Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Applications of Die Casting Products in Manufacturing

The Evolution and Applications of Die Casting Products

Die casting is a manufacturing process that has become integral in the production of various metal products. This innovative technique allows for the creation of complex shapes with high precision and excellent surface finish. Over the decades, die casting has evolved significantly, finding widespread applications in numerous industries, ranging from automotive and aerospace to electronics and consumer goods.

Understanding the Die Casting Process

At its core, die casting involves forcing molten metal into a mold cavity under high pressure. The molds, known as dies, are made from highly durable materials such as steel, allowing them to withstand the thermal and mechanical stresses of repeated use. There are primarily two types of die casting processes hot chamber and cold chamber.

1. Hot Chamber Die Casting This method is commonly used for zinc, lead, and magnesium alloys. The molten metal is kept in a chamber and injected into the mold using a plunger. The hot chamber method is efficient for metals with low melting points, as it minimizes heat loss.

2. Cold Chamber Die Casting Suitable for aluminum and other high melting point alloys, the cold chamber process involves pouring molten metal into a separate chamber before injection into the mold. This process is beneficial for metals that require higher temperatures for melting, providing more material flexibility.

Advantages of Die Casting

The die casting method has several advantages that contribute to its popularity

- High Precision Die casting produces components with tight tolerances, minimizing the need for secondary machining processes. This precision is crucial in industries where parts must fit together perfectly.

- Complex Geometries The ability to create intricate shapes makes die casting ideal for producing complex designs that might otherwise be challenging or costly with other manufacturing methods.

- Surface Finish Parts made through die casting often have a smooth finish, which allows them to be used directly without extensive secondary processing

.

- Material Efficiency Die casting minimizes waste and allows the use of secondary raw materials, contributing to environmentally sustainable practices.

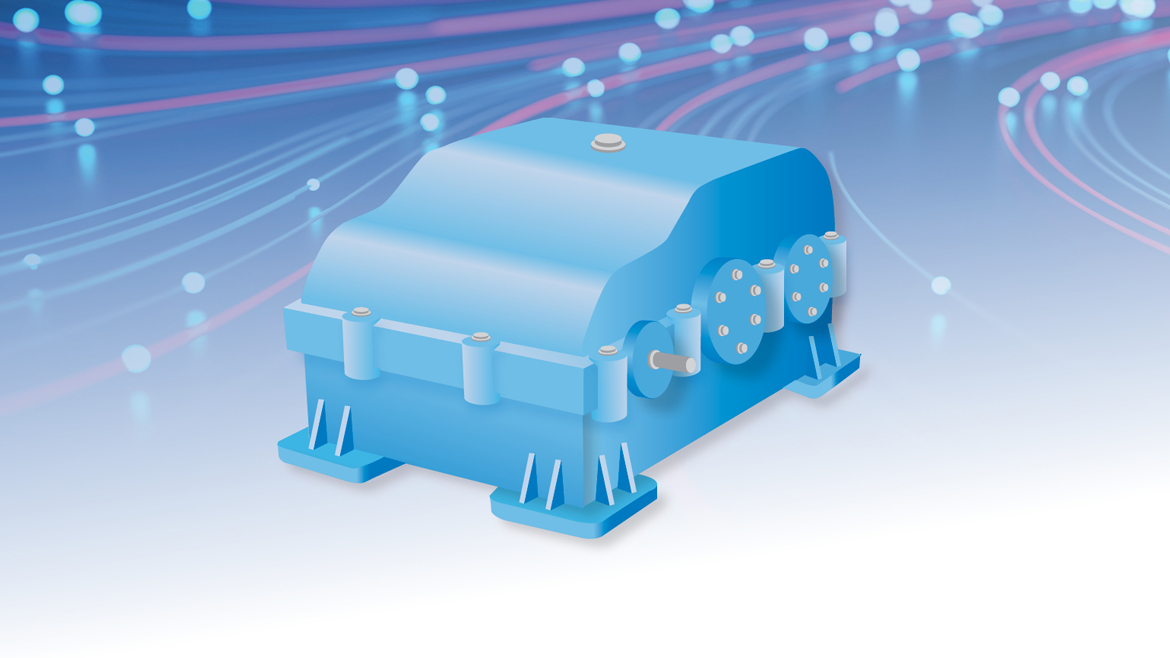

die casting products

Industry Applications

Die casting products are prevalent across various sectors. Here are some notable applications

1. Automotive Industry Die casting is widely used in the production of engine blocks, transmission cases, and various structural components. The lightweight and high-strength characteristics of die-cast aluminum make it an ideal choice for improving fuel efficiency and performance in vehicles.

2. Aerospace Sector The aerospace industry requires parts that can withstand extreme conditions. Die casting allows for the creation of lightweight yet durable components, such as housings for engines and structural components for aircraft.

3. Consumer Electronics With the rise of technology, die casting has found its niche in manufacturing enclosures and structural parts for smartphones, laptops, and other electronic devices. This process helps in maintaining the sleek designs that consumers demand.

4. Home Appliances Many modern appliances utilize die-cast components, from small parts in washing machines to larger pieces in refrigerators. The durability and aesthetics provided by die casting contribute to the overall appeal and functionality of these products.

Future Trends in Die Casting

As technology advances, the die casting industry is likely to witness further innovations. One such trend is the development of new alloys and materials that enhance the properties of die-cast products. Additionally, automation and advanced robotics are poised to streamline the manufacturing process, improving efficiency and reducing labor costs.

Moreover, as industries continue to focus on sustainability, the recycling of die-cast metals presents an opportunity for environmental impact reduction. Manufacturers are increasingly looking at ways to incorporate recycled materials into their production processes, further enhancing the eco-friendliness of die casting.

Conclusion

In conclusion, die casting products have become a cornerstone of modern manufacturing. With their high precision, design flexibility, and material efficiency, they are essential across various industries. As technology continues to evolve, the future of die casting looks promising, paving the way for smarter, more sustainable production methods that can meet the demands of an ever-changing market.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025