellent impact resistance, which is critical in applications where the material might be subjected to shock or sudden loading. Additionally, the weldability of 1.0619% steel permits it to be easily fabricated and manipulated for various applications, significantly lowering production costs and time.

Applications

1.0619% steel finds applications in a multitude of industries, primarily due to its balance of strength, weldability, and toughness. One common use is in the manufacturing of components for the automotive industry, such as frames, brackets, and other structural elements that require high durability yet are not excessively heavy.

In machinery construction, this steel is often utilized in the production of gears, shafts, and other components where both strength and ductility are essential. Moreover, it is a preferred choice for pipelines and pressure vessels, as it can withstand the mechanical stresses involved in these applications.

In addition to its structural applications, 1.0619% steel is also employed in the production of tools and dies, where its hardness and wear resistance come into play. Fabricators often choose this steel grade when producing parts that require precise tolerances and characteristics that remain stable under varying operational conditions.

Conclusion

In summary, 1.0619% steel embodies a unique blend of properties that make it a vital material in numerous engineering fields. With its excellent weldability, ductility, and strong mechanical performance, it caters to a wide range of industrial needs. As industries evolve and demand more from their materials, the significance of low-alloy steels like 1.0619% steel continues to grow, demonstrating that sometimes, the right balance can lead to exceptional outcomes. Whether in automotive, machinery, or construction applications, this steel grade stands out as a reliable choice in the complex world of metallurgy.