Mobile:+86-311-808-126-83

Email:info@ydcastings.com

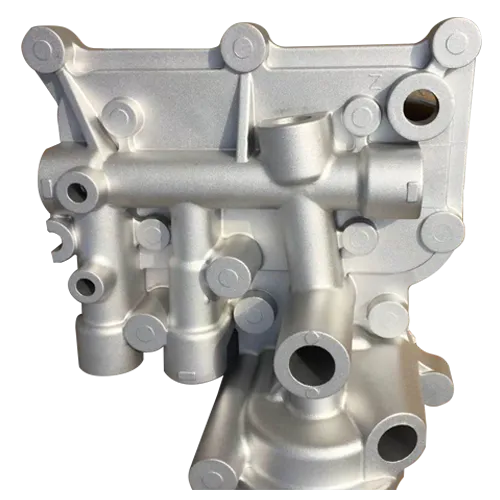

automotive water pump rebuilding

Rebuilding an Automotive Water Pump A Comprehensive Guide

The automotive water pump plays a crucial role in maintaining the engine's cooling system, ensuring optimal temperature and performance. Over time, wear and tear can lead to decreased efficiency or failure of the water pump. In such cases, rebuilding the water pump can be a cost-effective solution. This article walks you through the steps and considerations involved in the rebuilding process.

Understanding the Water Pump Function

The primary function of a water pump is to circulate coolant throughout the engine and radiator system. This helps absorb excess heat and maintain an optimal operating temperature. A failing water pump can lead to overheating, which may cause significant engine damage. Therefore, recognizing the signs of a malfunctioning pump, like coolant leaks, unusual noises, or engine overheating, is vital.

Disassembling the Water Pump

Before embarking on the rebuilding journey, it's essential to gather the necessary tools, which typically include wrenches, socket sets, screwdrivers, gaskets, and a sealant. Ensure you have a clean workspace and follow safety protocols, such as disconnecting the battery and relieving any pressure in the cooling system.

1. Remove the Water Pump Carefully detach the water pump from the engine by loosening the bolts that secure it. Be prepared for some coolant spillage, so have a drain pan ready.

2. Inspect for Damage Once removed, inspect the water pump for any visible damage, such as cracks, corrosion, or wear in the bearings. This evaluation will inform your decision on whether to rebuild or replace.

Rebuilding Process

automotive water pump rebuilding

If the water pump shows signs of being rebuildable, follow these steps

1. Clean the Components Use a cleaning solvent to remove any old gaskets, dirt, and debris from the pump and associated parts. A clean surface is essential for proper sealing.

2. Replace Seals and Gaskets Most water pumps include various seals and gaskets that can wear out over time. Replace these components with high-quality parts to prevent future leaks.

3. Inspect the Impeller The impeller should be cleaned and inspected for wear. If it’s damaged beyond a repairable state, it may need to be replaced.

4. Reassemble the Water Pump Carefully reattach all components, ensuring that the gaskets and seals are correctly positioned. Apply sealant as required and tighten bolts to the manufacturer’s specified torque settings.

Reinstallation and Testing

With the pump rebuilt, reinstall it onto the engine, ensuring all bolts are securely fastened. Reconnect the coolant hoses, and fill the system with fresh coolant. Start the engine and monitor for leaks or abnormal noises, ensuring that the pump is functioning correctly.

Conclusion

Rebuilding an automotive water pump can be a rewarding project that saves money and extends the life of your vehicle. By understanding the components and the rebuilding process, car enthusiasts can perform this task effectively and maintain their engine in peak condition. Remember, if in doubt about any stage of the process, consulting a professional mechanic is advisable to ensure safety and reliability.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025