Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Connections for Cast Iron Sewer Pipes in Plumbing Systems and Repair Techniques

Understanding Cast Iron Sewer Pipe Connections

Cast iron sewer pipes have been a staple in plumbing systems for over a century. Renowned for their durability, strength, and longevity, these pipes are commonly used in various wastewater applications, including drainage systems in residential and commercial buildings. One of the critical aspects of working with cast iron sewer pipes is the connection methods used to join individual pipe sections. Understanding these connections is essential for effective installation and maintenance.

Types of Connections

There are several types of connections used when working with cast iron sewer pipes, including those that utilize mechanical joints, hub-and-spigot systems, and no-hub couplings

. Each of these methods serves a specific purpose and has its advantages and disadvantages.1. Hub-and-Spigot Connections This traditional method involves fitting the spigot end of one pipe into the hub of another. The joint is typically sealed with a gasket or lead to prevent leaks. Hub-and-spigot connections are exceptionally strong and are ideal for underground installations where soil movement can impose stress on pipes. They also allow for some movement, which is a significant advantage in shifting soil conditions.

2. No-Hub Couplings These connections involve the use of a rubber sleeve and metal clamp to connect two pipes. This method is becoming increasingly popular due to its ease of installation and flexibility. No-hub couplings enable adjustments in alignment and are less sensitive to minor misalignments than traditional methods. They also simplify the replacement of damaged sections of piping, making maintenance more accessible.

3. Mechanical Joints Mechanical joints consist of a grooved end on one pipe that fits into a similarly grooved end on another, secured by a mechanical sleeve. This type of connection allows installers to join sections quickly without needing to weld or use cement, making it particularly beneficial in tight spaces or when rapid assembly is needed.

Advantages of Cast Iron Sewer Pipes

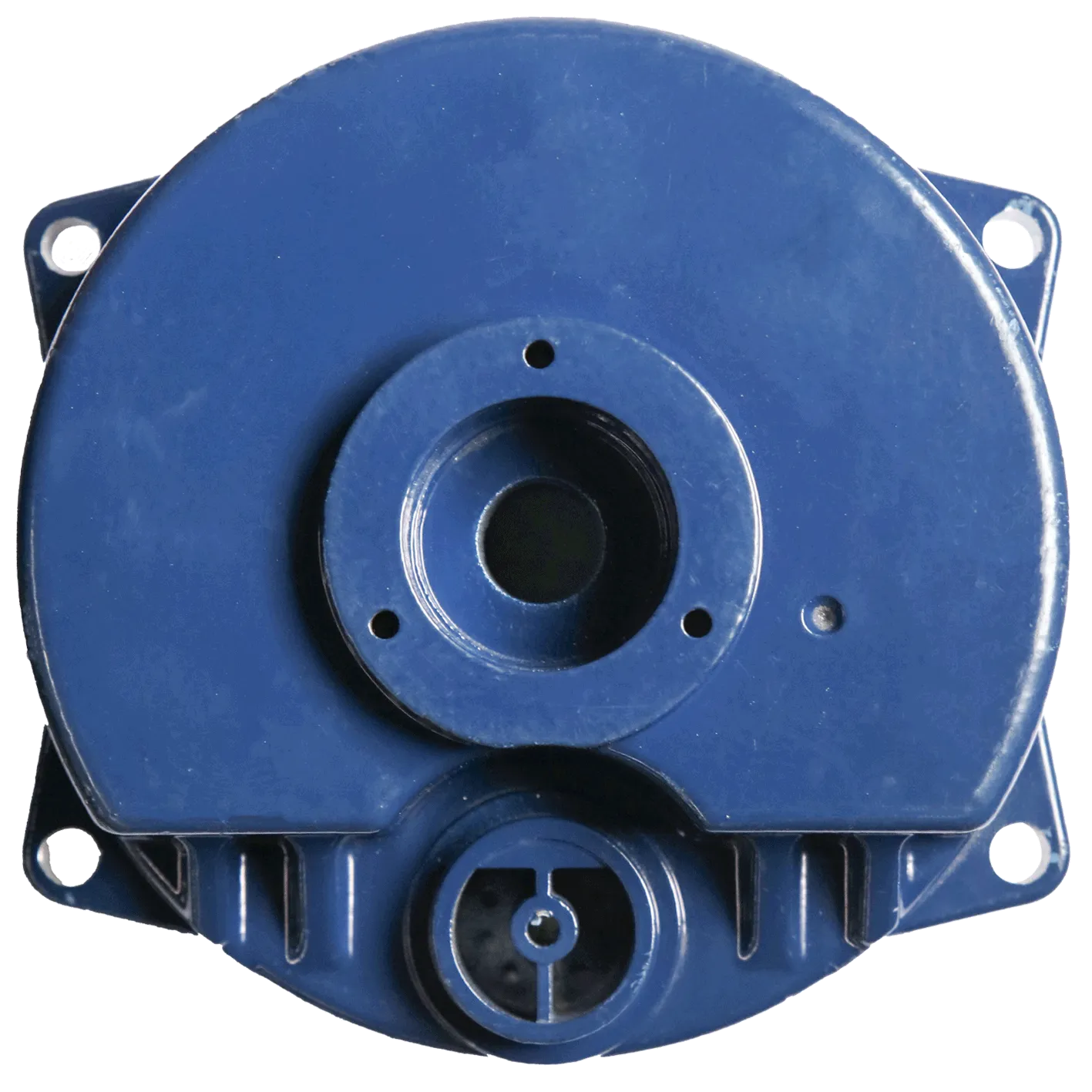

cast iron sewer pipe connections

The choice of cast iron sewer pipes primarily revolves around their robust nature. They are resistant to impact and temperature fluctuations, making them less susceptible to breaking or deforming compared to plastic piping. Moreover, cast iron pipes provide excellent sound attenuation, which is crucial in residential areas where noise from flowing sewage can be a concern.

Additionally, cast iron has a high resistance to corrosion, especially with modern coatings or treatments applied. This ensures a longer lifespan for pipes, often outlasting traditional plastic varieties by decades. While the initial installation cost of cast iron pipes may be higher, their longevity and reduced need for repairs can offer better value over time.

Considerations for Installation

When installing cast iron sewer pipes, it is crucial to consider the weight of the material. Cast iron is significantly heavier than other piping options, necessitating careful handling and appropriate support systems during installation to avoid stress fractures. Proper alignment during the connection process is also vital to ensure a watertight seal and to prevent potential leaks down the line.

Furthermore, local plumbing codes and regulations should always guide any installation plans. Compliance ensures the system's integrity and operational safety, protects public health, and contributes to environmental sustainability.

Conclusion

Cast iron sewer pipe connections remain a critical aspect of plumbing design and installation. Understanding the various connection methods, advantages of cast iron, and installation considerations empowers contractors and homeowners alike to make informed decisions. As plumbing technology continues to evolve, the traditional strength and reliability of cast iron ensure it remains relevant in today's construction landscape. Whether you're working on a new build or a renovation, cast iron sewer pipes stand the test of time, proving to be a foundational element in effective waste management.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025