Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits of Die Casting in Aluminum Manufacturing Processes

The Advantages and Applications of Die Casting Aluminium

Die casting is a highly efficient manufacturing process that allows for the production of complex metal parts through the use of molds or dies. Among various metals suitable for die casting, aluminium is the most popular choice due to its unique properties and advantages. This article delves into the benefits of die casting aluminium, its applications, and why it is a preferred method in various industries.

Advantages of Die Casting Aluminium

One of the primary benefits of die casting aluminium is its lightweight nature. Aluminium has a low density, which makes parts produced through this process considerably lighter than those made from other metals like steel or iron. This quality is particularly advantageous in industries like automotive and aerospace, where reducing weight is crucial for improving fuel efficiency and overall performance.

Another significant advantage is the excellent structural integrity of aluminium die castings. The process allows for precise control over the metal's cooling rate, which results in a fine-grained microstructure. This feature enhances the mechanical strength of the parts, making them robust and durable. Additionally, aluminium boasts excellent corrosion resistance, which further extends the lifespan of the produced components, particularly in harsh environments.

Die casting also provides exceptional detail and dimensional accuracy. The process allows for the production of intricate geometries with tight tolerances, which is essential for components that must fit and function cohesively in assemblies. This level of precision reduces the need for extensive secondary machining processes, thereby cutting down manufacturing costs and lead times.

Energy Efficiency and Sustainability

Die casting aluminium is also recognized for its energy efficiency. The process is typically faster than other manufacturing methods, enabling higher production rates and lower overall energy consumption per unit. Furthermore, aluminium is a highly recyclable material. The ability to reuse aluminium scrap not only conserves natural resources but also reduces the environmental impact associated with the extraction and processing of raw materials.

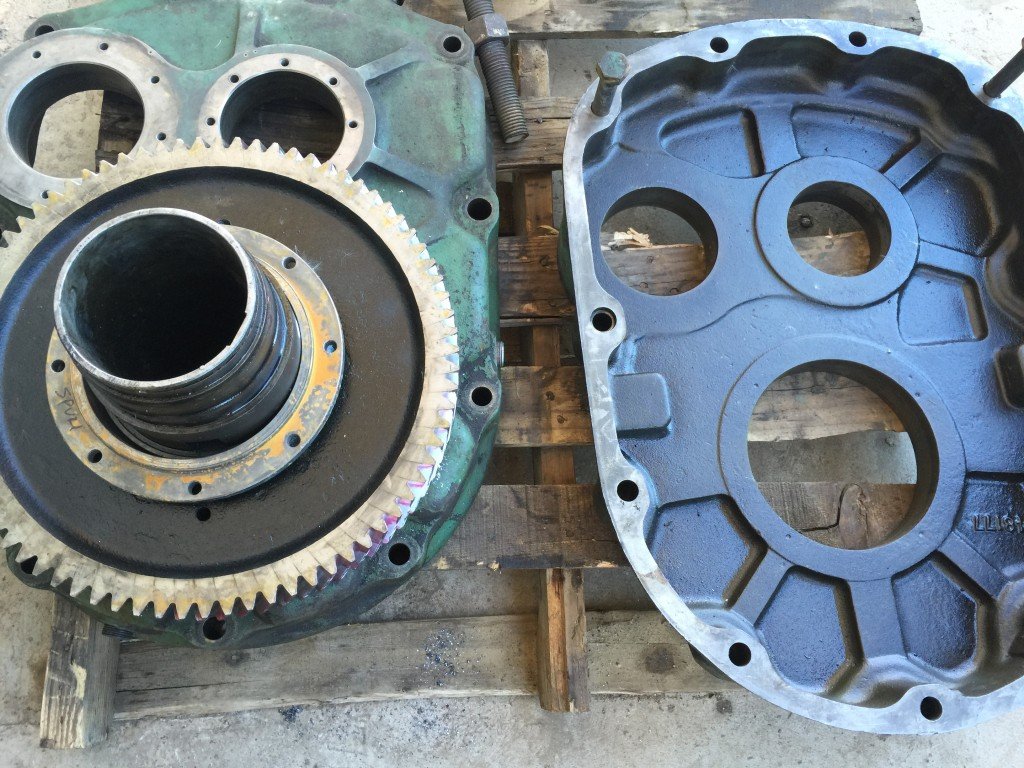

die casting aluminium

Applications of Die Casting Aluminium

Given its advantageous properties, die casting aluminium finds extensive applications across various industries. In the automotive sector, aluminium die cast parts are utilized for engine components, transmission housings, and structural parts like wheel rims. The lightweight nature of these components contributes significantly to fuel efficiency.

In the aerospace industry, where weight savings are paramount, aluminium die casting is employed to create complex structural components, fuselage parts, and internal brackets that need to support considerable loads while maintaining low weight. The high strength-to-weight ratio of die-cast aluminium parts helps enhance the overall performance of aircraft.

Electronics manufacturers also benefit from aluminium die casting. The process is used to produce housings and enclosures that protect sensitive electronic components. The material’s ability to dissipate heat effectively and its electromagnetic shielding properties are critical for protecting electronics and enhancing their performance.

Moreover, the consumer goods sector utilizes die casting to create aesthetically pleasing and functional products, including kitchen appliances, tools, and decorative items. The ability to produce high-quality finishes and intricate designs makes aluminium die casting an attractive option for manufacturers aiming to meet consumer demands.

Conclusion

Die casting aluminium presents a range of advantages, including lightweight properties, structural integrity, precision, energy efficiency, and sustainability. Its wide applicability across multiple industries, from automotive to electronics, showcases its versatility and importance in modern manufacturing. As technology continues to evolve, the methods and materials associated with die casting aluminium are likely to improve further, solidifying its place as a vital process in the production of high-quality metal parts.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025