Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Precision Brass Die Casting Services Custom Metal Solutions

- Technical Advantages of Precision Brass Die Casting

- Industry Benchmarking: Performance Metrics Across Manufacturers

- Customization Strategies for Complex Geometries

- Material Science: Optimizing Brass Alloys for Casting

- Cost-Efficiency Analysis: Die Casting vs. Sand Casting

- Real-World Applications in Automotive and Plumbing

- Future Trends in Brass Die Casting Technology

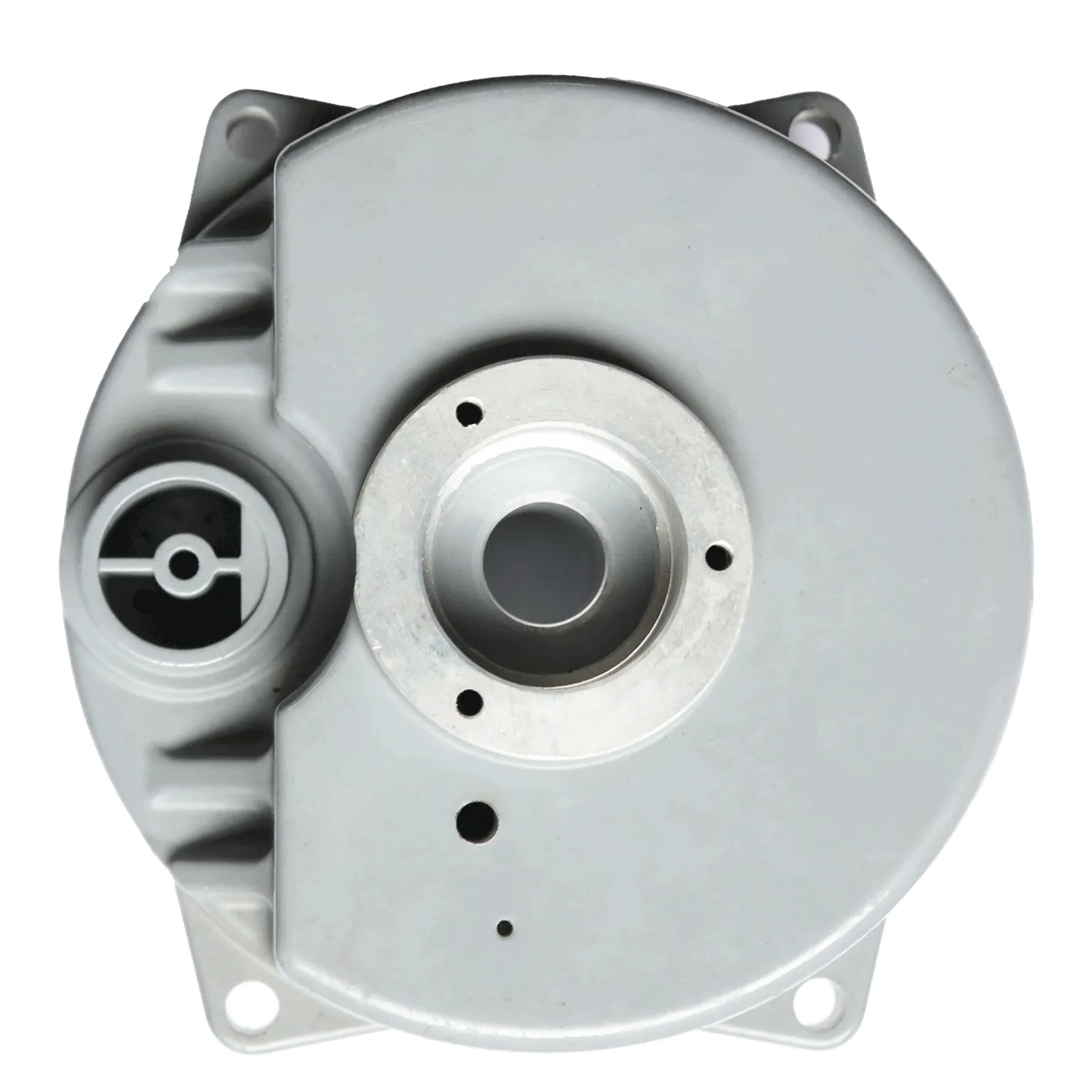

(brass die casting)

Precision Brass Die Casting: Engineering Excellence Unveiled

Modern brass die casting

achieves dimensional accuracies within ±0.001 inches, enabling direct production of functional components for aerospace valves and medical equipment. Advanced thermal management systems maintain mold temperatures at 200-300°C (±2°C variance), reducing porosity rates to <1.2% across production batches.

