Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Various Types of Impellers and Their Unique Functions in Fluid Dynamics

Understanding Different Types of Impellers

Impellers are crucial components in a wide range of machinery, particularly in pumps and turbines where they are used to move fluids. The design and functionality of an impeller significantly affect the efficiency and performance of these devices. Various types of impellers are tailored for specific applications, each with unique features and benefits. In this article, we will explore several commonly used types of impellers, their operating principles, and their applications.

1. Closed Impeller

Closed impellers are characterized by having two parallel plates or shrouds that house the blades. This design enhances fluid flow, as it prevents leakage and minimizes turbulence. Closed impellers are highly efficient and are commonly used in centrifugal pumps. They are ideal for applications requiring a steady flow of liquid, such as chemical processing and water supply systems. Their ability to maintain high efficiency even under varying flow conditions makes them a popular choice in industrial settings.

2. Open Impeller

In contrast to closed impellers, open impellers consist of blades without any shrouds. This design allows for easy passage of larger solids and is, therefore, suitable for handling slurries or liquids containing particles. Although open impellers typically exhibit lower efficiency compared to closed impellers, they are beneficial in applications where solids need to be conveyed. They are often found in wastewater treatment plants and certain agricultural applications, where the ability to handle abrasive materials is critical.

Semi-closed impellers, as the name suggests, are a blend of both closed and open designs. They incorporate a partial shroud, giving them enhanced performance while allowing larger solids to pass through. This makes them versatile in handling various fluids, including those with some solids. Semi-closed impellers are commonly used in agricultural irrigation systems and aquaculture, particularly for pumping water mixed with sediments.

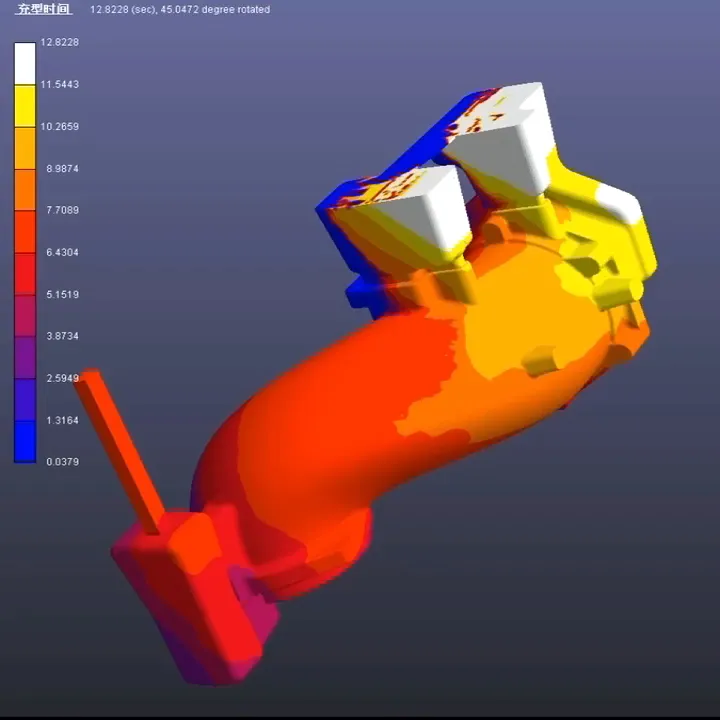

different types of impeller

4. Vortex Impeller

Vortex impellers are designed with a unique blade configuration that creates a vortex flow pattern. This design minimizes contact between the blades and the fluid, reducing shear and making them ideal for handling shear-sensitive fluids or mixtures with large solids. Vortex impellers are particularly useful in applications such as sewage pumping or when transporting liquids with fibrous materials. Their ability to manage challenging fluid characteristics while preventing clogging is a significant advantage.

5. Propeller Impeller

Propeller impellers are widely used in marine applications, particularly in boats and ships. They consist of blades arranged in a propeller configuration, allowing for efficient movement of water. Their design is optimized for creating thrust, making them suitable for high-flow applications. Propeller impellers can also be found in certain types of mixers and aerators, where they enhance fluid movement and promote oxygenation in water bodies.

6. Radial and Axial Impellers

Impellers can also be categorized based on their flow direction radial and axial. Radial impellers push fluid outward from the center, making them ideal for high-pressure applications. They are commonly found in centrifugal pumps. On the other hand, axial impellers move fluid parallel to the impeller axis, which is typical for applications requiring high flow rates with lower pressure. Axial flow pumps are used in situations like drainage and flood control where a large volume of fluid needs to be moved efficiently.

Conclusion

The choice of impeller type significantly impacts the performance and efficiency of fluid management systems. Understanding the various types of impellers—closed, open, semi-closed, vortex, propeller, radial, and axial—enables engineers and operators to select the most appropriate design for their specific applications. By matching the impeller configuration to the characteristics of the fluid being managed, industries can achieve optimal efficiency, reduce operational costs, and enhance overall system performance. As technology advances, innovations in impeller design will continue to evolve, further improving their functionality and expanding their applications across diverse sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025