Mobile:+86-311-808-126-83

Email:info@ydcastings.com

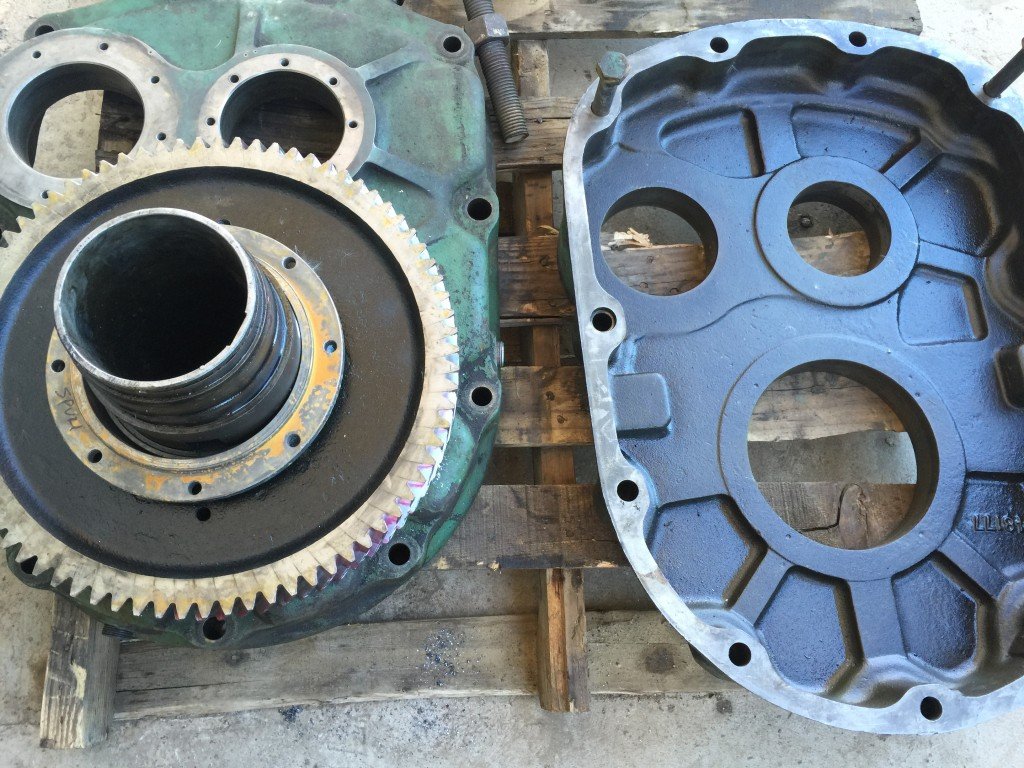

closed type impeller

Understanding Closed Type Impellers Design and Applications

In the world of fluid dynamics and engineering, impellers play a pivotal role in facilitating the movement of fluids within various systems. Among the various types of impellers, closed type impellers have garnered significant attention for their efficiency and performance in diverse applications. This article delves into the design, advantages, and applications of closed type impellers.

Design Features

Closed type impellers are characterized by their enclosed design, where the blades are nestled between two shrouds or covers. This closed configuration contrasts with open impellers, which lack the outer cover and are more exposed. The closed design serves several vital functions. Firstly, it ensures better fluid containment, minimizing leaks and turbulence that can disrupt flow efficiency. Secondly, the shroud enhances the structural integrity of the impeller, allowing it to withstand higher centrifugal forces, which is particularly crucial in high-speed applications.

The blades of a closed type impeller are often meticulously designed to optimize fluid flow and achieve maximum efficiency. By controlling the blade shape, size, and angle, engineers can tailor the impeller to specific performance requirements. This level of customization allows closed impellers to operate effectively across a range of flow rates and pressures.

Advantages of Closed Type Impellers

One of the primary advantages of closed type impellers is their efficiency in converting mechanical energy into fluid flow energy. The enclosed design reduces turbulence, allowing for a smoother and more streamlined flow of liquid. This enhanced efficiency can lead to significant energy savings, making closed impellers a preferred choice in applications where energy consumption is a critical factor.

Furthermore, the closed configuration offers improved hydraulic performance. Closed type impellers tend to generate higher pressure and flow rates compared to their open counterparts. This characteristic makes them ideal for high-head applications, such as in water supply systems, irrigation, and fire protection systems.

closed type impeller

Another significant benefit of closed type impellers is their suitability for pumping viscous fluids

. The shrouded design and precise blade angles help maintain the flow of viscous liquids, reducing the likelihood of clogging and ensuring smooth operation. As a result, closed type impellers find extensive use in industries dealing with thick or viscous substances, such as chemical processing and food production.Applications

The versatility of closed type impellers extends across various industries and applications. One notable area of application is in centrifugal pumps, where they are commonly employed to move liquids from one location to another efficiently. In wastewater treatment plants, closed type impellers play a crucial role in transporting and managing effluent, contributing to effective filtration and treatment processes.

In the manufacturing sector, closed type impellers are vital components of mixers and agitators, where they facilitate the blending of materials. Their ability to handle viscous substances makes them indispensable in the production of paints, adhesives, and various chemical formulations.

Moreover, closed type impellers are frequently utilized in HVAC (heating, ventilation, and air conditioning) systems. They assist in moving air through ducts and ventilation systems, contributing to climate control in residential, commercial, and industrial settings.

Conclusion

Closed type impellers are an integral part of many fluid handling systems, offering a unique combination of efficiency, performance, and versatility. Their design and features make them suitable for a wide array of applications, from pumping and mixing to air handling. As industries continue to prioritize energy efficiency and effective fluid dynamics, the relevance of closed type impellers is likely to grow, marking their importance in engineering and technology for the foreseeable future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025