Mobile:+86-311-808-126-83

Email:info@ydcastings.com

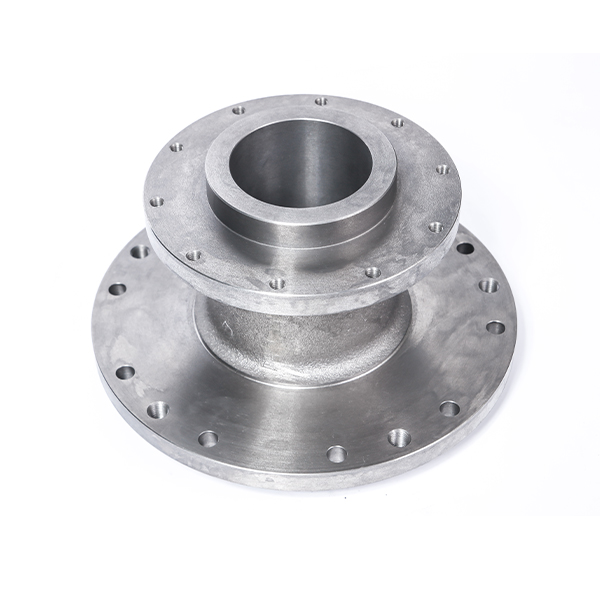

duplex steel casting

Understanding Duplex Steel Casting A Comprehensive Overview

Duplex steel, a combination of both austenitic and ferritic stainless steels, boasts unique properties that make it a popular choice in various industrial applications. Duplex steel casting has gained traction in sectors such as oil and gas, marine, and chemical processing industries due to its exceptional resistance to corrosion, strength, and high-temperature durability. This article delves into the intricacies of duplex steel casting, its properties, applications, and advantages.

What is Duplex Steel?

Duplex steels are defined by their two-phase microstructure of austenite and ferrite, typically containing about 22% chromium, 5% nickel, and 3% molybdenum, along with other elements. This combination results in materials that possess superior mechanical properties, making them more robust than conventional stainless steels. The dual-phase structure provides a balanced combination of strength and ductility.

Properties of Duplex Steel

1. Corrosion Resistance Duplex steel exhibits remarkable resistance to various types of corrosion, including pitting and stress corrosion cracking. This feature makes it highly suitable for environments where chloride exposure is a concern, such as in marine and chemical processing applications.

2. Strength and Ductility Duplex steel has higher yield strength compared to austenitic steels, making it a preferred material when strength is a critical factor in design. Along with high strength, it retains excellent ductility, allowing for easier fabrication and forming processes.

3. Weldability The weldability of duplex steels is another advantage. They can be welded using various techniques without significant risk of detrimental phase formation or loss of corrosion resistance, provided the appropriate procedures are followed.

4. High-Temperature Performance Duplex steels maintain their strength and structural integrity at elevated temperatures, which is particularly beneficial in applications involving heat exposure.

The Casting Process

Duplex steel casting involves several key steps, including melting, mold preparation, pouring, and cooling. The process generally begins with the melting of raw materials in induction furnaces or electric arc furnaces. After achieving the desired composition, the molten duplex steel is poured into molds designed to shape the final part. Once poured, the metal is allowed to cool and solidify before undergoing finishing processes such as machining and surface treatment.

duplex steel casting

Applications of Duplex Steel Casting

1. Oil and Gas Industry Duplex steel is extensively used in offshore platforms, pipelines, and drilling rigs, where resistance to corrosive environments and high strength are paramount.

2. Marine Applications The marine industry utilizes duplex steel for components like ship fittings, valves, and other parts exposed to seawater, taking advantage of its excellent resistance to chloride-induced corrosion.

3. Chemical Processing In chemical plants, duplex steel is employed for tanks, reactors, and piping systems, where harsh chemicals may be present, requiring materials that can withstand corrosive environments.

4. Power Generation Duplex steel castings are used in components like heat exchangers and pressure vessels in power plants, benefiting from their ability to handle high temperatures and pressures.

Advantages of Duplex Steel Casting

Duplex steel casting offers several advantages over other materials

- Cost-Effectiveness While duplex steel may have a higher initial cost compared to traditional carbon steels, its longevity and reduced maintenance needs often lead to lower lifetime costs. - Enhanced Performance The unique combination of strength and corrosion resistance allows for the use of thinner sections in casting, reducing weight without compromising performance.

- Sustainability Duplex steel can be recycled without losing its fundamental properties, aligning with modern sustainability practices and reducing environmental impact.

Conclusion

Duplex steel casting is a vital technology in various industries due to its unique properties and advantages. Its combination of strength, ductility, and exceptional resistance to corrosion makes it an optimal choice for challenging applications. As industries continue to evolve, the demand for reliable materials like duplex steel will undoubtedly grow, affirming its role as a cornerstone of modern engineering solutions. Understanding its properties and applications will allow engineers and designers to make informed decisions when selecting materials for their projects.