Mobile:+86-311-808-126-83

Email:info@ydcastings.com

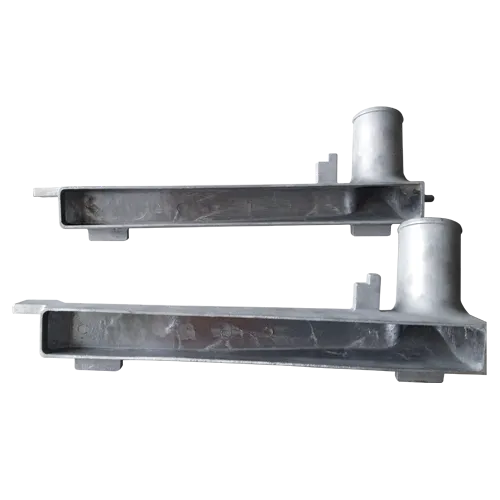

custom aluminum casting

Custom Aluminum Casting A Comprehensive Overview

Aluminum casting is a vital manufacturing process that involves pouring molten aluminum into a mold to create specific shapes and components. This process has gained immense popularity due to the unique properties of aluminum, including its lightweight, corrosion resistance, and excellent strength-to-weight ratio. Custom aluminum casting, in particular, allows manufacturers to create tailored solutions that meet the precise requirements of various industries, including automotive, aerospace, construction, and consumer goods.

The Advantages of Custom Aluminum Casting

1. Design Flexibility One of the primary benefits of custom aluminum casting is the design flexibility it offers. Manufacturers can design intricate shapes and structures that would be difficult or impossible to achieve through other manufacturing methods. Advanced casting techniques, such as die casting, sand casting, and investment casting, enable the creation of complex geometries with high precision.

2. Cost-Effectiveness While the initial setup costs for custom aluminum casting can be significant, the overall cost-effectiveness is one of its strongest advantages. Once the mold is created, mass production becomes efficient and economical, leading to lower unit costs. Additionally, aluminum’s recyclability means that manufacturers can often save on material costs by reusing scrap aluminum in the casting process.

3. Quality and Durability Aluminum castings exhibit excellent mechanical properties, including high strength and resistance to deformation under stress. Furthermore, aluminum's inherent corrosion resistance enhances the longevity of cast parts, making them suitable for various demanding applications. Custom aluminum castings can also be treated or coated to further enhance their performance in specific environments.

4. Rapid Prototyping In today's fast-paced market, rapid prototyping is essential for testing new designs and concepts. Custom aluminum casting allows manufacturers to quickly produce prototypes that can be tested for functionality and performance. This iterative process helps in refining designs before full-scale production begins, significantly reducing time to market.

Industries Utilizing Custom Aluminum Casting

Custom aluminum casting finds applications across a wide range of industries. In the automotive sector, it is used to produce lightweight yet strong components, such as engine blocks, transmission housings, and structural parts, contributing to fuel efficiency and performance. The aerospace industry also benefits from aluminum casting, as it allows for the production of complex components that meet stringent weight and safety standards.

In the construction industry, custom aluminum castings are used for architectural elements, window frames, and support structures, providing both aesthetic appeal and structural integrity. Moreover, consumer goods manufacturers leverage aluminum casting to create durable and stylish products, from kitchenware to electronic enclosures.

custom aluminum casting

The Custom Aluminum Casting Process

The custom aluminum casting process typically involves several key steps

1. Design and Pattern Making The process begins with creating a detailed design using CAD software. A pattern representing the final product is then made, often from wood, metal, or plastic.

2. Mold Creation The pattern is used to create a mold, which can be made from sand, metal, or other materials, depending on the casting method chosen.

3. Melting and Pouring Aluminum is melted in a furnace and then poured into the mold. Careful temperature control is essential to ensure optimal flow and prevent defects.

4. Cooling and Solidification Once poured, the aluminum cools and solidifies in the mold, taking on its final shape.

5. Finishing After removing the casting from the mold, it may require additional finishing processes such as machining, surface treatment, or coating to achieve the desired specifications and appearance.

Conclusion

Custom aluminum casting plays a pivotal role in modern manufacturing, offering unparalleled benefits in design flexibility, cost-effectiveness, and product quality. As industries continue to evolve and demand innovative solutions, the importance of custom aluminum casting is only set to grow. Manufacturers investing in this technology can expect to see significant advantages in product performance and market competitiveness, making custom aluminum casting a key component of successful production strategies. With its ability to meet diverse needs across various sectors, custom aluminum casting is truly a cornerstone of modern manufacturing excellence.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025