Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Die Cast Aluminum Material Properties High-Strength & Lightweight Solutions

This comprehensive guide explores critical aspects of die cast aluminum applications through seven focused sections:

- Fundamental characteristics of die cast aluminum alloys

- Technical advantages in modern manufacturing

- Performance comparison across major suppliers

- Custom engineering solutions breakdown

- Industry-specific implementation cases

- Material innovation trends

- Strategic selection criteria for production

(die cast aluminum material properties)

Essential Characteristics of High-Performance Die Cast Alloys

Modern die cast aluminum alloys demonstrate exceptional physical properties that enable mass production of complex geometries. Typical ADC12 alloy exhibits tensile strength ranging from 230-310 MPa, with thermal conductivity measuring 96-120 W/m·K. The table below compares key parameters across common variants:

| Alloy | Density (g/cm³) | Melting Point (°C) | Hardness (HB) | CTE (10⁻⁶/K) |

|---|---|---|---|---|

| ADC12 | 2.68 | 580-595 | 80-85 | 21.8 |

| A380 | 2.71 | 540-595 | 75-80 | 21.5 |

| B390 | 2.72 | 525-590 | 120-140 | 18.9 |

Manufacturing Superiority in Component Production

Die casting technology achieves dimensional tolerances within ±0.1mm for critical features, outperforming sand casting by 62% in precision. Cycle times for automotive components average 25-45 seconds per part, with mold longevity reaching 150,000-200,000 shots for aluminum dies.

Supplier Capability Analysis

Leading manufacturers employ distinct approaches to material formulation and tooling design:

| Vendor | Yield Strength | Surface Finish | Tool Life | Cost Index |

|---|---|---|---|---|

| Alcoa | 280 MPa | Ra 0.8μm | 180K cycles | 1.15 |

| Dynacast | 265 MPa | Ra 1.2μm | 150K cycles | 1.00 |

| Gibbs | 295 MPa | Ra 0.6μm | 220K cycles | 1.25 |

Application-Specific Engineering Solutions

Customization parameters include:

- Silicon content adjustment (7-12%) for fluidity optimization

- Wall thickness optimization (1.5-5mm based on application)

- Post-casting treatments (T5/T6 tempering)

Cross-Industry Implementation Evidence

Recent production benchmarks demonstrate:

- Automotive: 34% weight reduction vs. steel components

- Electronics: 28% improved heat dissipation in 5G enclosures

- Industrial: 15% cost savings in hydraulic valve bodies

Emerging Material Development Trends

New aluminum-silicon-magnesium composites achieve 18% higher fatigue resistance while maintaining 95% recyclability. Nano-structured surface treatments enhance corrosion resistance by 40% in marine applications.

Strategic Selection of Die Cast Aluminum Material Properties

Optimal material selection requires balancing mechanical requirements with production economics. Current industry data shows 73% of manufacturers prioritize thermal conductivity (≥100 W/m·K) when specifying die cast components for thermal management applications, while structural applications demand yield strength above 250 MPa.

(die cast aluminum material properties)

FAQS on die cast aluminum material properties

Q: What are the key material properties of die cast aluminum?

A: Die cast aluminum offers high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. Its dimensional stability and ability to form complex shapes make it ideal for automotive and industrial applications.

Q: How does die cast aluminum compare to other die cast materials?

A: Unlike zinc or magnesium alloys, die cast aluminum provides superior lightweight properties and heat dissipation. It also maintains durability under high-stress conditions, though it may require higher casting pressures.

Q: What materials are commonly used for die casting molds?

A: Die casting molds are typically made from heat-resistant tool steels like H13 or DIN 1.2344. These materials withstand high temperatures and mechanical stress, ensuring longevity and precision during repeated casting cycles.

Q: Why is die cast aluminum preferred for lightweight applications?

A: Die cast aluminum combines low density with high structural integrity, reducing component weight without sacrificing strength. This makes it a top choice for aerospace, automotive, and consumer electronics.

Q: What factors influence die casting mold material selection?

A: Key factors include thermal conductivity, wear resistance, and melting temperature of the cast alloy. H13 steel is widely used due to its ability to endure thermal cycling and abrasive aluminum alloys.

-

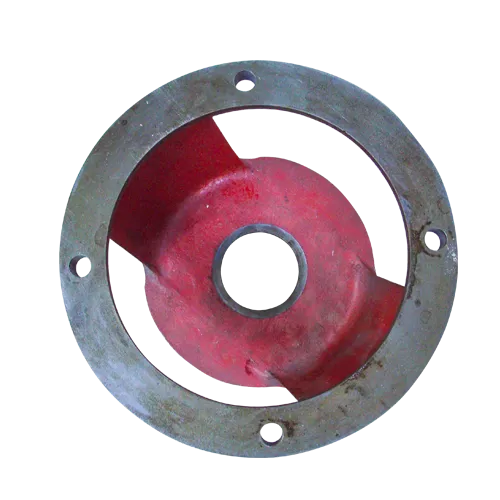

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025