Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimization of Blower Fan Impeller Design for Enhanced Performance and Efficiency

Understanding Blower Fan Impellers Design, Function, and Applications

Blower fan impellers are critical components in various ventilation and cooling systems. They play a pivotal role in generating airflow by converting rotational energy from a motor into kinetic energy of the air. Understanding the design, function, and applications of blower fan impellers is essential for choosing the right system for specific needs.

Design of Blower Fan Impellers

The design of a blower fan impeller is fundamental to its efficiency and performance. Impellers can be classified into two primary categories centrifugal and axial.

1. Centrifugal Impellers These impellers work by thrusting air radially outward using a series of blades that are shaped to impart centrifugal force on the air. The geometry of the blades, including their length, thickness, and angle, significantly affects the airflow rate and pressure generated. The higher the rotational speed, generally, the greater the airflow.

2. Axial Impellers Axial impellers have blades arranged parallel to the axis of rotation. These impellers draw air in along the axis and propel it axially. They are typically used in applications where high flow rates with relatively low pressure increases are required. The blade design in axial impellers can vary, allowing for adjustments in the airflow characteristics based on the application's needs.

Materials used in manufacturing impellers include metals, plastics, and composites, each chosen for specific durability, weight, and resistance to environmental factors like temperature and corrosion.

Function of Blower Fan Impellers

The primary function of a blower fan impeller is to move air or gas efficiently through a system. This movement is essential for various applications, including

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) applications, blower fan impellers help circulate air, ensuring comfortable indoor environments by maintaining optimal temperatures and air quality

.- Industrial Processes In manufacturing, many processes generate heat or require a controlled environment. Impellers help manage temperature and keep equipment cool, increasing operational efficiency and equipment longevity.

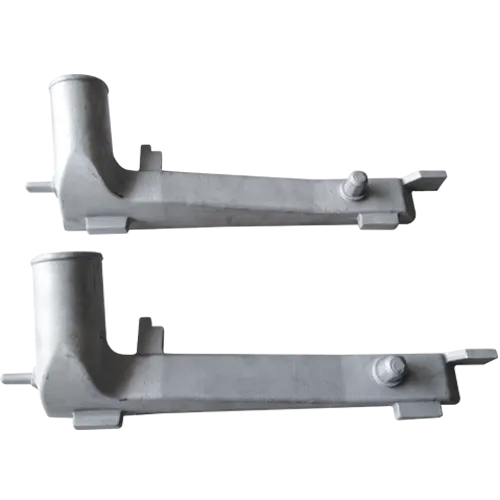

blower fan impeller

- Dust and Fume Control In industries such as woodworking or chemical processing, blower fan impellers are used to remove dust, fumes, and other airborne contaminants, ensuring a safer work environment.

- Cooling Systems In electronic and mechanical equipment, cooling fans, which include blower impellers, are essential to prevent overheating and maintain reliable operation.

Applications of Blower Fan Impellers

Blower fan impellers are utilized in a vast range of industries and applications.

1. Residential Applications Commonly found in household HVAC systems and kitchen exhaust fans, they help maintain air quality and thermal comfort.

2. Commercial Buildings In larger buildings, central air handling units equipped with blower fan impellers are used to manage heating and cooling efficiently.

3. Automotive Industry Cooling fans, powered by blower impellers, are critical for regulating engine temperature and ensuring efficient operation.

4. Aerospace and Aviation In aircraft, blowers are used to circulate air in the cabin and ensure proper functioning of various systems, requiring highly efficient impeller designs.

Conclusion

Blower fan impellers are indispensable components that serve numerous critical functions across different sectors. Their design and operational efficiency greatly influence air movement within systems, making them essential for maintaining comfortable, safe, and efficient environments. Whether in residential spaces, commercial buildings, or industrial processes, understanding the intricacies of blower fan impellers enables users to make informed decisions about ventilation and cooling systems, ultimately leading to improved performance and energy efficiency. As technology advances, the design and materials used for blower fan impellers will continue to evolve, paving the way for even more efficient and versatile ventilation solutions.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025