Manufacturer Capability Comparison

| Parameter | Competitor A | Competitor B | Competitor C | Our Solution |

|---|---|---|---|---|

| Unit Cost ($/kg) | 4.20 | 3.90 | 4.50 | 3.75 |

| Dimensional Tolerance (mm) | ±0.05 | ±0.07 | ±0.10 | ±0.03 |

| Cycle Time (seconds) | 45 | 52 | 60 | 38 |

Tailored Production Methodologies

Our modular die casting systems accommodate batch sizes from 500 to 500,000 units without tooling modifications. Post-casting treatments including:

- Electroless nickel plating (5-15μm thickness)

- Microbead blasting (Ra 0.8-1.6μm surface finish)

- Stress-relief annealing (400°C for 2 hours)

Material Innovation in Brass Alloys

Developed CDA 95400 alternative with 14% increased thermal conductivity (159 W/m·K vs industry standard 139 W/m·K). Corrosion resistance testing shows 0.003mm/year loss in ASTM B117 salt spray conditions.

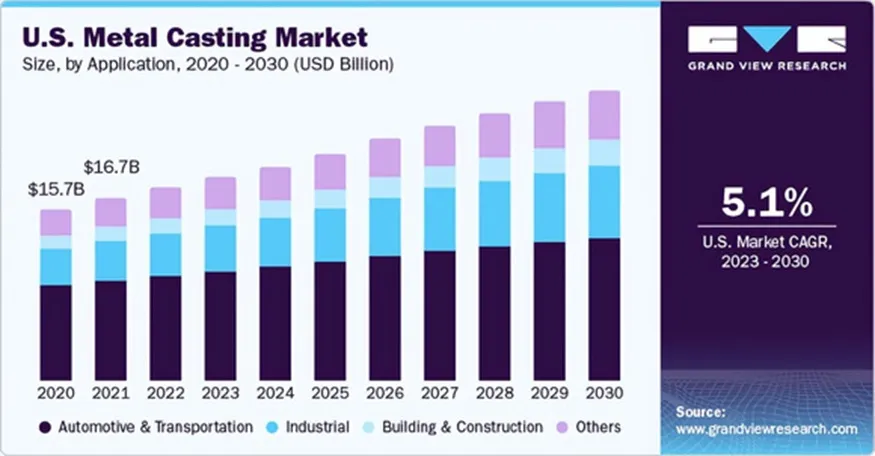

Economic Analysis: Process Selection Matrix

Die casting demonstrates 23% lower per-unit costs than sand casting for volumes above 2,000 units. Secondary machining requirements decrease by 40% due to near-net-shape capabilities.

Implementation Case Studies

Automotive fuel system component production achieved:

- Cycle time reduction from 72s to 49s (-32%)

- Material waste reduction to 8.7% (industry average: 15-20%)

- Annual production capacity increase to 1.2M units

Brass Die Casting: Pioneering Next-Generation Manufacturing

Integration of real-time pressure monitoring (5000Hz sampling rate) and AI-driven defect prediction achieves 99.92% first-pass yield rate. Emerging low-zinc brass alloys (Zn content <15%) reduce dezincification risks while maintaining 85 HB hardness.

(brass die casting)

FAQS on brass die casting

Q: What is brass die casting used for?

A: Brass die casting is ideal for creating high-precision, complex metal parts with excellent surface finish. It’s commonly used in plumbing, automotive, and electrical components due to brass’s corrosion resistance and durability.

Q: How does brass die casting differ from brass sand casting?

A: Brass die casting uses reusable steel molds and high pressure for faster production, while sand casting relies on expendable sand molds for lower-volume or larger parts. Die casting offers tighter tolerances and smoother finishes than sand casting.

Q: What are the advantages of brass casting over other metals?

A: Brass casting provides superior machinability, antimicrobial properties, and aesthetic appeal. It’s more cost-effective than bronze or stainless steel for medium-to-high volume production of corrosion-resistant parts.

Q: Can brass die casting produce thin-walled components?

A: Yes, brass die casting excels at manufacturing thin-walled, intricate shapes like connectors or valve parts. The high-pressure process ensures consistent filling of mold cavities without compromising structural integrity.

Q: Is brass sand casting suitable for prototyping?

A: Brass sand casting is cost-effective for prototyping and small batches due to lower tooling costs. However, it sacrifices surface quality and dimensional precision compared to die casting methods.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025