Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Ene . 20, 2025 03:44

Back to list

Connector bracket

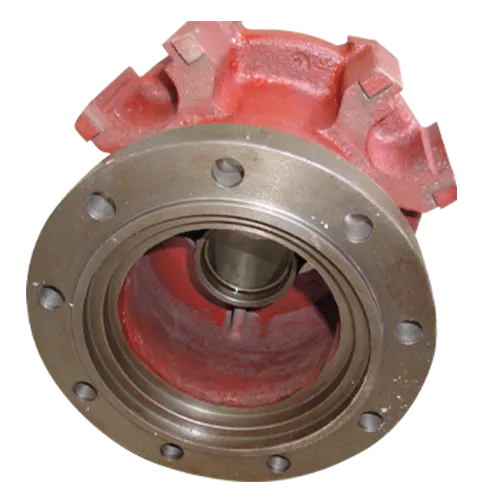

The cast impeller is a pivotal component in various industrial applications, where it plays an essential role in dictating the efficiency and performance of pumps. As an expert in the field of pump systems, I can attest to the significant impact a high-quality cast impeller can have on operational efficiency.

A reliable manufacturer will apply stringent quality checks during the production of cast impellers. It involves careful examination for defects such as porosity or imbalance, which could lead to premature failure or reduced performance. Employing advanced techniques like computer-aided design (CAD) and computational fluid dynamics (CFD) simulations further enhances the impeller's design, ensuring optimal performance tailored to specific operating conditions. Authority in the field of cast impellers also demands a commitment to continuous innovation. With advancements in technology, manufacturers are now experimenting with novel alloys and ceramic composites that offer superior wear resistance and efficiency. These innovations not only boost pump performance but also offer a sustainable solution by extending the life cycle of the pump components. Trustworthiness in the context of cast impellers can be measured by the track record of the supplier. Reputable suppliers provide extensive technical support, helping clients select the most appropriate impeller design and material for their unique needs. Moreover, they offer comprehensive after-sales services, including installation guidance and maintenance tips, which build long-term client relationships based on reliability and trust. In conclusion, the cast impeller is an indispensable component in the realm of pump technology. Its design, material selection, and manufacturing precision directly impact the efficiency and reliability of pumping systems across industries. Businesses seeking to optimize their pump operations would benefit significantly from collaborating with experienced suppliers who possess a deep understanding of the nuances of cast impellers. This partnership not only enhances operational efficiency but also ensures a robust return on investment by maximizing the lifespan and performance of the pumping systems.

A reliable manufacturer will apply stringent quality checks during the production of cast impellers. It involves careful examination for defects such as porosity or imbalance, which could lead to premature failure or reduced performance. Employing advanced techniques like computer-aided design (CAD) and computational fluid dynamics (CFD) simulations further enhances the impeller's design, ensuring optimal performance tailored to specific operating conditions. Authority in the field of cast impellers also demands a commitment to continuous innovation. With advancements in technology, manufacturers are now experimenting with novel alloys and ceramic composites that offer superior wear resistance and efficiency. These innovations not only boost pump performance but also offer a sustainable solution by extending the life cycle of the pump components. Trustworthiness in the context of cast impellers can be measured by the track record of the supplier. Reputable suppliers provide extensive technical support, helping clients select the most appropriate impeller design and material for their unique needs. Moreover, they offer comprehensive after-sales services, including installation guidance and maintenance tips, which build long-term client relationships based on reliability and trust. In conclusion, the cast impeller is an indispensable component in the realm of pump technology. Its design, material selection, and manufacturing precision directly impact the efficiency and reliability of pumping systems across industries. Businesses seeking to optimize their pump operations would benefit significantly from collaborating with experienced suppliers who possess a deep understanding of the nuances of cast impellers. This partnership not only enhances operational efficiency but also ensures a robust return on investment by maximizing the lifespan and performance of the pumping systems.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS