Mobile:+86-311-808-126-83

Email:info@ydcastings.com

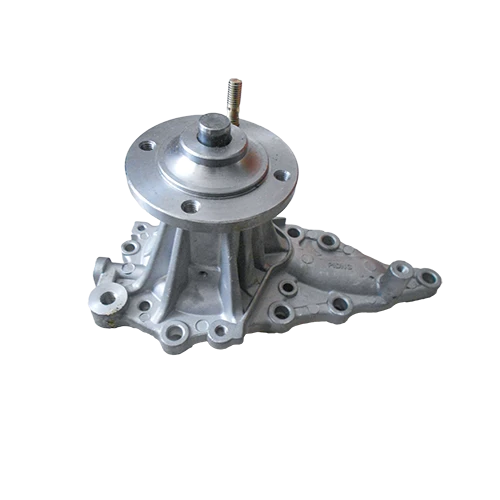

closed type impeller

Understanding Closed Type Impellers Design, Function, and Applications

Closed type impellers are a crucial component in various fluid dynamics applications, particularly in centrifugal pumps and other rotating equipment. Their design, which features a fully enclosed structure, distinguishes them from open impellers and allows for higher efficiency and pressure delivery. In this article, we will explore the design, functionality, and applications of closed type impellers, as well as their advantages and limitations in various industrial scenarios.

Design Features

The closed type impeller consists of two parallel plates with blades situated between them. This design provides a channel for the fluid to flow, and the geometry can significantly influence the performance of the pump or blower. The enclosed structure allows for better control of the fluid's path, reducing turbulence and minimizing the risk of cavitation—a phenomenon that can lead to severe damage and reduced efficiency.

The blades in closed impellers can be designed in various shapes and angles, adapting to the specific requirements of the application. The number of blades can also vary, with more blades often providing a smoother flow but at the cost of increased drag. Material selection is critical as well; commonly, stainless steel, bronze, or even plastic materials are used, depending on the type of fluid being handled and the operating conditions.

Functionality

Closed type impellers work by converting mechanical energy from a rotating shaft into kinetic energy in the fluid. As the impeller spins, it flings the fluid outward due to centrifugal force, increasing its velocity. The enclosed design ensures that the fluid is accelerated efficiently through the volute or diffuser that follows the impeller, converting the kinetic energy into pressure energy. This characteristic makes closed impellers particularly effective for applications requiring high pressure and flow rates.

Another significant advantage of closed type impellers is their ability to maintain performance over a broader range of operating conditions

. The enclosed design minimizes the potential for the fluid to escape, maintaining a consistent flow rate and reducing the chances of air entrainment, which can compromise performance.closed type impeller

Applications

Closed type impellers are widely used across various industries, including water treatment, chemical processing, HVAC systems, and oil and gas. In water treatment facilities, they are integral to moving water efficiently through filtration systems and treatment tanks. In the chemical industry, closed impellers help in transporting corrosive and non-corrosive fluids alike, owing to their durability and efficient design.

In HVAC systems, these impellers are used in fans and blowers to manage airflow for ventilation and heating applications. Their ability to maintain airflow against static pressure makes them a preferred choice for many heating and cooling systems. Similarly, in oil and gas operations, closed impellers serve as critical components in pumps that transport crude oil, natural gas, and other essential fluids across vast distances.

Advantages and Limitations

The primary advantages of closed type impellers include their high efficiency, compact design, and capability to handle pressurized fluids effectively. They tend to be quieter and produce less vibration compared to open impellers, making them suitable for applications where noise reduction is vital.

However, closed impellers also have some limitations. They can be more prone to clogging with solids or viscous fluids due to their enclosed design, which may require additional maintenance or the installation of pre-filters. Furthermore, the complex manufacturing process can lead to higher costs compared to simpler designs like open impellers.

Conclusion

In summary, closed type impellers play an essential role in modern fluid handling systems. Their efficient design and ability to deliver high pressure and flow rates make them indispensable in various industries. Understanding their functionality, applications, and the benefits they offer can help in selecting the right impeller type for specific needs, ensuring optimal performance and reliability in fluid management operations. As industries continue to evolve and require more efficient fluid handling solutions, closed type impellers will likely remain at the forefront of technology in this field.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025