Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the DT466 Exhaust Manifold Performance and Maintenance Considerations

The Importance of the DT466 Exhaust Manifold A Comprehensive Overview

The International DT466 is a robust, inline-six diesel engine that has earned a reputation for its durability and performance. Commonly used in various applications, from school buses to medium-duty trucks, the engine is well-known among fleet operators and mechanics alike. One of the critical components of the DT466 engine is its exhaust manifold, which plays a significant role in ensuring optimal performance and efficiency. This article explores the functions, features, and maintenance considerations of the DT466 exhaust manifold.

Understanding the Exhaust Manifold

The exhaust manifold is a crucial part of the engine's exhaust system. Its primary function is to collect exhaust gases produced by the engine cylinders and direct them into the exhaust pipe. In the case of the DT466, the exhaust manifold is specifically designed for high performance and durability, capable of withstanding the extreme conditions encountered in diesel engines.

Design and Construction

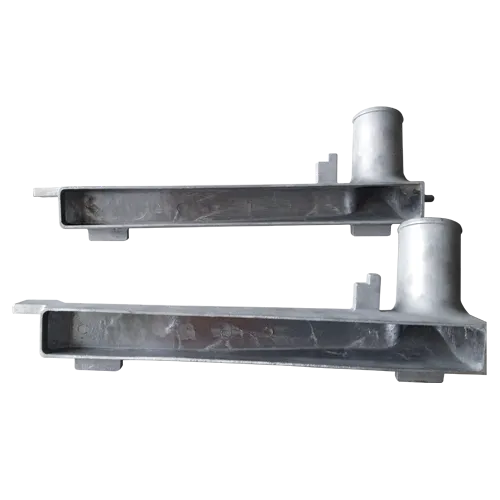

The DT466 exhaust manifold is typically made from high-quality cast iron, a material chosen for its heat resistance and structural integrity. This material allows the manifold to endure the high temperatures associated with diesel combustion while minimizing the risk of warping or cracking. The design features smooth passageways that facilitate the efficient flow of exhaust gases, reducing backpressure and enhancing overall engine performance.

The manifold's design also incorporates provisions for mounting accessories such as turbochargers, which are commonly used in diesel engines for improved efficiency and power output. Proper alignment and sealing are crucial, as any leaks can lead to performance issues and increased emissions, compromising engine efficiency.

Performance Implications

dt466 exhaust manifold

A properly functioning exhaust manifold plays a significant role in the engine's performance. Optimal exhaust flow is essential for maintaining the right balance of air and fuel, which directly affects power output and efficiency. In the DT466, the design of the exhaust manifold helps to ensure that exhaust gases are evacuated promptly, allowing for smoother intake of fresh air and better combustion.

Furthermore, any restrictions or leaks in the exhaust manifold can lead to poor performance, increased fuel consumption, and higher emissions. This is particularly critical in applications where fuel efficiency and regulatory compliance are primary concerns. Regular inspections and maintenance of the exhaust manifold are vital to prevent these issues from arising.

Maintenance and Common Issues

Like any engine component, the exhaust manifold in a DT466 requires regular maintenance and monitoring. Common issues include cracks and leaks, which can result from thermal cycling and the high-stress environment typical of diesel engines. Mechanics often recommend inspecting the manifold during routine service intervals to identify any potential issues early.

When cracks or leaks are discovered, it is crucial to address them promptly. In some cases, repair can involve welding or using specialized sealants, but severe damage may necessitate complete replacement of the manifold. It's also essential to examine the condition of the gaskets and mounting hardware, as worn or damaged components can lead to exhaust leaks.

Conclusion

The exhaust manifold is a vital component of the DT466 engine, contributing significantly to its performance and efficiency. Understanding its function and maintenance needs is essential for fleet operators and mechanics alike. Regular inspections, prompt repairs, and proper installation are important practices that ensure the longevity and reliability of the exhaust system.

In a world where every drop of fuel counts and emissions regulations are getting stricter, the significance of the exhaust manifold cannot be overstated. By investing time and resources in maintaining this critical component, operators can ensure their vehicles run smoothly and efficiently, allowing them to maximize performance while adhering to environmental standards. The DT466 exhaust manifold may seem like a small piece in the grand puzzle of diesel engine operation, but it plays a pivotal role in achieving optimal results. As always, routine maintenance and attention to detail will go a long way in extending the life of the engine and maintaining its performance.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025