Mobile:+86-311-808-126-83

Email:info@ydcastings.com

cf8m steel

CF8M Steel Properties, Applications, and Advantages

CF8M steel is a type of austenitic stainless steel, categorized under the ASTM A351 standard for castings. Known for its excellent corrosion resistance and durability, CF8M is primarily composed of chromium, nickel, and molybdenum, which enhance its overall performance in various environments. Often referred to as the casting equivalent of 316 stainless steel, CF8M is widely utilized in various industrial applications due to its favorable mechanical and physical properties.

CF8M Steel Properties, Applications, and Advantages

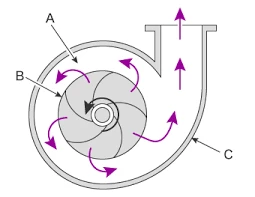

In terms of mechanical properties, CF8M offers superior strength and ductility. It typically exhibits good tensile strength and elongation, which are crucial for applications that demand both structural integrity and the ability to withstand stress and deformation. This makes CF8M suitable for various applications, including valves, pump components, and other fittings used in the chemical and petrochemical industries.

cf8m steel

The versatility of CF8M extends to its temperature resistance. It remains stable under high heat conditions, retaining its properties across a wide range of temperatures. This thermal stability is particularly important in industries such as oil and gas, where equipment may undergo fluctuating thermal conditions continually.

Moreover, CF8M steel is known for its ease of fabrication. It can be welded, machined, and formed into various shapes and sizes, making it adaptable to different manufacturing processes. Its ability to be cast into intricate designs allows engineers to create complex components that meet specific design parameters without compromising on performance.

However, it is important to note that while CF8M steel is highly adaptable, it does face certain limitations. It is not suitable for environments with high concentrations of hydrochloric acid or sulfuric acid, as these conditions can lead to rapid deterioration. Thus, it is essential for engineers and designers to assess the operational environment before choosing CF8M for their applications.

In summary, CF8M steel is a highly durable and versatile material that offers excellent resistance to corrosion, high strength, and thermal stability. Its applications span many industries, particularly in roles that require reliability under challenging conditions. With its favorable machining and fabrication properties, CF8M continues to be a popular choice for engineers seeking materials that can withstand the demands of modern industrial environments. As technology and industry standards evolve, CF8M steel will undoubtedly remain a critical component in the composition of advanced applications, ensuring safety and efficiency in various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025