Mobile:+86-311-808-126-83

Email:info@ydcastings.com

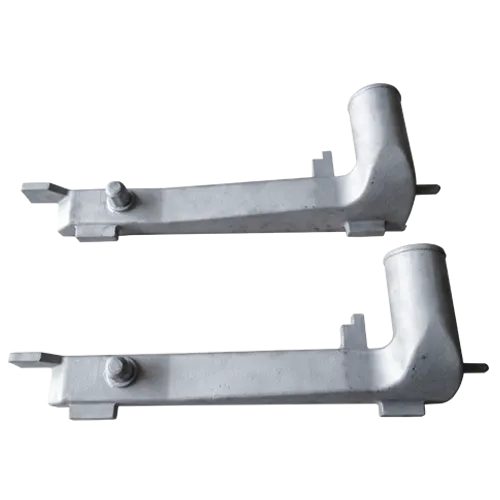

casing impeller

The Importance of Casing and Impeller in Pump Design

In the world of fluid mechanics and pump design, two critical components stand out the casing and the impeller. These parts play a vital role in ensuring the efficient operation of pumps, which are commonly used in various applications, from industrial processes to household water supply systems. Understanding the significance of these components can lead to better design choices, enhanced efficiency, and prolonged service life for pumps.

Understanding the Casing

The casing of a pump is the outer shell that houses the internal components, including the impeller, volute, and other necessary parts. It serves multiple functions protecting the internal mechanisms from external elements, maintaining the structural integrity of the pump, and guiding the fluid as it flows into and out of the pump. The design of the casing can significantly impact the overall performance of the pump.

Casing shapes vary widely depending on the intended application. For instance, a volute casing is commonly used in centrifugal pumps, where the casing is spiral-shaped to facilitate smooth fluid flow and reduce turbulence. This design allows for an efficient conversion of kinetic energy from the impeller into pressure energy, optimizing fluid transport.

The Role of the Impeller

The impeller is the heart of the pump, responsible for imparting energy to the fluid. It consists of rotating blades that absorb the input energy from the motor and convert it into kinetic energy, pushing the fluid through the casing. The design of the impeller—its size, shape, and material—directly affects the pump's performance, including flow rate and pressure output.

casing impeller

Different types of impellers are suited for various applications. For example, enclosed impellers are often used in applications requiring high efficiencies and better handling of solids, while open impellers excel in applications dealing with larger particles or fibrous materials. The choice of impeller design can significantly influence the pump's operational efficiency and reliability.

Importance of Integration

The integration of the casing and impeller is critical for the pump's overall efficiency. A well-matched casing and impeller minimize losses due to turbulence, cavitation, and incorrect flow patterns. Poor integration can lead to reduced performance, increased wear on components, and even premature pump failure.

Engineers must consider various factors during the design phase, including the properties of the fluid being pumped, the required flow rate, and the operating pressures. Advanced computational fluid dynamics (CFD) simulations can aid in better understanding the interaction between the casing and impeller, allowing for more precise designs that maximize efficiency and longevity.

Conclusion

In conclusion, the casing and impeller are essential components in pump design that work in tandem to ensure efficient fluid transport. A thorough understanding of their functions and the importance of their integration can lead to better-performing pumps that meet the demands of various applications. As technology continues to evolve, ongoing research and innovation in casing and impeller design will play a crucial role in enhancing the efficiency and reliability of pumping systems worldwide. By prioritizing optimal design choices, industries can achieve greater energy savings and operational effectiveness while extending the lifespan of their equipment.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025