Mobile:+86-311-808-126-83

Email:info@ydcastings.com

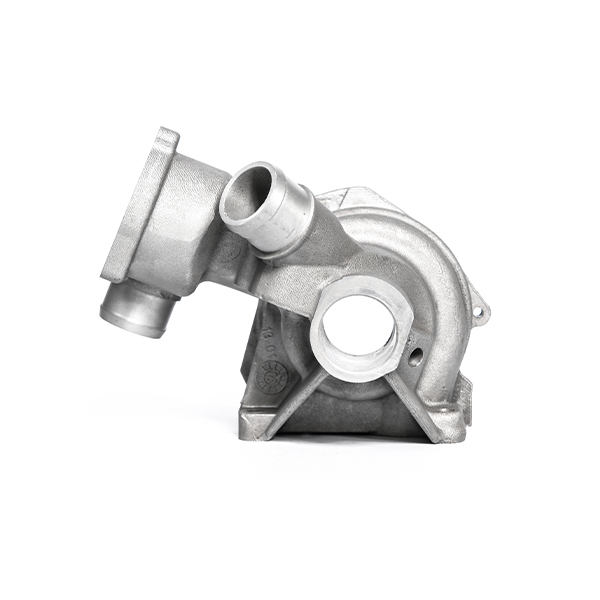

enclosed impeller

Enclosed Impeller An Overview of Design and Application

The enclosed impeller, a critical component in numerous fluid machinery applications, is engineered to promote the efficient movement of fluids within pumps, blowers, and compressors. Unlike open impellers, which expose the blades directly to the fluid, enclosed impellers are encased, adding a layer of protection and offering unique advantages in various operational contexts. This article delves into the design features, operational principles, advantages, and applications of enclosed impellers.

Design Features

Enclosed impellers consist of blades that are situated between two parallel enclosed plates, often referred to as shrouds. The design of these impellers can significantly influence their performance. The geometry of the blades, including their length, width, and angle, is tailored to optimize fluid dynamics, minimize turbulence, and enhance efficiency. Additionally, the shrouded nature of the impeller serves to contain the fluid, directing it in a controlled manner toward the discharge, which can lead to increased pressure and flow rates.

Materials used in constructing enclosed impellers are also crucial. They must endure not only the pressure exerted by the fluid but also resist wear and corrosion from various substances. Common materials include stainless steel, cast iron, and specialized alloys, which are chosen based on the fluid properties and operational environment.

Operational Principles

The operational principles of enclosed impellers center around converting mechanical energy into fluid energy. When the impeller rotates, it imparts kinetic energy to the fluid, which is then transformed into pressure energy as the fluid moves through the pump or compressor. This transformation is facilitated by the design of the impeller – specifically, the way the blade shape accelerates the fluid.

As the enclosed impeller spins, the fluid is drawn into the eye of the impeller, guided by the rotating blades. The enclosed design helps to maintain a consistent flow and pressure throughout the process, which is crucial in applications where variability can lead to inefficiencies or failures. The containment of the fluid also aids in reducing the likelihood of cavitation, a phenomenon that can seriously damage impellers and decrease the overall performance of the machinery.

enclosed impeller

Advantages

One of the primary advantages of enclosed impellers is their ability to handle a diverse range of fluids, including those that are abrasive, corrosive, or contain solids. The shrouded design protects the blades from direct exposure to the fluid, which extends their lifespan and reduces maintenance costs. Additionally, enclosed impellers typically operate more efficiently than open impellers, as they can better manage fluid flow and pressure.

Another notable advantage is the reduced risk of cavitation. Because the enclosed impeller maintains a larger pressure differential, it can effectively minimize the conditions that lead to cavitation, hence enhancing the reliability of the system. Moreover, enclosed impellers tend to be quieter in operation compared to their open counterparts, making them suitable for use in residential areas or environments where noise reduction is a priority.

Applications

Enclosed impellers are widely utilized across various industries. In water treatment facilities, they play a pivotal role in pumping large volumes of water. In chemical processing, enclosed impellers ensure the safe transport of corrosive substances. Additionally, they are commonly found in HVAC systems, where they contribute to the circulation of air and coolant fluids.

In the oil and gas industry, enclosed impellers are essential for enhancing efficiency in both upstream and downstream operations, from extraction to refining. Furthermore, applications in food and beverage processing benefit from enclosed impellers, as they help maintain hygiene standards while ensuring the safe movement of products.

Conclusion

In summary, the enclosed impeller serves as a cornerstone in fluid machinery applications, providing a reliable, efficient, and durable solution for fluid transportation. By understanding its design features, operational principles, advantages, and widespread applications, industries can better harness the capabilities of this critical component, ultimately enhancing performance and efficiency across various operational landscapes. As technology continues to advance, the design and application of enclosed impellers are likely to evolve, paving the way for even greater efficiency and innovation in fluid dynamics.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025