Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Functionality and Design of Compression End Caps in Modern Applications

Understanding Compression End Caps Essential Components in Packaging

In the world of packaging, the details often make a significant difference in the efficiency and effectiveness of product transport and storage. One of the crucial components that frequently goes unnoticed is the compression end cap. This article will delve into what compression end caps are, their importance in various industries, and the benefits they offer.

What are Compression End Caps?

Compression end caps are specialized closures used in packaging, particularly for cylindrical containers such as tubes, bottles, and pipes. They are often made from materials like plastic, metal, or composites and are designed to securely seal the ends of a package. These caps are rendered to withstand significant pressure, hence the term 'compression.' The design ensures that they fit snugly onto the container, preventing leakage, contamination, or product spoilage.

Importance in Various Industries

1. Pharmaceuticals In the pharmaceutical industry, maintaining product integrity is paramount. Compression end caps are designed to provide a tight seal to ensure that medications are protected from external contaminants and moisture. They also play a critical role in maintaining the shelf life of sensitive products.

2. Food and Beverage For the food and beverage industry, compression end caps are essential in packaging products like sauces, condiments, and juices. Their airtight seal helps in preserving the freshness and flavor of the contents, thereby preventing spoilage and waste.

3. Cosmetics The cosmetic industry utilizes compression end caps to package substances like creams, lotions, and gels. These caps not only offer protection but also add to the aesthetic appeal of the product, with various designs and finishes available.

4. Industrial Applications In industrial settings, compression end caps are used for containers that hold hazardous materials. They are designed to withstand extreme conditions and provide a secure seal that prevents leaks, reducing the risk of accidents and ensuring environmental safety.

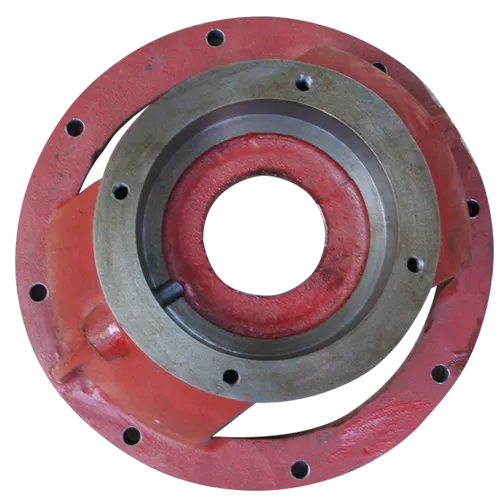

compression end cap

Benefits of Compression End Caps

1. Leak Prevention One of the most significant advantages of using compression end caps is their ability to prevent leaks. This is especially important for liquids or semi-liquids, as leaks can lead to product loss and environmental hazards.

2. Cost-Effective By ensuring that products remain intact during storage and transportation, compression end caps help to minimize loss and waste. This cost-effective approach is beneficial for companies looking to enhance their profitability.

3. Customization Options Compression end caps can be customized in various shapes, sizes, and materials to meet specific product requirements. This level of customization allows businesses to align their packaging with branding and functionality needs.

4. Enhanced Safety The robust design of compression end caps contributes to overall safety, particularly for hazardous materials. These caps can endure pressure and impact, ensuring that contents are safely contained.

5. Recyclable Options With a growing emphasis on sustainability, many manufacturers are producing compression end caps from recyclable materials. This is an essential consideration for companies looking to reduce their environmental footprint.

Conclusion

In the complex landscape of packaging, the significance of compression end caps cannot be overstated. They provide essential safety, efficiency, and cost-effectiveness across various industries, from pharmaceuticals to cosmetics. As businesses continue to innovate and prioritize sustainability, compression end caps will remain a critical component of effective packaging solutions.

In summary, understanding the role and benefits of compression end caps is essential for anyone involved in product packaging or supply chain management. By choosing the right closure solutions, companies can enhance their operations, meet regulatory standards, and deliver superior products to consumers, all while safeguarding the environment.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025